only the selected cutting tool to the shaft

and turn the cutting tool so that it drops into

its coupling.

If using the pusher plate (1:A) fit the drilling

sleeve (1:J) by turning it anti-clockwise onto

the centre shaft of the cutting tool,

alternatively, if using the feed hopper (1:N) fit

the stirring sleeve (1:M) by turning it anti-

clockwise onto the centre shaft of the cutting

tool.

Lower the feed cylinder (1:C) alternatively

1:O) and turn the locking knob (1:B)

clockwise to the locked position.

REMOVING THE CUTTING TOOLS

Raise the pusher plate (1:A) and swing it out

to the left, or remove the feed hopper (1:N).

Turn the locking knob (1:B) anti-clockwise

and raise the feed cylinder (1:C) alternatively

(1:O).

Remove the drilling sleeve (1:J) alternatively

the stirring sleeve (1:M) by turning it

clockwise by means of the spanner (1:K).

Remove the cutting tool/tools and the

ejector plate (1:D).

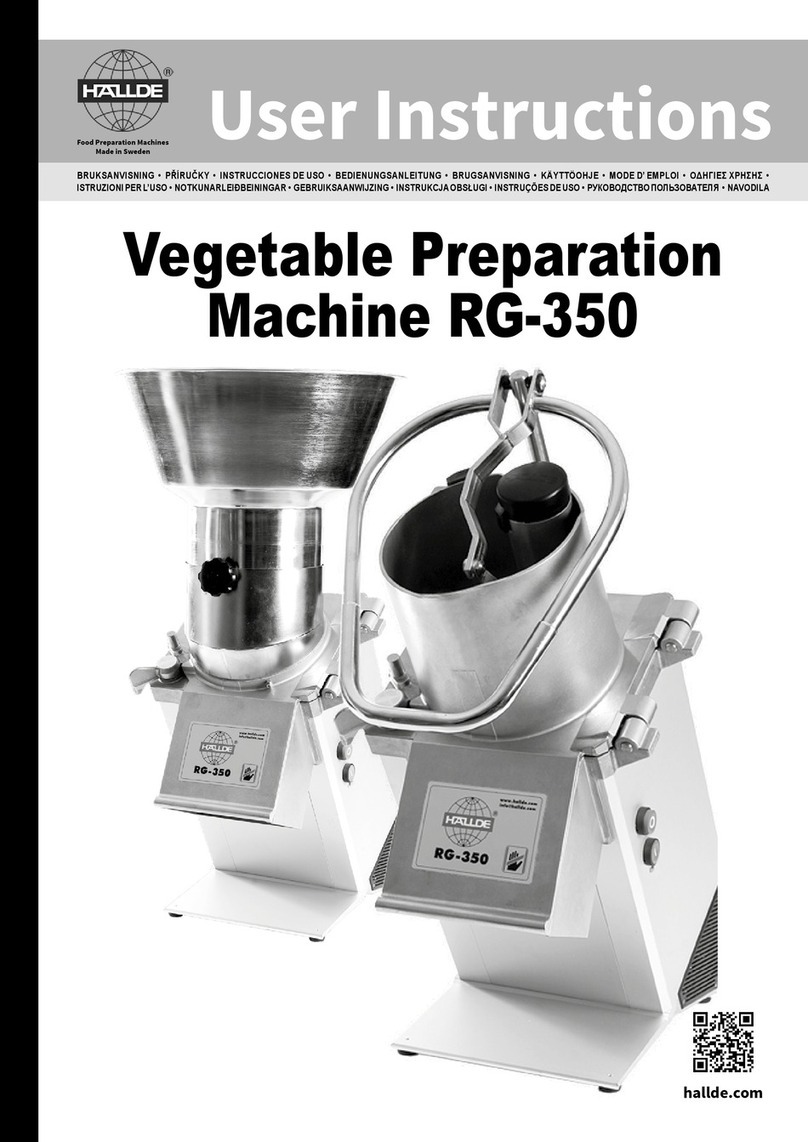

USING THE FEEDERS

Feed cylinder with push feeder:

