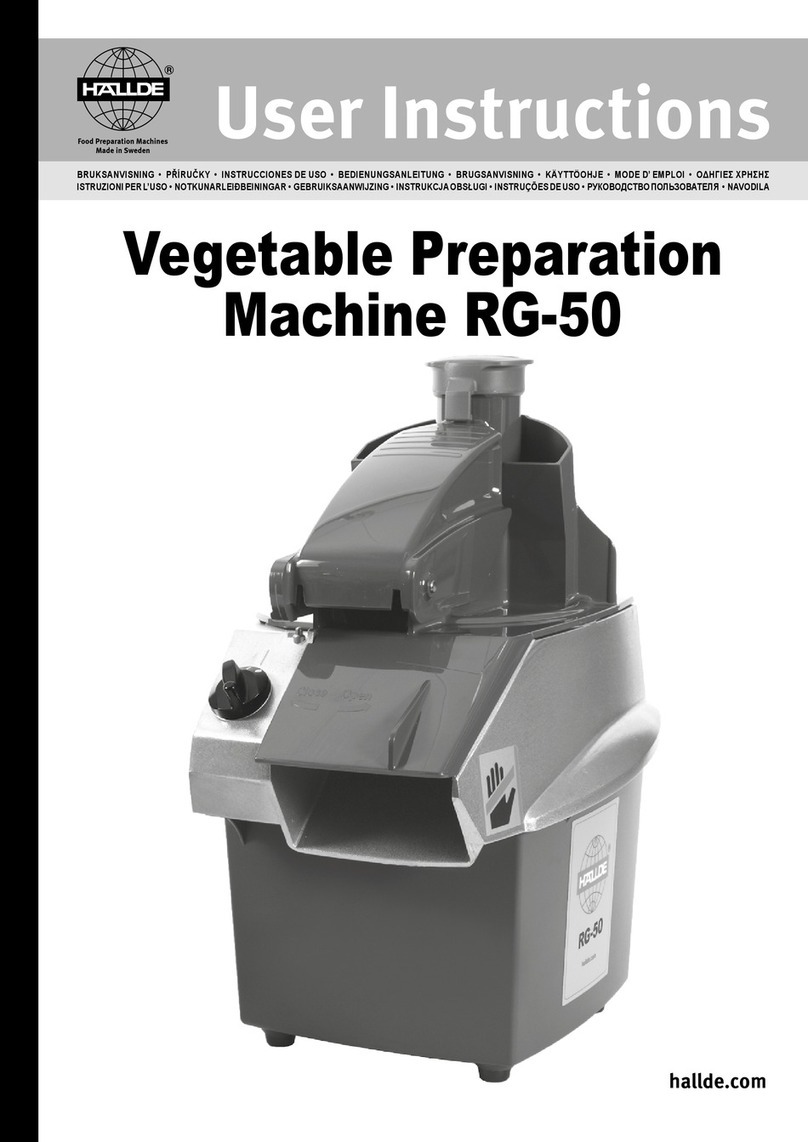

USERINSTRUCTIONS

HALLDERG-50

(GB)

