°

Warranty

Warranty malfunctions occurring under conditions of normal use

in conformity with the Instruction Manual and Product Precau-

tionary Markings will be repaired free of charge. This warranty

is valid for a period of one (1) year from the date of purchase.

Please contact the distributor from which you purchased the

product for further information on warranty provisions.

Introduction

Thank you for purchasing the HIOKI Model 9272-05 and 9272-

10 CLAMP ON SENSOR. To obtain maximum performance

from the device, please read this manual first, and keep it handy

for future reference.

Initial Inspection

When you receive the device, inspect it carefully to ensure that

no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evi-

dent, or if it fails to operate according to the specifications, con-

tact your dealer or Hioki representative.

This manual contains information and warnings essential for

safe operation of the device and for maintaining it in safe oper-

ating condition. Before using it, be sure to carefully read the fol-

lowing safety precautions.

Safety Symbols

The following symbols in this manual indicate

tance of cautions and warnings.

Other Symbol

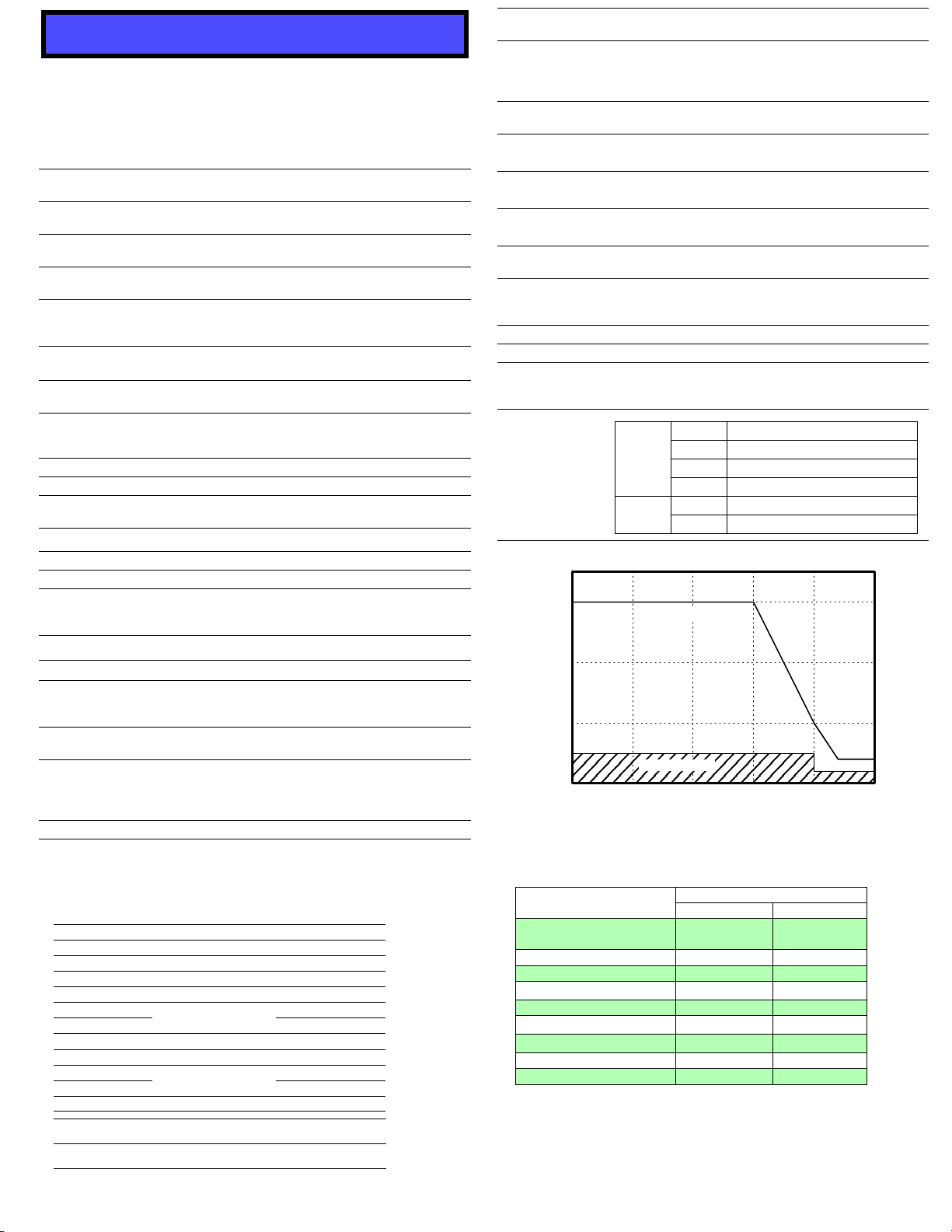

Measurement categories

This device complies with CAT III safety requirements.

To ensure safe operation of measurement devices, IEC 61010 es-

tablishes safety standards for various electrical environments, cat-

egorized as CAT II to CAT IV, and called measurement categories.

CAT II: Primary electrical cir-

cuits in equipment

connected to an AC

electrical outlet by a

power cord (portable

tools, household

appliances, etc.)

CAT II covers directly

measuring electrical

outlet receptacles.

CAT III:Primary electrical circuits of heavy equipment (fixed installa-

tions) connected directly to the distribution panel, and feeders

from the distribution panel to outlets.

CAT IV:The circuit from the service drop to the service entrance, and

to the power meter and primary overcurrent protection device

(distribution panel).

Using a measurement device in an environment designated with a

higher-numbered categorythan thatfor whichthedeviceisrated could

result in a severe accident, and must be carefully avoided.Use of a

measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must

be carefully avoided.

Instrument Installation

Operating temperature and humidity: 0 to 50°C, 80%RH or less (non-condensation)

