2

1 General Information ........................................................................................................5

1.1 Safety – Notes on the Warranty................................................................................5

1.1.1 Set-up and Instruction.....................................................................................5

1.1.2 Proper Use ......................................................................................................7

1.1.3 Natural Wear...................................................................................................8

1.1.4 Potential Sources of Danger............................................................................8

1.1.5 Workplace.......................................................................................................9

1.1.6 Authorised Users.............................................................................................9

1.1.7 Protective Clothing and Equipment.................................................................9

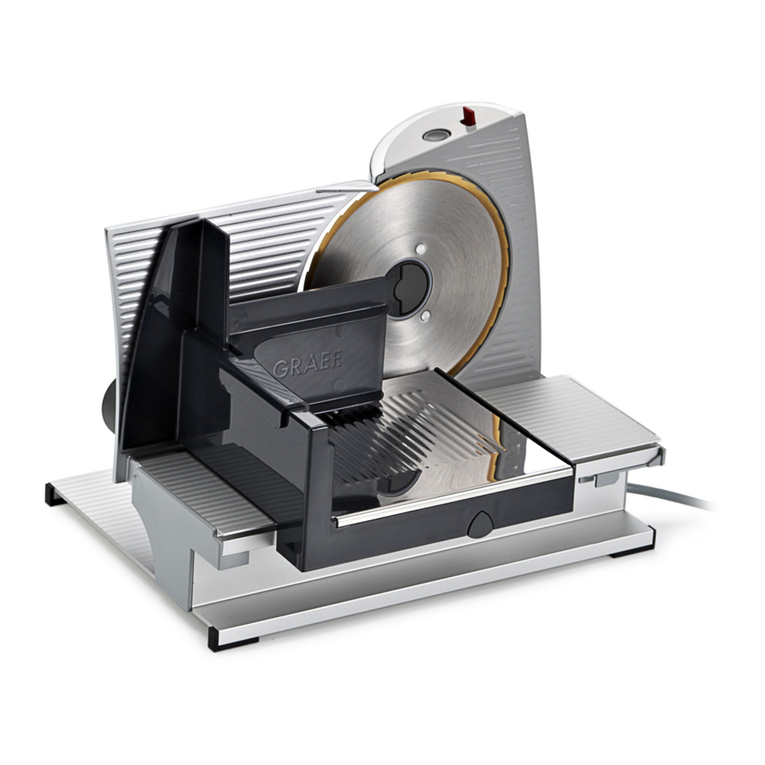

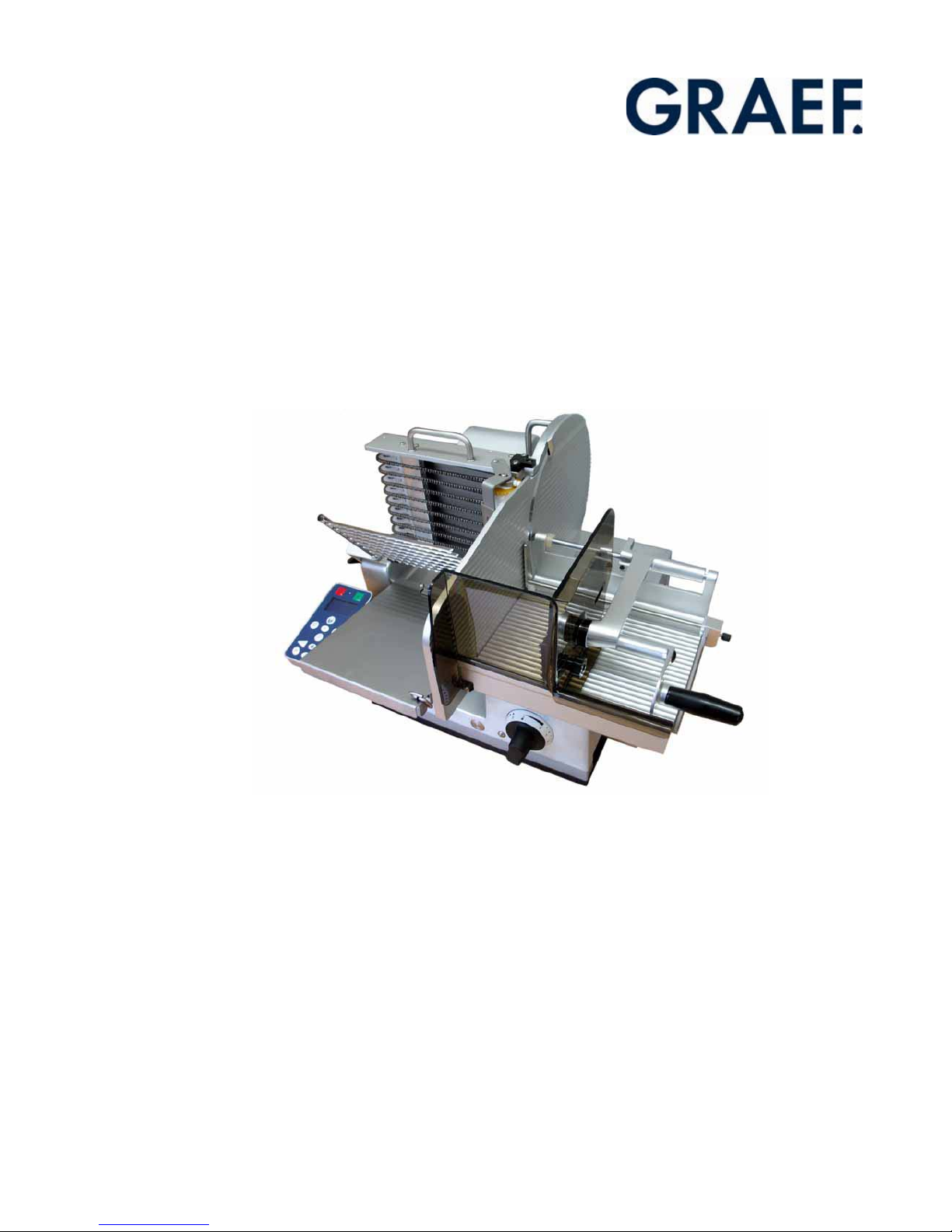

2 Description.....................................................................................................................10

2.1 Designation of the Machine Parts ...........................................................................10

2.2 Protective Devices...................................................................................................11

2.3 Technical data.........................................................................................................12

2.4 Basic Machine Equipment.......................................................................................13

2.5 Options ...................................................................................................................14

2.5.1 Additional Menu Standard Functions............................................................14

2.5.2 PLU Programming .........................................................................................14

3 Operation.......................................................................................................................15

3.1 Operating Controls..................................................................................................15

3.1.1 Operating Console ........................................................................................15

3.2 Programs.................................................................................................................17