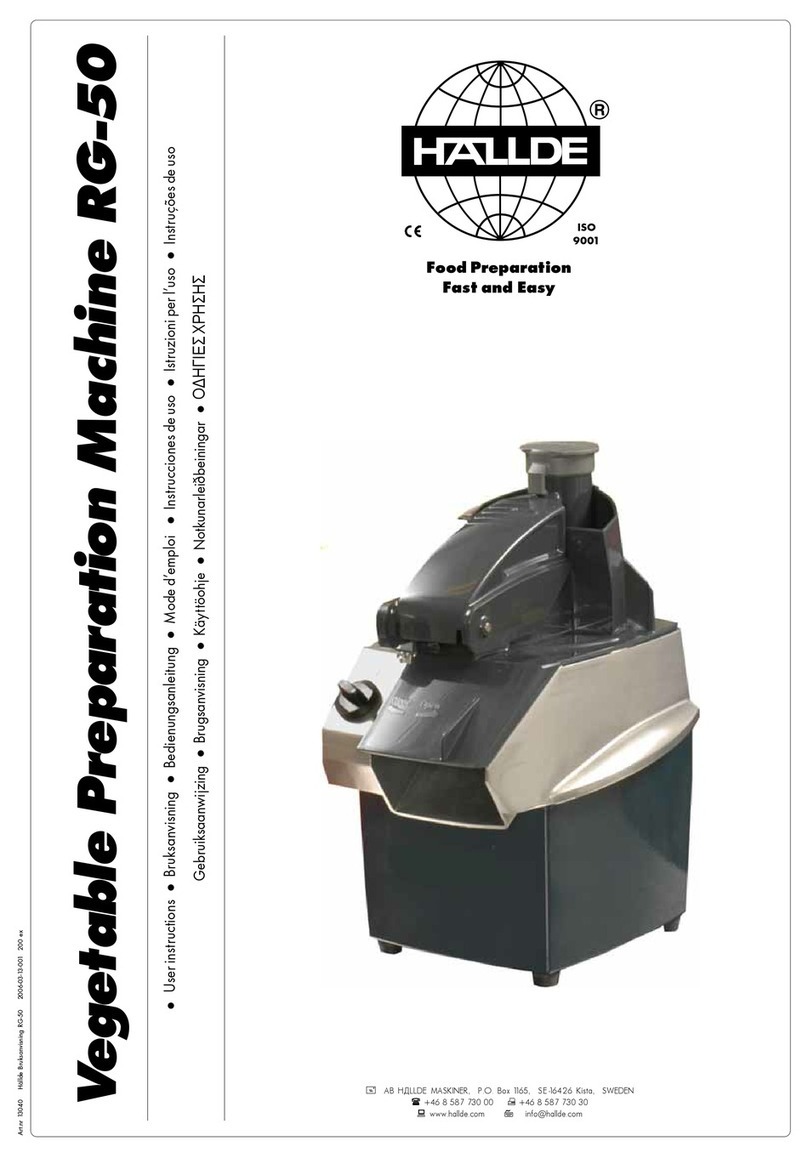

WARNING!

Be very careful, especially of your

hands, with sharp knife bladesand

moving parts.

Alwayscarry the machine by the two

handles(A17) on the sidesof the

machine base.

Never put your handsinto the feed

compartment (A4) or in the feed tube

(A2).

Alwaysuse the pusher (A1) during

cutting with the feed tube (A2)

Before cleaning the machine, always

switch it off by moving the speed

control (A15) into the “O” position and

then removing the power plug from the

wall socket alternatively turn off the

mainsswitch.

Alwaysgrip the feedershandle (A3)

when the feed compartment (A4) is

being opened or closed.

The machine may only be repaired and

the machine base (A16) opened by an

authorized service mechanic.

Unpacking.

Check that all the parts are included, that the

machine works and that nothing has been

damaged during shipping. Claims sho uld be

made to the machine supplier within eight days

of delivery.

Installation.

Co nnect the machine to a mains electricity

supply with specification in acco rdance with the

details on the data plate o n the back of the

machine base (A16 ). Place the machine on a

sturdy bench or table 650 - 900 mm high.

Safety check before processing.

Remove the feeder (A5 ), any cutting tools (A6 -

A12) and the ejecto r plate (A13) in accordance

with the instructio ns under the heading “Remo-

ving the feeder”, and then check that the

machine will not start when the speed co ntro l

(A15) is in the “I” po sition.

Place the feeder (A5 ) o n the machine base

(A16 ) with the text “Close O pen” at 5 o’clock

in relatio n to the outlet o f the machine base

(D1 ) and press the feeder clockwise as far as it

will go and is firmly in positio n (D2).

Then check that the machine sto ps when the

feeders handle (A3 ) is raised and re-starts

when the feeders handle is lowered, with the

speed co ntrol in position ”I”.

Set the speed co ntro l to position ”I” and then

lift the feeders handle and check that the shaft

(A14) then stops ro tating within two seco nds.

In the event of any fault o r malfunction, call in a

service mechanic to co rrect the fault before

using the machine.

The feeder (A5).

The feeder is used to gether with a suitable

cutting to ol (A6 - A12 ) fo r slicing, dicing,

shredding, grating o f fruit, vegetables, dry

bread, cheese, nuts and/ o r mushro o ms.

The large feed co mpartment (A4) is used

mainly fo r feeding po tatoes, onions, etc. and

cutting larger foods such as cabbage.

The large feed compartment is also used when

the fo o ds has to be cut/ sliced in a specific

direction, e.g. when slicing to mato es and

lemons.

