5

HALLDE • User Instructions

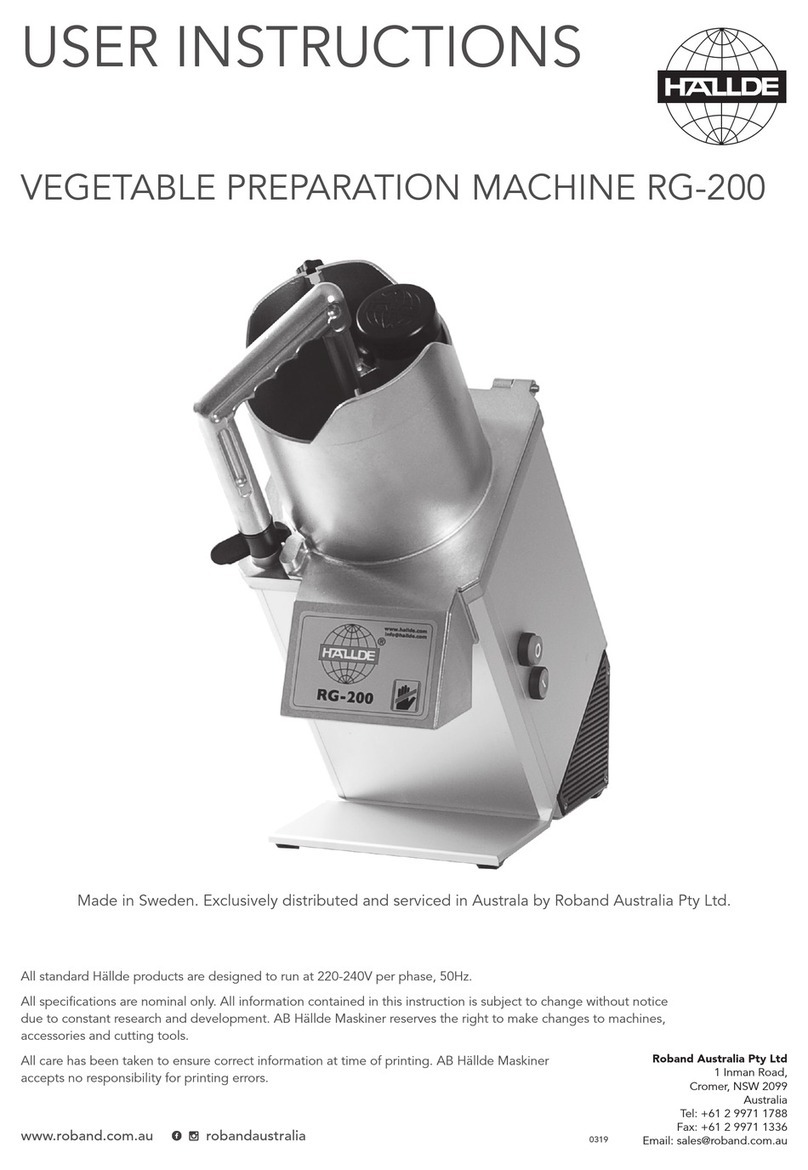

USER INSTRUCTIONS

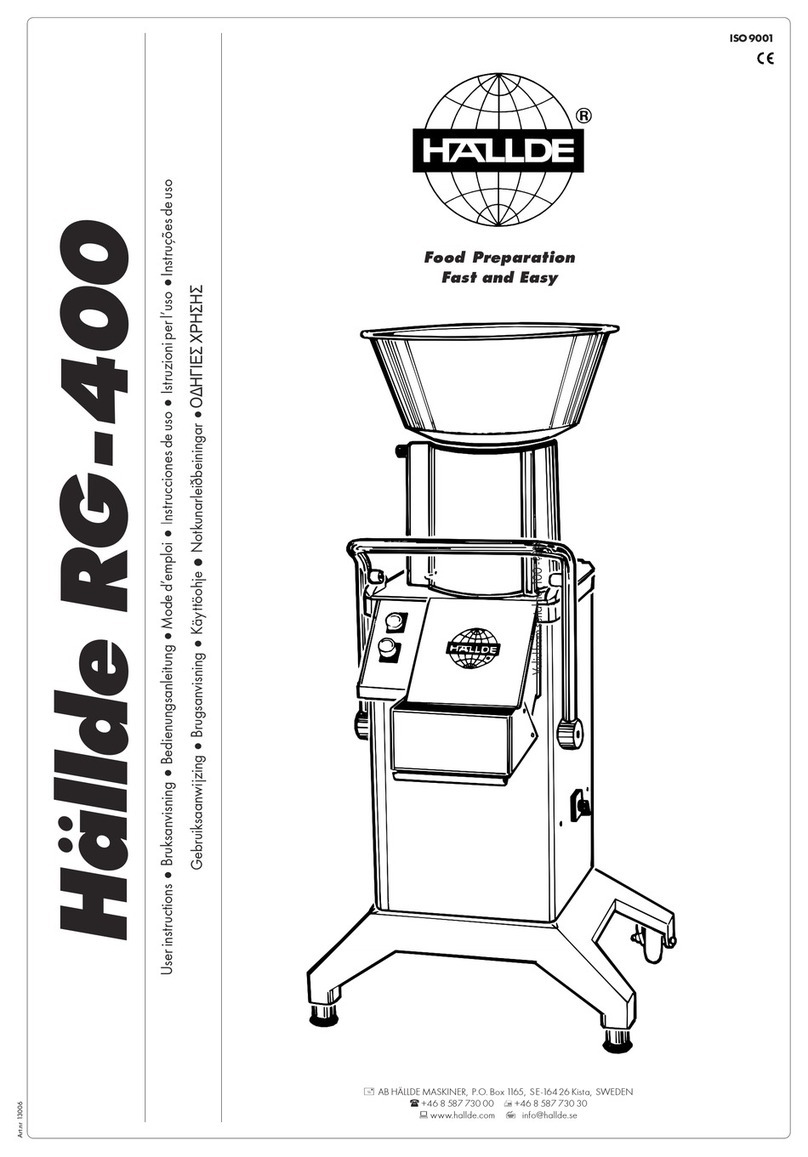

HÄLLDE RG-7

(GB)

CAUTION

Take great care not to injure your hands on

sharp blades and moving parts.

Never put your hands into the exi-feeder

(6:F).

Never put your hands into the outlet of the

machine.

The machine may be installed only by an

authorized specialist.

Only an authorized specialist should be

allowed to repair the machine and open

the machine housing.

