2

Table of Contents

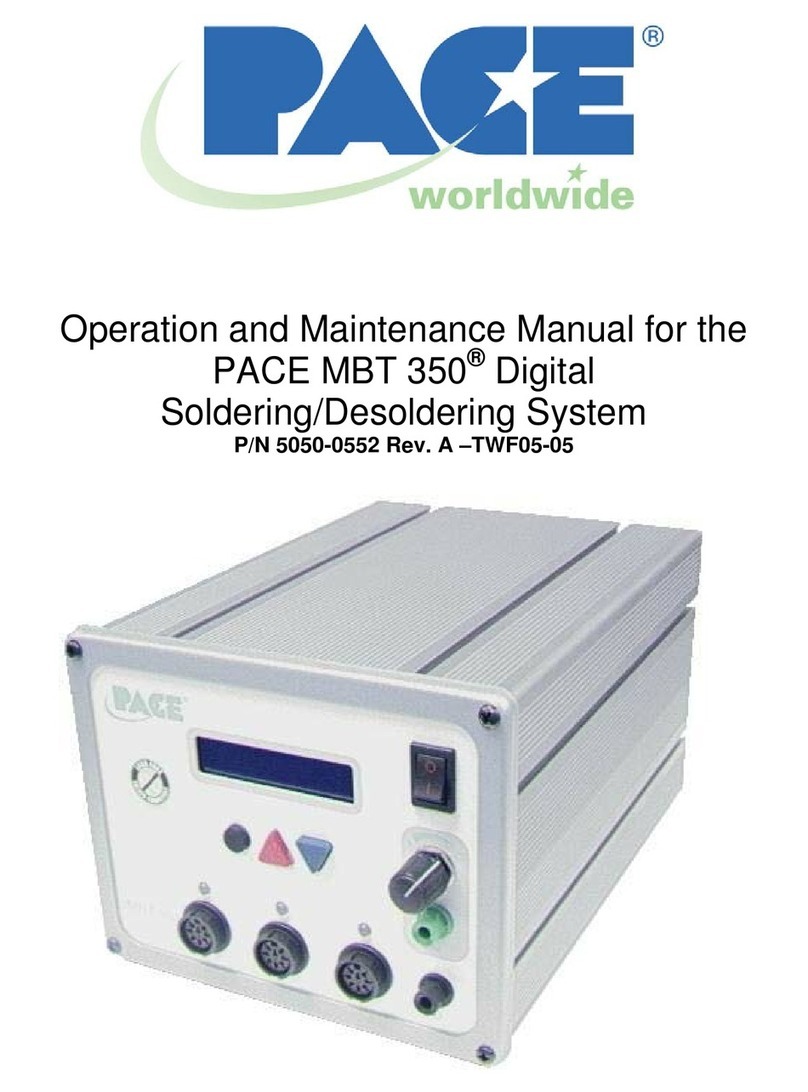

TITLE PAGE

GeneralInformation ................................................................................................. 4

Introduction ................................................................................................. 4

Specifications ............................................................................................... 4