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

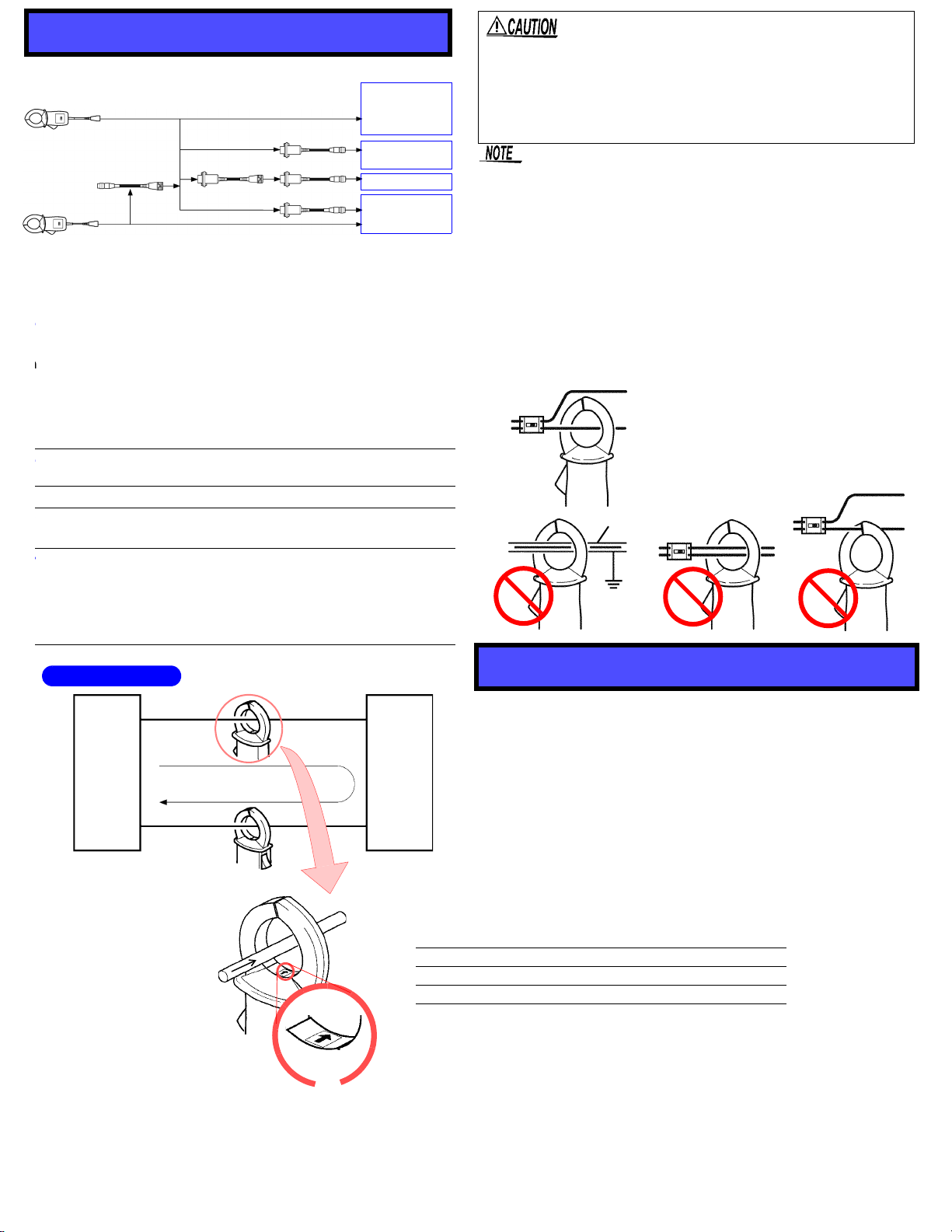

The 9272-05 and 9272-10 was developed for to provide a 20 A,

200 A clamp sensor. Together with the power meter, the 9272-

10 makes it possible to measure alternating current in live pow-

er lines without cutting into the lines.

The sensor features excellent amplitude-frequency response

and phase-frequencyresponse, and is easy to connect anduse.

Its versatility will find application in a wide variety of fields deal-

ing with current and power measurement.

9705 Conversion Cable*1, 9318 Conversion Cable*1,

CT9900 Conversion Cable*1, CT9901 Conversion Cable*2

The Conversion Cable makes it possible to connect to and use

with products that cannot be directly connected to the 9272-05

or 9272-10. (Refer to “Connection example”) (No figures are

added to the accuracy.)

CT9902 Extension Cable

*2

(5 m), CT9903 Extension Cable

*1

(5 m)

• Single sensor cable, 5 m extension (max. 10 m extension)

• Up to two extension cable is connectable. (If three or more-

extension cables are connected to the device, its perfor-

mance is not guaranteed)

• Add the following values to each of the accuracy per cable:

Amplitude accuracy: ±0.1% rdg. (DC f*3 1 kHz)

±0.5% rdg. (1 kHz < f*3)

Phase accuracy: ±(0.1 × f*3 kHz)° (1 kHz <f*3)

*1: For 9272-10, *2: For 9272-05, *3: frequency

Inspection and Maintenance

Pack the device so that it will not sustain damage during ship-

ping, and include a description of existing damage. We cannot

accept responsibility for damage incurred during shipping.

Safety

9272-05

9272-10

CLAMP ON SENSOR

Instruction Manual

Feb. 2017 Revised edition 5

Printed in Japan

9272C981-05 17-02H

EN

• This device is designed

61010 Safety Standards, and has been

oughly tested for safety prior to shipment.

However, mishandling during use coul

in injury or death, as well as damage

device. Be certain that you underst

instructions and precautions in th

before use. We disclaim any responsibility

accidents or injuries not resulting directly

device defects.

• To avoid short circuits and potentially

threatening hazards, never attach the

to a circuit that operates at more than 600V

Indicates cautions and hazards. When the symbol is

printed on the product refer to a corresponding to

Instruction Manual.