The feed tube (A2 ) is mainly used in co nnection

with processing elongated foo ds such as

cucumber.

Choice of cutting tools(A7 -A12).

• Standard Slicer (10 mm) Slices firm pro ducts

such as ro ot vegetables. • Crimping Slicer (4 ,5

mm) For ripple slicing o f beetroot, cucumber,

carrot, etc. • Fine Cut Slicer (1 , 1 .5 , 2 , 4 , 6 ,

15 mm) Slices firm and so ft pro ducts such as

ro o t vegetables, onio ns, leeks, cucumber, bell

peppers, to mato es, apples, citrus fruits, bananas

and mushro o ms. Shreds Chinese lettuce and

lettuce. 1 mm for Parmesan-flakes. • Julienne

Cutter (2x2 , 2 .5 x2 .5 , 4 .5 x4.5, 10 x10 mm)

Fo r soups, cucumber, salads, etc.2 x2 mm for

julienne po tato es and carro ts. • Dicing G rid

(10 x10 , 15 x15 mm). Dices in co mbination with

the 10 mm standard slicer. Dices ro o t

vegetables, fruit, po tatoes, cabbage, swedes,

carrots, cucumbers, apples, etc. • Soft Dicing

Set (10 x10 x10 , 12.5 x12 .5 x12.5 mm) Dicing

sets incl. two cutting too ls fo r gentle dicing of

to mato es and other so ft, fragile and/ o r juicy

pro ducts. • Raw Fo od G rater/ Shredder (1 .5 ,

2, 3, 4.5, 6, 8, 10 mm) G rates carrots and

cabbage for raw salad. G rates almonds and

o ther nuts, and dry bread. 4 .5 , 6 and 8 mm

are usual for shredding cheese for pizzas,

gratin, etc. 8 and 10 mm is commonly used for

shredding cabbage/ white cabage. • Fine

G rate r (Fine, Extra Fine) Fine versio n grates

po tatoes for potato pancakes, hard/ dry

cheeses such as Parmesan fo r pasta, dry bread,

ho rseradish. Extra fine version grates black

radish, dry bread.

Removing the feeder (A5).

Turn the feeder anti-clockwise as far as it will go

(C), then lift off the feeder.

Turn the cutting to o l (A6, 7 , 8 , 9 , 11 o r 12)

clockwise and lift itoff.

If you have been using a dicing grid (A10 ) lift it

off.

Lift o ff the ejecto r plate (A13).

Fitting the feeder (A5).