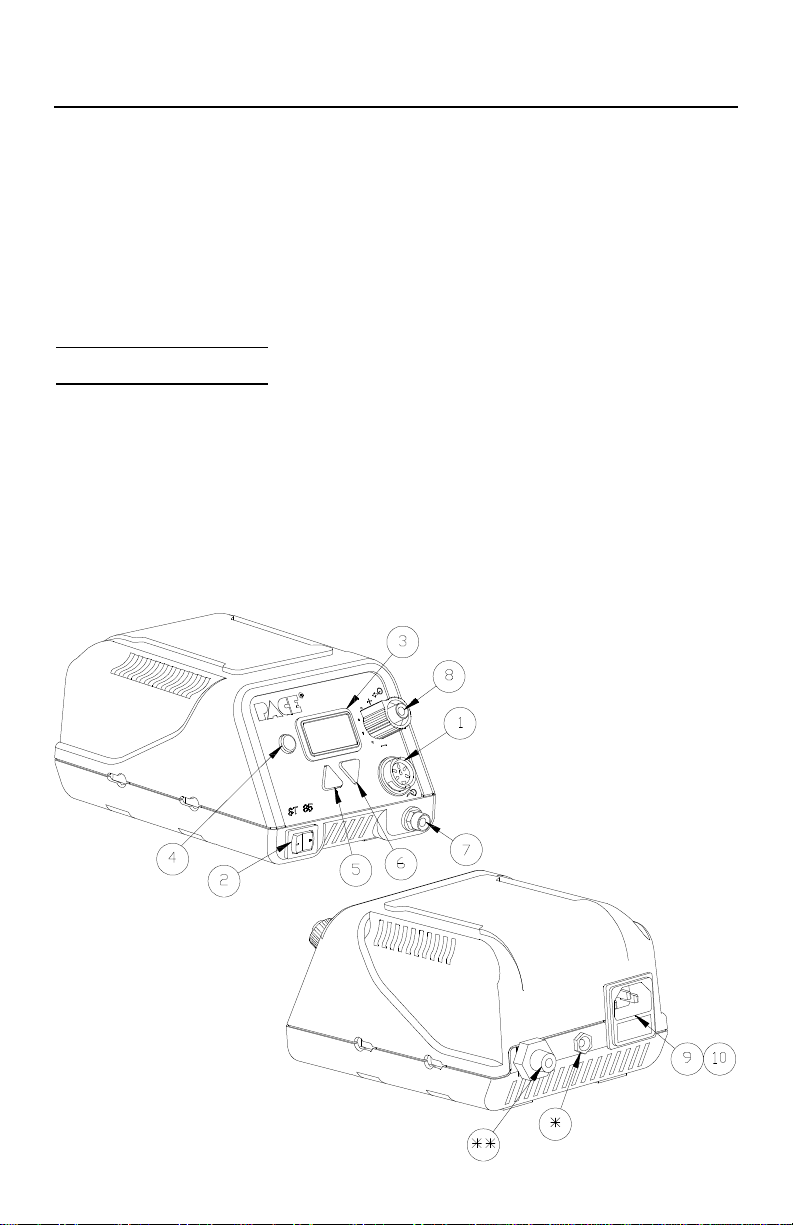

Parts Identification ....................................................................................... 5

Safety ...................................................................................................................... 6

Safety Guidelines, English Language ........................................................... 6

Safety Guidelines, French Language ............................................................ 7

SafetyGuidelines,GermanLanguage ........................................................... 8

Safety Guidelines, Italian Language ............................................................. 9

Safety Guidelines, Portuguese Language ....................................................10

Safety Guidelines, Spanish Language .........................................................11

Safety Guidelines, Swedish Language .........................................................12

Set-Up ....................................................................................................................13

Stacking.......................................................................................................13

Tip & Tool Stand .........................................................................................13

Air Supply Connection................................................................................14

Handpiece Vacuum/Pressure .......................................................................15

Handpiece Connection ................................................................................17

System Power Up ........................................................................................17

Heater Burn In .............................................................................................17

QuickStart-BasicOperation .................................................................................19

Introduction ................................................................................................19

QuickStart Procedure ..................................................................................19

Operation ...............................................................................................................20

Definitions...................................................................................................20

Password .....................................................................................................21

Auto Tip Temperature Compensation .........................................................21

LEDDisplay-NormalOperation .................................................................22

LED Display - TemperatureAdjust Mode....................................................23

TemperatureSetback ...................................................................................24

Activation ..............................................................................................24

Operation ...............................................................................................24

ExitingTemperatureSetback ..................................................................25

Auto Off Safety System...............................................................................25

Operation ...............................................................................................25

ExitingAutoOff .....................................................................................25

QuickTour ...................................................................................................26

Factory Settings ..........................................................................................28

LEDDisplayAccuracy ................................................................................28