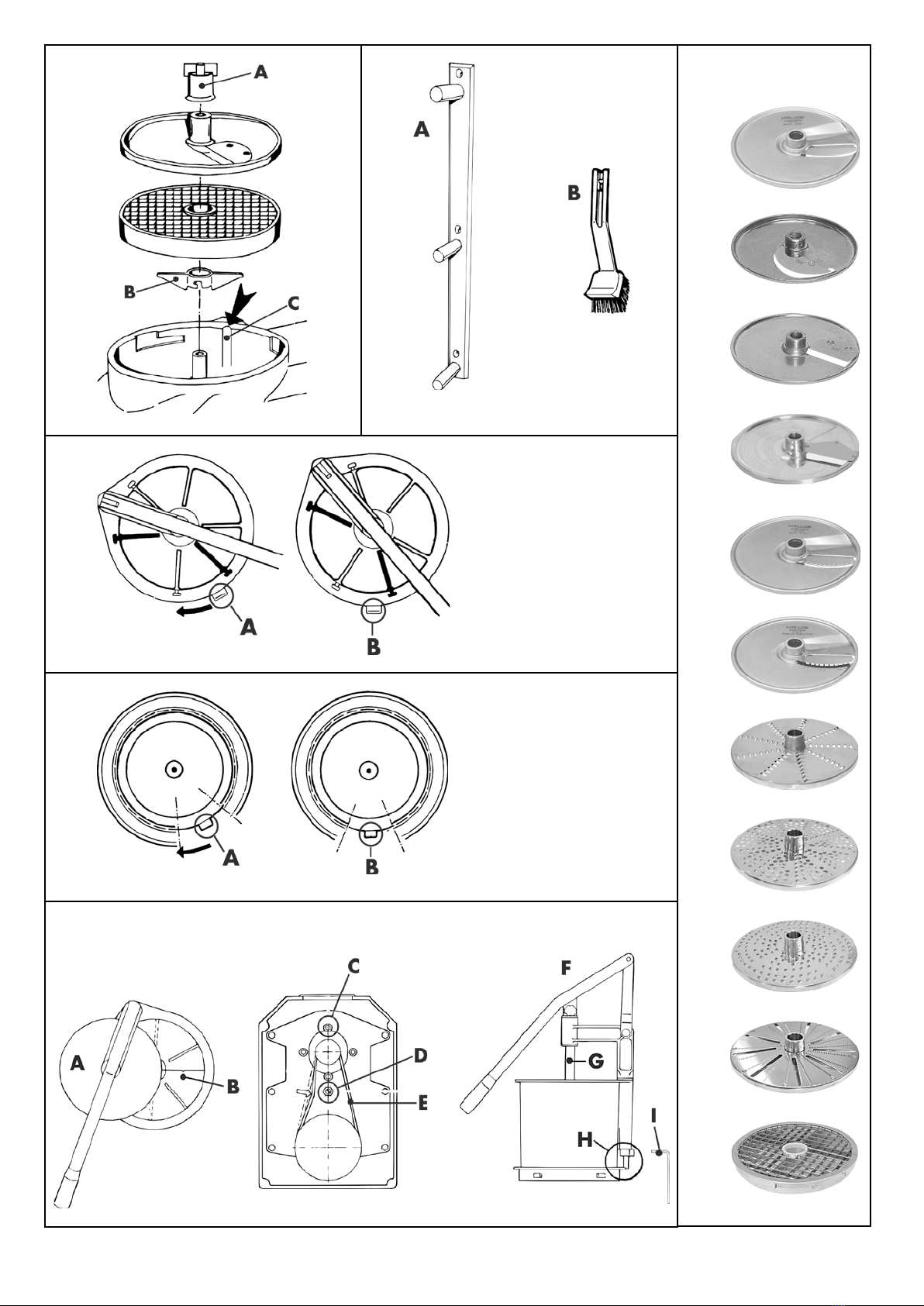

Remove the locking cap (1:A) by turning it

clockwise.

Always press the red stop button of the

machine before tting or removing any

cutting tools, feeder, etc., even if the

machine is not running.

This appliance is not to be operated by

children or persons with reduced physical,

sensory or mental capabilities or persons

lacking experience of such appliances,

unless they are given adequate instruction

or supervision.

UNPACKING

Check that all of the parts have been delivered,

that the machine operates as intended, and

that nothing has been damaged in transit. The

machine supplier should be notied of any

shortcomings within eight days.

INSTALLATION

Connect the machine to an electric power

supply which is suitable for the machine.

The machine should be placed on a countertop

or table which is about 650 mm high.

Locate the hanger (2:A) for the cutting tools

(3) on the wall in the vicinity of the machine

for convenient and safe use.

Check the following three points without

locking cap (1:A), cutting tool (3) and ejector

plate (1:B) tted to the machine.

That the shaft rotates clockwise.

That the machine cannot be started without

the exi-feeder (6:F) tted.

That the machine stops when the feed plunger

(6:A) of the exi-feeder is swung to the side

so that the exi-feeder opening (6:B) is larger

than 45 mm.

If the machine does not perform correctly,

summon a specialist for remedying the fault

before taking the machine into operation.

CHOOSING THE RIGHT

CUTTING TOOLS

SLICER (3:A): Slices hard and soft vege-

tab les, fruits, mushrooms etc. Dices when

combined with a suitable Dicing Grid.

Cut French fries in combination with Potato

Chip Grid.

FINE CUT SLICER (3:B): Slices hard and soft

vegetables, fruits, mushrooms etc. Dices when

combined with a suitable Dicing Grid.

STANDARD SLICER (3:C): Slice hard/

rm products, such as root vegetables etc.

