1. BARCODE PRINTER...................................................................4

1-1. Box content.....................................................................................................................4

1-2. Specifications..................................................................................................................4

1-3. Interfaces ........................................................................................................................6

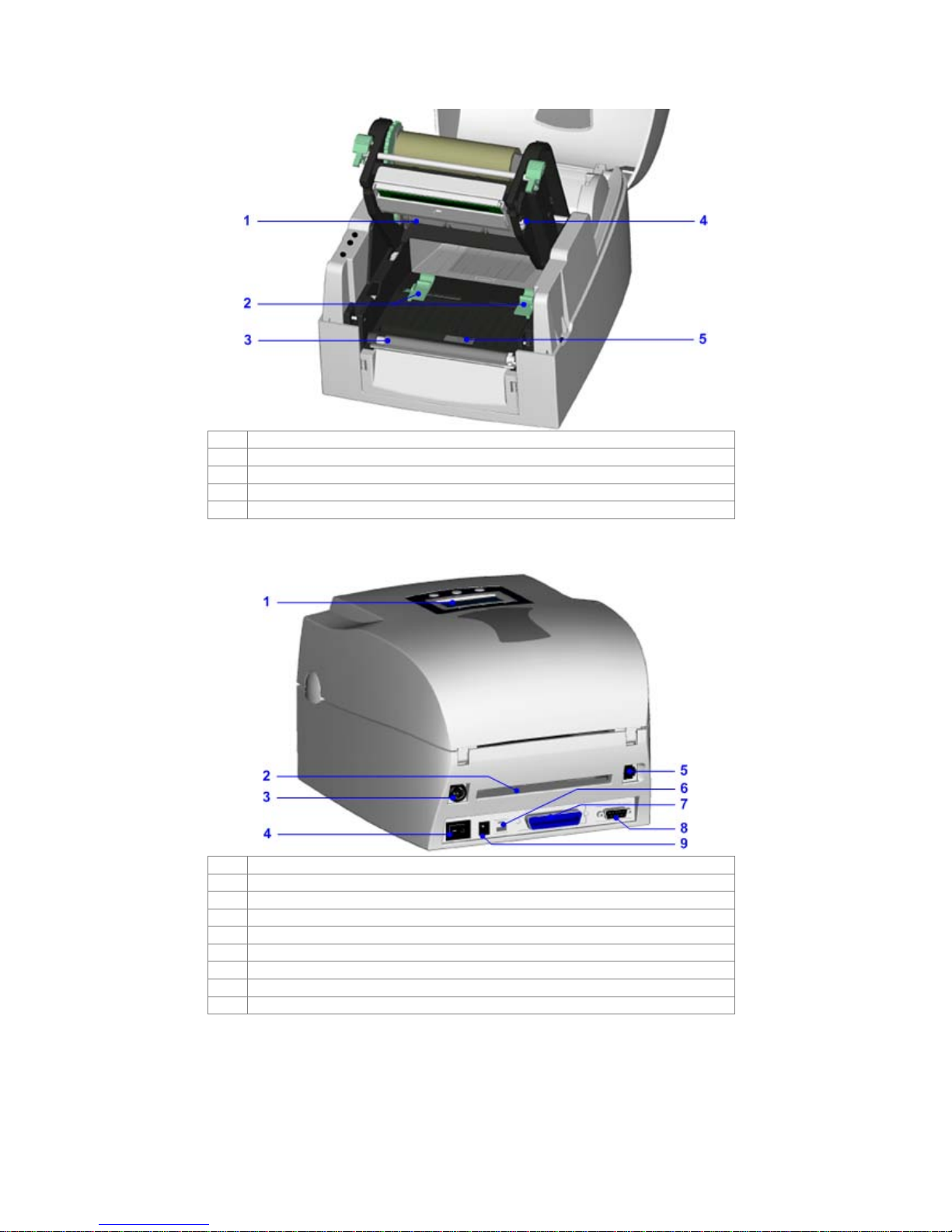

1-4. Getting to know your printer............................................................................................8

2. PRINTER SETUP....................................................................... 10

2-1. Loading the ribbon........................................................................................................10

2-2. Loading the label roll.....................................................................................................12

2-3. Installing the label supply hub.......................................................................................13

2-4. Preparing for tag printing ..............................................................................................14

2-5. Connecting the printer to the host computer.................................................................14

2-6. Installing the driver........................................................................................................15

3. OPERATOR PANEL..................................................................17

3-1. Operator panel – introduction.......................................................................................17

3-2. Function buttons ...........................................................................................................17

3-3. Settings mode...............................................................................................................19

3-4. Self test.........................................................................................................................24

3-5. Dump mode ..................................................................................................................25

3-6. Label size calibration ....................................................................................................25

3-7. Keyboard mode.............................................................................................................26

3-8. Error alerts ....................................................................................................................29

4. ACCESSORIES.......................................................................... 30

4-1. Installing the label dispenser ........................................................................................30

4-2. Installing the cutter........................................................................................................33

4-3. Installing the WLAN module .........................................................................................35

4-4. Installing the CF card adapter.......................................................................................39

4-5. Instructions for using the CF card.................................................................................40

5. MAINTENANCE AND ADJUSTMENT....................................... 41

5-1. Cleaning the print head.................................................................................................41

5-2. Adjusting the print head pressure.................................................................................41

5-3. Adjusting the print line...................................................................................................42

5-4. Adjusting the cutter.......................................................................................................42

5-5. Troubleshooting............................................................................................................43