CONTENTS

Form No. UGAM-0908

i

INTRODUCTION

Hatco Ultra-Glo®Ceramic Strip Heaters ensure

maximum food holding and minimize the risk of food-

borne illness. Optimum safety and quality is the result of

food held at the proper serving temperatures using Ultra

Glo’s pre-focused heat patterns. The pre-focused heat

pattern prevents foods from being over-cooked in the

middle and cooling off around the edges by

concentrating higher temperatures to the outer edges of

holding surfaces where heat loss is the greatest. Utilizing

specially designed reflectors to direct the heat from the

element, Ultra-Glo Ceramic Strip Heaters safely maintain

peak serving temperatures longer without cooking the

food beyond the point of excellence. The ceramic

element heat output allows the units to be mounted at

increased heights for improved working clearances.

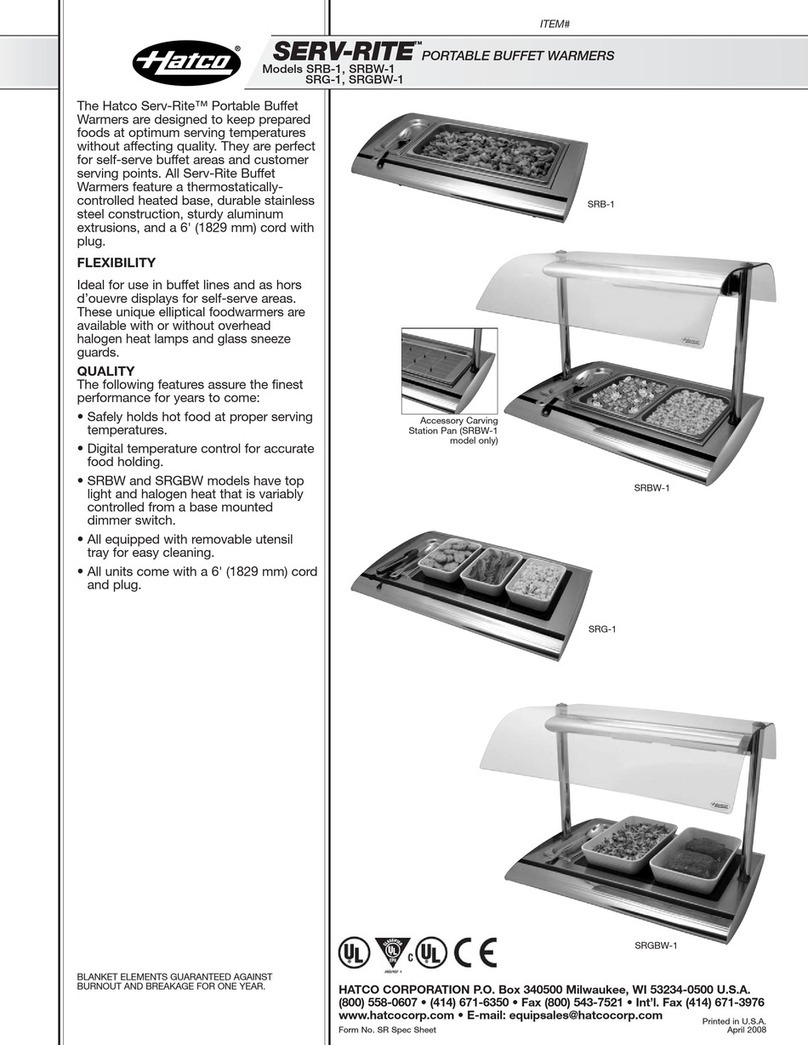

Ultra-Glo Ceramic Strip Heaters are available from the

factory with or without shatter-resistant display lights to

illuminate the warming area. These bulbs have a special

coating that guards against injury and food

contamination in the event of breakage.

Ultra-Glo Ceramic Strip Heaters are a product of

extensive research and field testing. The materials used

were selected for maximum durability, attractive

appearance, and optimum performance. Every unit is

inspected and tested thoroughly prior to shipment.

This manual provides the installation, safety, and

operating instructions for Ultra-Glo Ceramic Strip

Heaters. Hatco recommends all installation, operating,

and safety instructions appearing in this manual be read

prior to installation or operation of the strip heaters.

Safety information that appears in this manual is

identified by the following signal word panels:

WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not related

to personal injury.