Dice when combined with a suitable Dicing

Grid.

SOFT SLICER (3:D): Slices soft vegetables,

fruits, mushrooms etc. Preferably used when

dicing soft products, in combination with a

suitable Dicing Grid.

CRIMPING SLICER (3:E): Cut decorative

rippled slices of beetroot, cucumber, carrots,

etc.

JULIENNE CUTTER (3:F): Cut julienne of rm

products for soups, salads, stews, decorations

etc. Suitable to cut slightly curved potato chips/

French fries.

GRATER/SHREDDER (3:G): Grates carrots

and cabbage for raw salads. Grates nuts,

almonds and dry bread. Grater 6 or 8 mm is

commonly used for grating cheese for pizza

and when shredding cabbage.

FINE GRATER (3:H): For finely grating

products, from hard/dry cheeses, raw potatoes

for Swedish potato pancakes and bread for

making breadcrumbs.

HARD CHEESE GRATER (3:I): Ideal for grating

hard cheese such as parmesan. Produces

a somewhat coarser grate than the Fine Grater,

Extra ne.

FINE GRATER, EXTRA FINE (3:J): Grates

products very finely, such as black radish

grated for purée and potatoes for mashing.

DICING GRID (3:K): Cut dices in combination

with a suitable type of slicer. Dice both hard and

soft vegetables, fruits etc.

FITTING AND REMOVING

THE CUTTING TOOLS

When tting the tools, place the ejector plate

(1:B) on the shaft and turn/press down the

ejector plate into its coupling.

For dicing or chopping onions, rst place a

suitable dicing grid in the machine with the

screw head on the dicing grid edge in the

groove (1:C) in the machine.

For dicing, then choose a suitable Slicer, Fine

Cut Slicer, Standard Slicer or Soft Slicer and

t the slicer to the shaft and then turn it so that

the slicer drops into its coupling.

For slicing, shredding and grating, t instead

only the selected cutting tool to the shaft and

turn the cutting tool so that it drops into its

coupling.

On cutting with the exi-feeder (6:F), secure

the locking cap (1:A) by turning it anti-clock wise

on the centre shaft of the cutting tool.

To remove, unscrew the locking cap (1:A) by

turning it clockwise and remove the cutting

tool (3) and the ejector plate (1:B).

FITTING AND REMOVING

THE FLEXI-FEEDER

To t the exi-feeder (6:F), place it with the

snap lock at ”5 o’clock” (4:A), viewed from the

machine outlet.

Then turn the exi-feeder clockwise to the

locked position at ”6 o’clock” (4:B).

To remove, bend the snap lock (4:B) up slightly,

at the same time turning the exi-feeder anti-

clockwise.

CLEANING

Switch off the machine and remove the power

supply plug from the socket.

Carefully clean the machine immediately after

use.

All cutting tools can be cleaned in a dishwasher.

If you have used a dicing grid (3:K), leave it

in the machine, and use the brush (2:B) for

pushing out any product remaining in the grid.

Remove the loose parts of the machine, wash

them and dry them thoroughly.

Wipe the machine with a damp cloth.

Always wipe the knives of the cutting tools

dry after use.

Always store the cutting tools (3) on the

hangers (2:A) on the wall.

Never use sharp objects or a high-pressure

spray gun for cleaning.

Never spray water on the sides of the machine.

CHECK EVERY WEEK

Check that the machine stops as soon as the

feed plunger (6:A) of the exi-feeder is moved

to the side so that the exi-feeder opening

(6:B) is larger than 45 mm. If not, the setting

of the stop pad (6:H) must be adjusted by an

authorized specialist. The spanner (6:I) should

be used for releasing/locking the stop pad.

Remove the plug from the power supply socket

or open the isolating switch and then check that

the electric cable is in good condition and is not

cracked on theoutside.

If any of the two safety functions does not

perform as intended or if the electric cable

is cracked, get a specialist to attend to the

machine before connecting it back to the

power supply.

Check that the drive belts (6:E) are tensioned.

See under the heading TENSIONING THE

DRIVE BELTS.