3.2.1 Slicing in the Standard Mode (PLU 0000)......................................................17

3.2.2 Offset Function (Machines without Calibration Recognition)........................20

3.3 Using the Paper Clamp ...........................................................................................21

3.4 Slicing .....................................................................................................................21

3.5 HA 810 with Vario-Slice Carriage............................................................................23

3.5.1 Tilting the Carriage to the V Position ............................................................24

3.5.2 Tilting the Carriage to the Normal Position...................................................24

3.5.3 Cutting with the VS Carriage ........................................................................25

3.6 The Start Program ...................................................................................................25

3.7 Changing the Standard Program (PLU=0000).........................................................27

3.7.1 The “M+PLU” Additional Menu ...................................................................27

3.7.2 The “M” Additional Menu (OPTION HA 800) ...............................................30

3.7.3 Slicing in the PLU Mode ................................................................................34

3.7.4 Programming a PLU ......................................................................................35

4 Cleaning ........................................................................................................................40

4.1 Preparing for Cleaning ............................................................................................40

4.1.1 Disassembly of the Removable Parts.............................................................41

4.2 Cleaning the Different Parts of the Machine ...........................................................43

4.2.1 Blade and Blade Ring....................................................................................43

4.2.2 Carriage ........................................................................................................44

4.2.3 Chain Frame..................................................................................................45

4.3 Cleaning Schedule...................................................................................................47