4. Do not overload your unit

Your work is safer and better if kept within the stated range of capacity.

5. Use a correct tool

Do not use low-capacity machines or additional tools for hard works. Do not use for any works it has not been designed for.

6. Wear appropriate work clothing

Avoid wearing loose-fitting clothes or jewels that could be caught by rotating parts. If your hair is long, always wear a hairnet.

7. Use goggles

Always work wearing goggles to be protected against eyes injury.

8. Secure the piece worked

Use clamping fixtures to hold the piece.

9. Take proper care of the unit

Keep it sharp and clean so that work is better and safer. Follow maintenance regulations contained in the operating manual.

Check the plug and cable regularly and have them replaced by a professional if damaged. Keep the handles free of any oil and

grease.

10. Unplug the unit

Unplug the unit before getting down to any repairs or replacement of accessories or if it is to be out of use for some time.

11. Do not leave any wrenches, spanners and adjustment tools in the unit.

Check the unit before every switching on to make sure that the wrenches and adjustment tools have been removed.

12. Make provisions preventing unintentional switching on. Always pay attention to the machine having been put off by the

switches before you plug in.

13. When working outdoor, use special extension cables. For the use outdoor, you will need special extension cables fitting the

purpose and marked in an appropriate way.

14. Be attentive any time.

Mind what you are doing. Use common sense. Do not use the unit when tired.

15. Use of stare parts

Use only the spare parts expressly required or recommend by the manufacture. Use of other parts may result in a risk for the

user.

16. Make sure that the speed shown on the grinding tool are the same or higher than those shown as rated speed of the unit.

17. Make sure that the grinding tool size matches the unit.

18. Grinding discs require careful storage and handing.

19. The sharpeners have to be attached according to the data in the instruction manual.

20. With the tool newly fitted, let it run idle for about 30 sec. Mind the vibration possibly arising and if they are heavy, switch the unit

off. Check for the reason, remove it and re-test before using the unit again.

21. If protection devices are supplied with unit, the unit is allowed for use with the devices only.

22. Do not use other than prescribed grinding tool, not even with reducers or adaptors.

Behaviour in case of emergency

Apply the first aid adequate to the injury and get qualified medical assistance as quickly as possible. Protect the injured person from

more accidents and calm him/her down.

For the sake of eventual accident, in accordance with DIN 13164, a workplace has to be fitted with a first-aid kit. It is

essential to replace any used material in the first-aid kit immediately after it has been used. If you seek help, state the

following pieces of information:

1. Accident site

2. Accident type

3. Number of injured persons

4. Injury type(s)

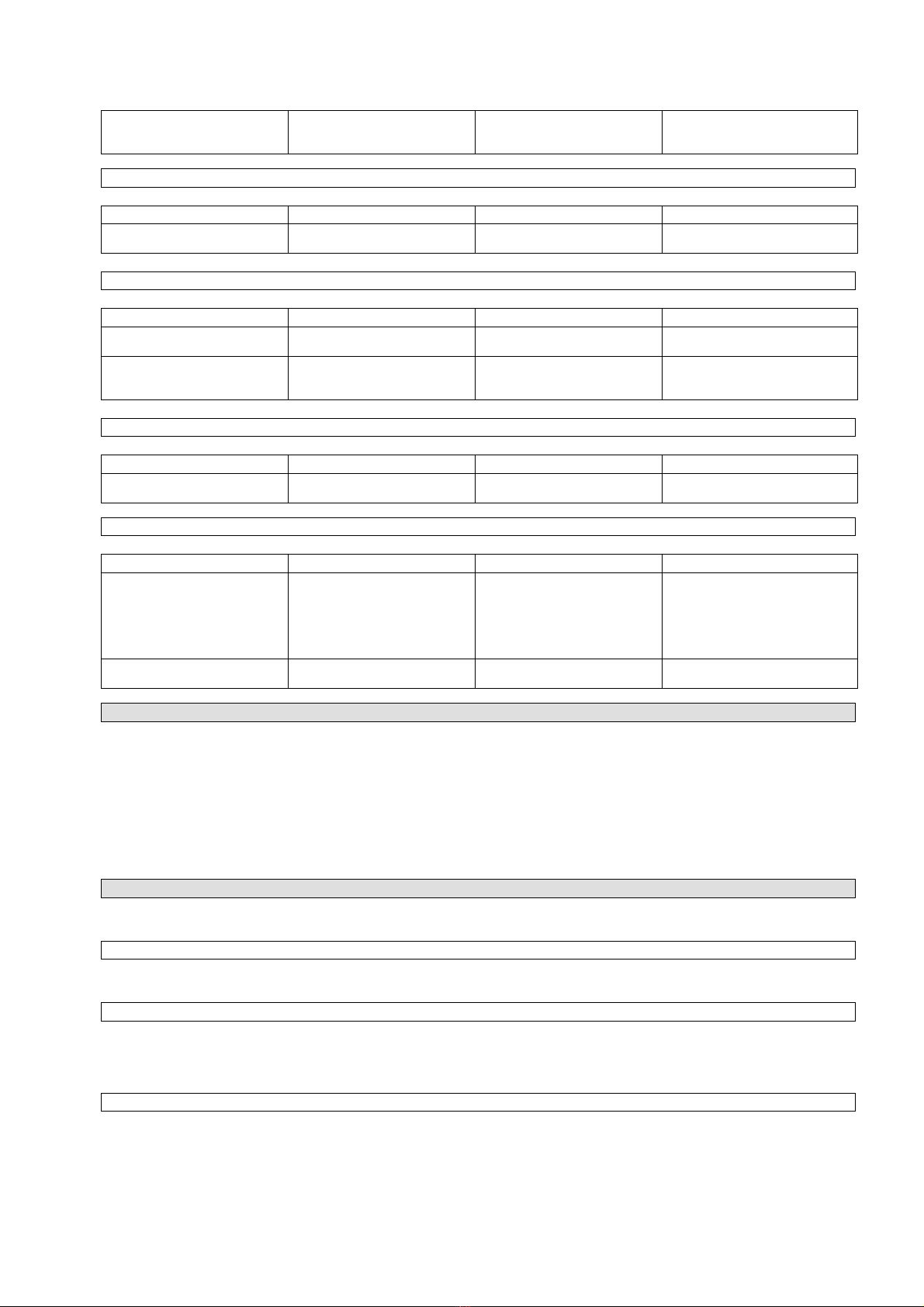

Sings on Unit

Meaning of Symbols

Symbols shown below are used throughout this manual and/or on the unit:

Product Safety:

Product compliance

with respective EU

standards Protection insulation

Bans:

General ban

(combined with

another pictograph

Do not reach in

rotating parts Do not use the unit

in rain Keep out of reach of

children Don´t pull the cable