Indicates that the device may be connected to

nected from a live circuit.

Indicates a double-insulated device.

Indicates AC (Alternating Current).

Indicates that incorrect operation presents an

hazard that could result in serious injury or

user.

Indicates that incorrect operation presents a

hazard that could result in serious injury or

user.

Indicates that incorrect operation presents a

of injury to the user or damage to the device.

Indicates advisory items related to pe

rect operation of the device.

Indicates a prohibited action.

Avoid the following locations that could cause an accident or dam-

age to the device.

Exposed to direct

sunlight

Exposed to high temper-

ature

In the presence of

corrosive or explosive

gases

Exposed to liquids

Exposed to high humid-

ity or condensation

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Exposed to high levels

of particulate dust Subject to vibration

• Clamp sensor should only be connected to the sec-

ondary side of a breaker, so the breaker can prevent

an accident if a short circuit occurs. Connections

should never be made to the primary side of a breaker,

because unrestricted current flow could cause a seri-

ous accident if a short circuit occurs.

• To avoid electric shock, short circuits and damage to

the device, observe the following precautions:

Check the position of the range switch before taking

measurements.

Disconnect the conductor from the measurement

object before switching ranges.

• To avoid electric shock, do not touch the portion

beyond the protective barrier during use.

• Do not allow the device to get wet, and do not take

measurements with wet hands. This may cause an

electric shock.

• To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

• Before using the device, make sure that the insulation

on the probes is undamaged and that no bare conduc-

tors are improperly exposed. Using the device in such

conditions could cause an electric shock, so contact

your dealer or Hioki representative for repair.

• Note that the device may be damaged if current exceeding the

selected measurement range is applied for a long time.

•When the digital power meter or the clamp unit’s power is turned

off, do not apply current to the clamp sensor. Doing so may

damage the device.

•When disconnecting the connector, be sure to release the lock before

pulling off the connector. Forcibly pulling the con-nector without

releasing the lock, or pulling on the cable, can damage the connector.

•

•

To prevent damage to the connected instruments and the sensor,

never connect or disconnect a sensor while the pow-er is on, or while the

sensor is clamped around a conductor. Toavoid damage tothe device,

protect it from physicalshock when transporting and handling. Be

especially careful to avoid physical shock from dropping.

• Do not store or use the device where it could be exposed to di-rect sunlight,

high temperature or humidity, or condensation. Under such conditions, the

device may be damaged and insu-lation may deteriorate so that it no longer

meets specifications.

• Measurements are degraded by dirt on the mating surfaces

of the jaws so keep the surfaces clean by gently wiping with

a soft cloth.

• To avoid breaking the cables, do not bend or pull them.

• Avoid stepping on or pinching cables, which could damage

the cable insulation.

• Keep the cables well away from heat sources, as bare con-

ductors could be exposed if the insulation melts.

• Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and high-

current conductors, or in the presence of strong electromag-

netic fields such as near radio transmitters.

• This device may cause interference if used in residential areas.

Such use must be avoided unless the user takes special mea-

sures to reduce electromagnetic emissions to prevent interfer-

ence to the reception of radio and television broadcasts.