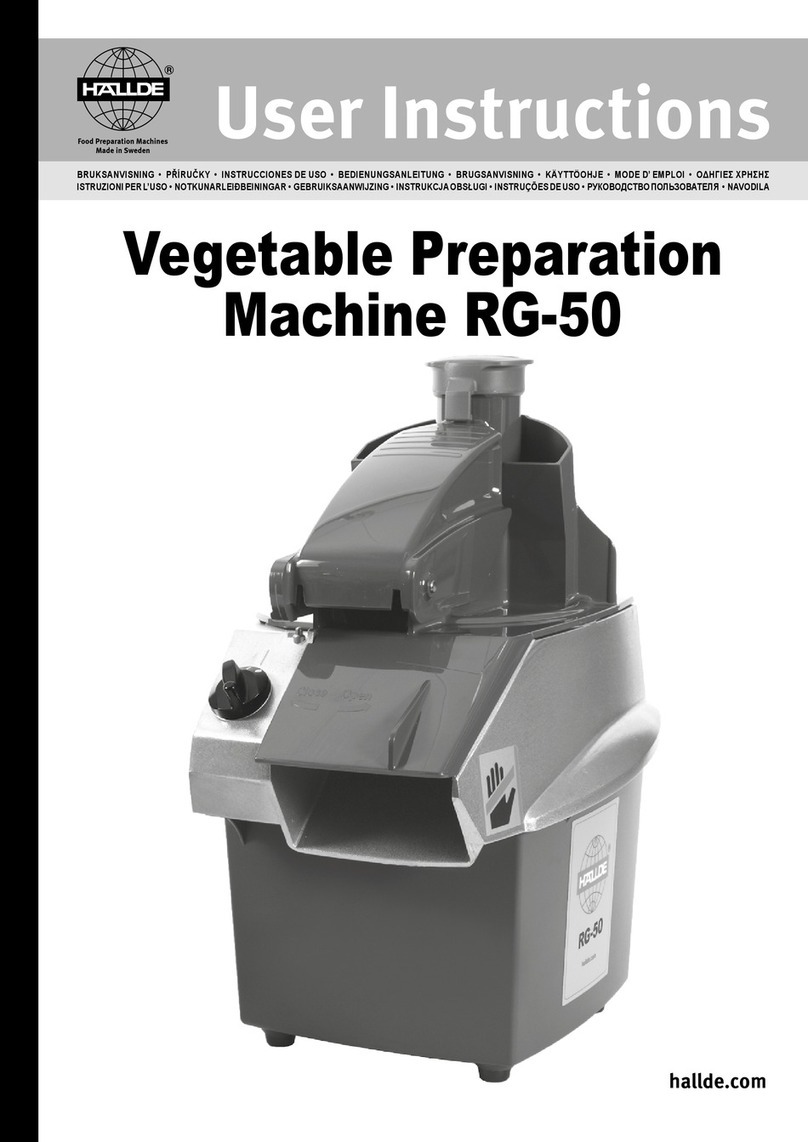

The large feed compartment is used mainly

for bulk feeding of most kinds of products

(2:C) and for cutting larger products such as

cabbage.

The large feed compartment is also used

when the material is to be cut in a definite

direction, such as tomatoes and lemons.

Place/stack the products as shown in the

figure (3:D).

The feed tube is used for cutting long

products such as cucumbers (3:E).

Feed cylinder with feed hopper:

The feed hopper (3:C) is used for continuous

feeding/cutting of large quantities of

potatoes, onions, dry bread, nuts,

mushrooms, etc.

CLEANING

Switch off the machine and remove the

power supply plug from the socket.

Carefully clean the machine immediately

after use.

If the cutting tools are marked "diwash",

read and follow the special "diwash" user

instruction manual carefully.

Never wash light metal items in the

dishwasher unless they are marked “diwash”.

If you have used a dicing grid (2:G), leave it

in the machine, and use the brush (3:B) for

pushing out any dices remaining in the grid.

Remove the loose parts of the machine, wash

them and dry them thoroughly.

Wipe the machine with a damp cloth.

Always wipe the knives of the cutting tools

dry after use.

Always store the cutting tools (2) on the

hangers (3:A) on the wall.

Never use sharp objects or a high-pressure

spray gun for cleaning.

Never spray water on the sides of the

machine.

CHECK EVERY WEEK

That the machine stops as soon as the pusher

plate (1:A) has been moved up and swung

out, and that it restarts when the pusher

plate has been swung in and lowered.

That the machine cannot be started with the

feed cylinder (1:C) removed and with the

pusher plate lowered.

That the machine cannot be started with the

feed cylinder (1:O) fitted but the feed

hopper (1:N) removed.

Remove the plug from the power supply

socket and then check that the electric cable

is in good condition and is not cracked on

the outside.

If any of the safety functions does not

perform as intended or if the electric cable is

cracked, get a specialist to attend to the

machine before connecting it back to the

power supply.

Check that the pusher plate shaft (1:I) has

been lubricated as necessary and runs freely.

If the shaft does not run freely, clean it

carefully and lubricate it with a few drops of

machine oil.

Check that the knives and shredder plates

are in good condition and are sharp.

TROUBLE-SHOOTING

FAULT: The machine cannot be started, or

stops while it is running and cannot be

restarted.

REMEDY: Check that the plug is securely

fitted into the power supply socket, or that

the isolating switch is closed. Check that the

feed cylinder (1:C) alternatively (1:O),

pusher plate (1:A) or the feed hopper (1:N)

is locked in the correct position. Move down

the pusher plate into the feed cylinder.

Check that the fuses in the fuse box for the

premises have not blown and that they have

the correct rating. Wait for a few minutes

and try to restart the machine. If the machine

still fails to run, call a specialist.

FAULT: Low capacity or poor cutting results.