Important Owner Information...............................i

Introduction ...........................................................i

Important Safety Information..............................1

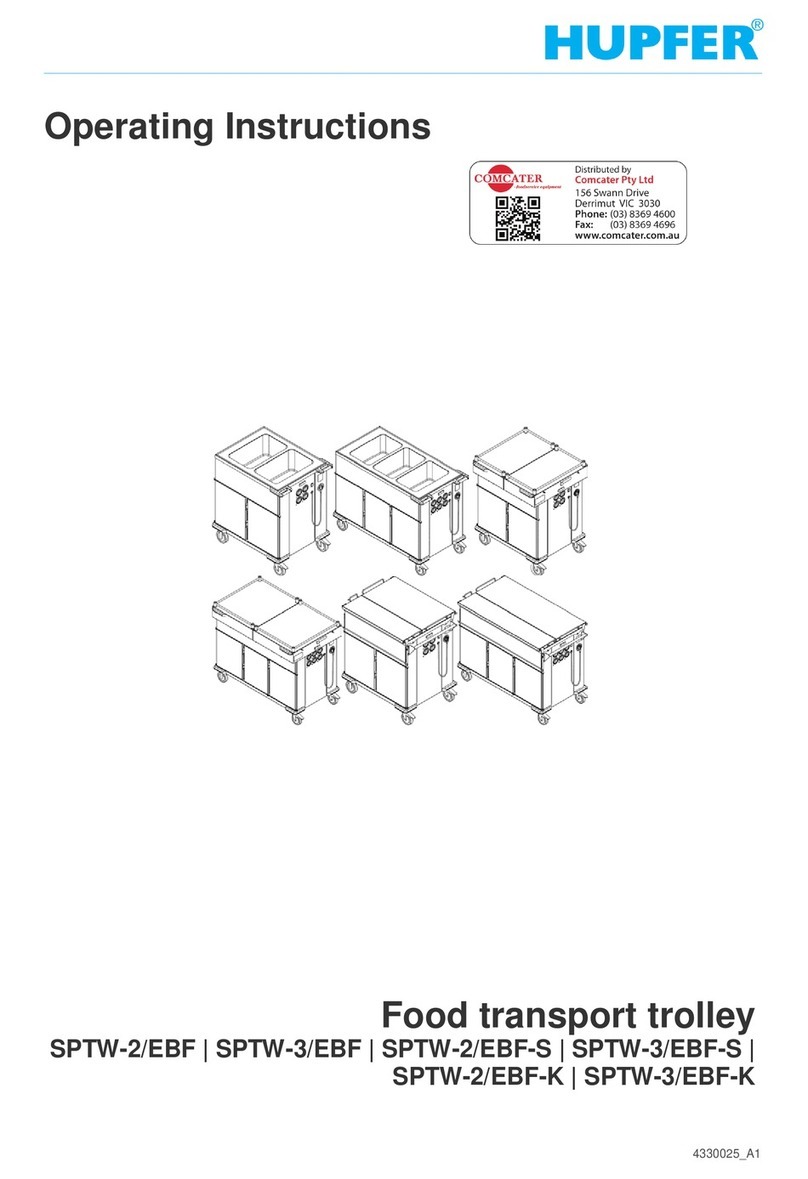

Model Designation ...............................................2

Model Descriptions..............................................2

Specifications.......................................................3

Electrical Rating Charts...................................3

Dimensions ....................................................11

Installation ..........................................................12

General..........................................................12

Minimum Clearance Requirements ...............13

Recommended Mounting Heights .................13

Assembly.......................................................14

Undershelf Mounting .....................................14

Permanent Surface Mount.............................15

Overhead Mounting .......................................16

Electrical Wiring Hook-Up..............................16

Operation ............................................................17

Maintenance .......................................................18

General..........................................................18

Replacing Display Light Bulbs.......................18

Troubleshooting Guide......................................19

Options................................................................20

Hatco Limited Warranty.....................................21

Authorized Parts Distributors...........Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number

(identification decal located on the underside of the

unit), voltage, and purchase date of your strip heater

in the spaces below. Please have this information

available when calling Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.S.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.S.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts and Service)

(414) 671-3976 ( nternational)

24 Hour 7 Day Parts and Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.

Additional information can be found by visiting our web

site at www.hatcocorp.com.