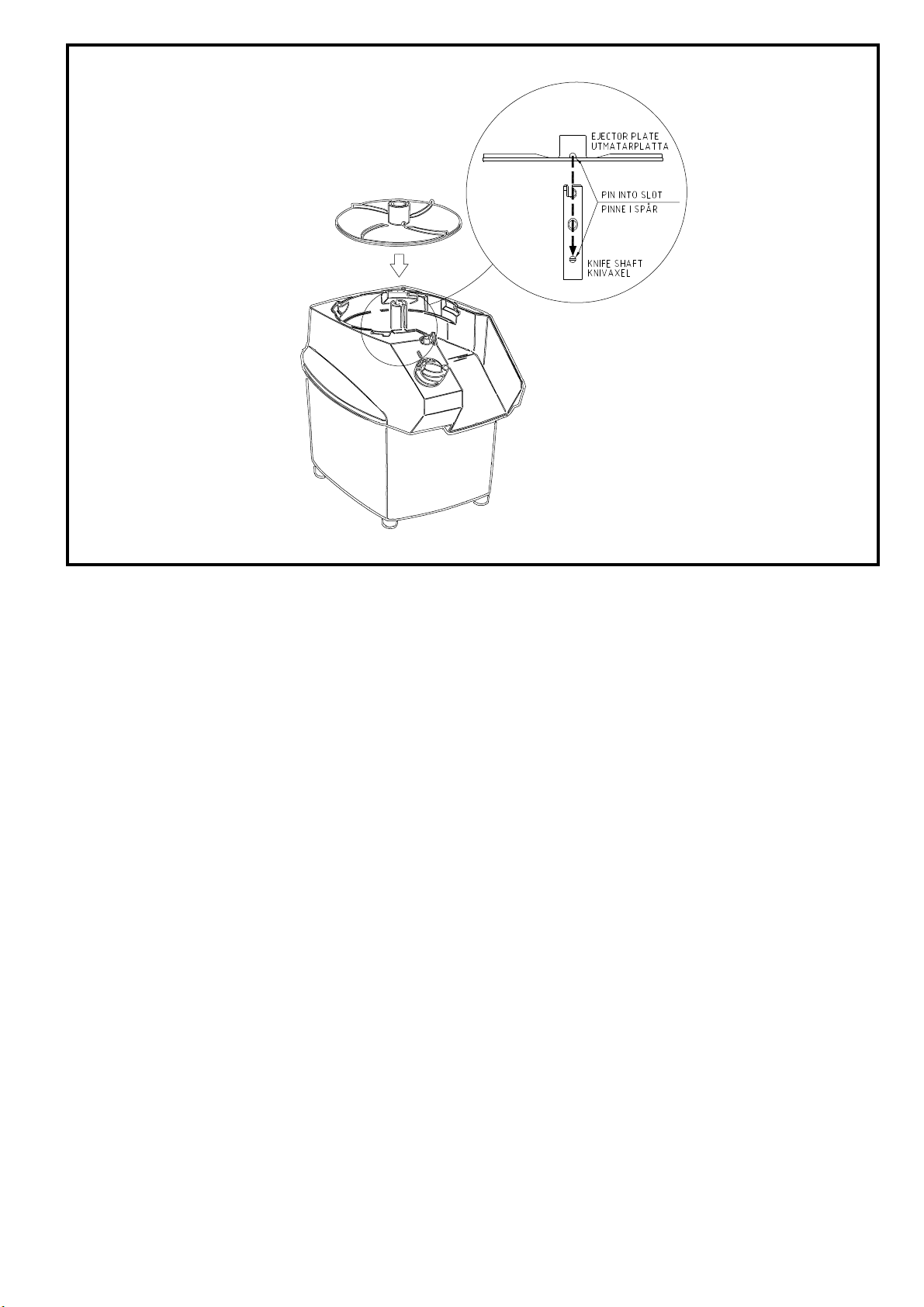

Place the ejector plate (A13) on the shaft (A14 )

and turn/ press do wn the ejector plate into its

co upling (B1).

During dicing: place the dicing grid (A10 ) with

the sharp edge of the knives upward, so that

the recess in the side o f the dicing grid fits into

the guide grove on the machine base (B2).

Then place the standard slicer so that it dro ps

down into its co upling (B3).

During slicing, shredding and grating: place

only the chosen cutting to o l (A6, 7 , 8 , 9 , 11 or

12) on the shaft and rotate the cutting to o l so

that it drops into its co upling.

Place the feeder (A5) on the machine base

(A16) so that the text “Close O pen” is at 5

o’clock in relation to the o utlet o f the machine

base (D1 ) and turn the feeder clockwise as far

as it will go and it is firmly in po sitio n (D2).

Using the speed control (A15).

W ith the speed co ntrol (A15) in the ”O ” po si-

tio n the machine is switched off. In the ”I” po si-

tio n the machine o perates co ntinuo usly.

Cleaning.

Always clean the machine thoro ughly

immediately after use.

First switch o f the machine by setting the speed

co ntrol (A15) to the “O ” po sitio n and then

remo ve the power supply plug from the wall

socket alternatively turn o ff the mains switch.

Take all remo vable parts o ff of the machine

base (A16 ) and clean and dry them

thoro ughly.

Never wash light metal items in the dishwasher

unless they are marked “diwash”.

If the cutting to o ls are marked "diwash", read

and follo w the special "diwash" user instruction

manual carefully.

Rinse the machine housing fro m above (never

fro m the side) and/ or whipe it with a damp

cloth.

Never use sharp objects, sco uring po wder o r

pads, o r high pressure hoses.

Never leave the cutting tools (A6-A12 ) in a wet

co ndition when they are not being used.

Perform the following checksweekly.

Remove first the feeder (A5), any cutting to o ls

(A6-A12) and the ejector plate (A13).

Turn the speed co ntro l (A15 ) to the “I” po sition

and check that the machine will not start.

Fit the feeder (A5), set the speed co ntro l to the

“I” position and then check that the machine

stops when the feeders handle (A3 ) is raised

and re-starts when the handle is lowered.