REMEDY: Make sure that you are using the

correct cutting tool or combination of

cuttings tools (2). Fit the drilling sleeve (1:J)

alternatively the stirring sleeve (1:M). Check

that the knives and shredder plates are in

good condition and are sharp. Press the

food down loosely.

FAULT: The cutting tool (2) cannot be

removed.

REMEDY: Always use the ejector plate (1:D).

Use a thick leather glove or the like that the

knives of the cutting tool cannot cut through,

and turn the cutting tool clockwise to release

it.

FAULT: The drilling sleeve (1:J) alternatively

the stirring sleeve (1:M) cannot be removed.

REMEDY: Use the spanner (1:K) to unscrew

the drilling sleeve (1:J) alternatively the stirring

sleeve (1:M) clockwise.

TECHNICAL SPECIFICATION

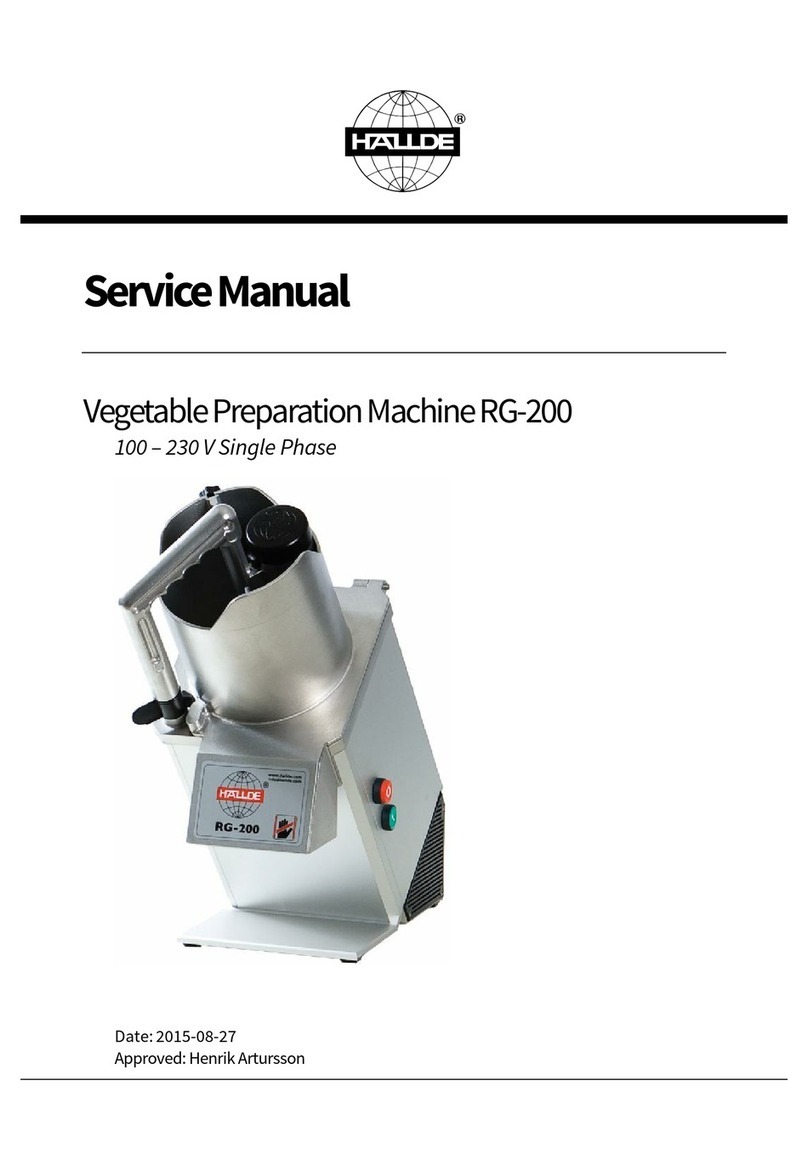

MACHINE: Motor: 0.75 kW, 230 V, single-

phase, 50 Hz, or 400 V, 3-phase, 50 Hz,

with thermal motor protection. Transmission:

gears. Safety system: Four safety switches.

Degree of protection: IP44. Power supply

socket: Earthed, single-phase, 10 A, or 3-

phase, 16 A. Fuse in fuse box for the

premises: 10 A, slow-blow. Sound level LpA

(EN31201): 73 dBA.

TOOLS: Diameter: 215 mm. Speed: 360

rpm.

MATERIALS: Machine housing and feed

cylinder: Anodized or polished aluminium

alloy and/or stainless steel. Cutting tool

discs: Aluminium alloy. Cutting tool knives:

Knife steel of the highest quality.

NET WEIGHTS: Machine base: 26 kg. Feed

cylinder with push feeder: 6 kg. Feed

cylinder with feed hopper: 7,5 kg. Cutting

tools: About 1 kg on average.

STANDARDS: NSF STANDARD 8 for

machine, EU Machine Directive 89/

392EEC.