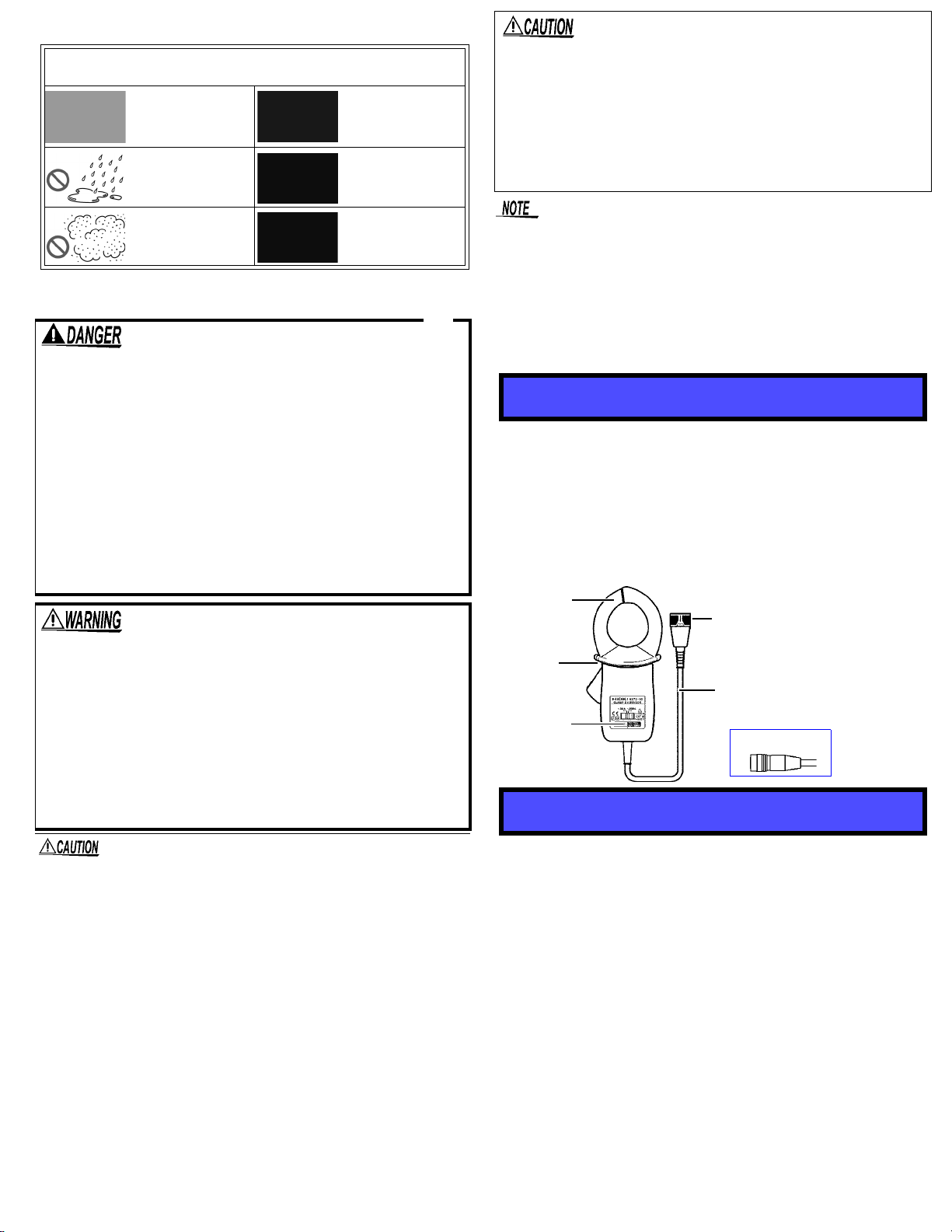

Overview

Options

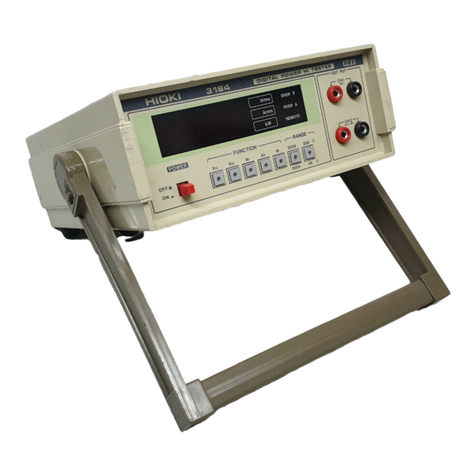

Jaws

Cable

Range switch

Barrier

Output connector

9272-05

Output connector

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com