(Accuracy guaranteed for one year at 23°C±5°C(73°F±9°F), 80%RH or less.

Endurance number of the jaw opening and closing part: 10000 times)

f.s. : maximum display value or scale length

rdg.: reading value (The value currently being measured and indicated on the

measuring product)

Follow these precautions to ensure safe operation and to obtain the

full benefits of the various functions.

Measurement categories

This productconforms tothe safety requirements for CAT III measurement

products.

Toensure safe operation of measurement products, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II

toCAT IV,and called measurement categories.

CAT II: Primary electrical circuits

in equipment connected to an AC

electrical outlet by a power cord

(portable tools, household appli-

ances, etc.)

CAT IIcoversdirectly measuring

electrical outlet receptacles. CAT

III: Primary electrical cir-cuits

of heavy equipment (fixed

installations) connected directly

to the distribution panel, and

feeders from the distribution panel to outlets.

CAT IV: The circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

Using a measurement product in an environment designated with a higher-

numbered category than that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II toCATIV

measurement applications could result in a severe accident, and must be care-

fully avoided.

Specifications

Rated primary current 9695-02: 50 A AC, 9695-03: 100 A AC

Output voltage 9695-02: 10 mV AC/A, 9695-03: 1 mV AC/A

Amplitude accuracy

±

0.3% rdg.±0.02%f.s. (f.s.:50 A (

9695-02

)/

100 A (9695-03)

,

45Hz to 66Hz, at jaw center)

Phase accuracy 9695-02: Within

±

2° (45 Hz to 5 kHz)

9695-03: Within

±

1° (45 Hz to 5 kHz)

Amplitude frequency

characteristics Within ±1% at 40 Hz to 5 kHz (deviation from accuracy)

Effect of conductor

position Within ±0.5% (deviation from center)

Effect of external

electromagnetic field 0.1 A equivalent or lower

(in an AC electromagnetic field of 400 A/m)

Maximum permissible

input 60 A continuous (

9695-02)/

130 A continuous (

9695-03

)

(at 45 to 66 Hz, ambient temperature 50

°

C

)

Temperature coefficient 0.02%rdg./

°

C

Dielectric strength

3536

V ACrms for 15 sec (between electric circuit and jaw)

Maximum rated voltage to

earth 300 V ACrms or lower (Insulated conductor)

Operating Temperature

&Humidity 0 to 50

°C (32 to 122°F)

, 80%RH or lower

(non-condensating)

Storage Temperature

&Humidity -10 to 60

°C(14 to 140°F)

, 80%RH or lower

(non-condensating)

Operating Environment Indoors, up to 2000 m (6562-ft.) ASL

Standards applying Safety

EN61010

Measurement Category III, Pollution Degree 2

(Anticipated Transient Overvoltage: 4000 V)

EMC EN61326

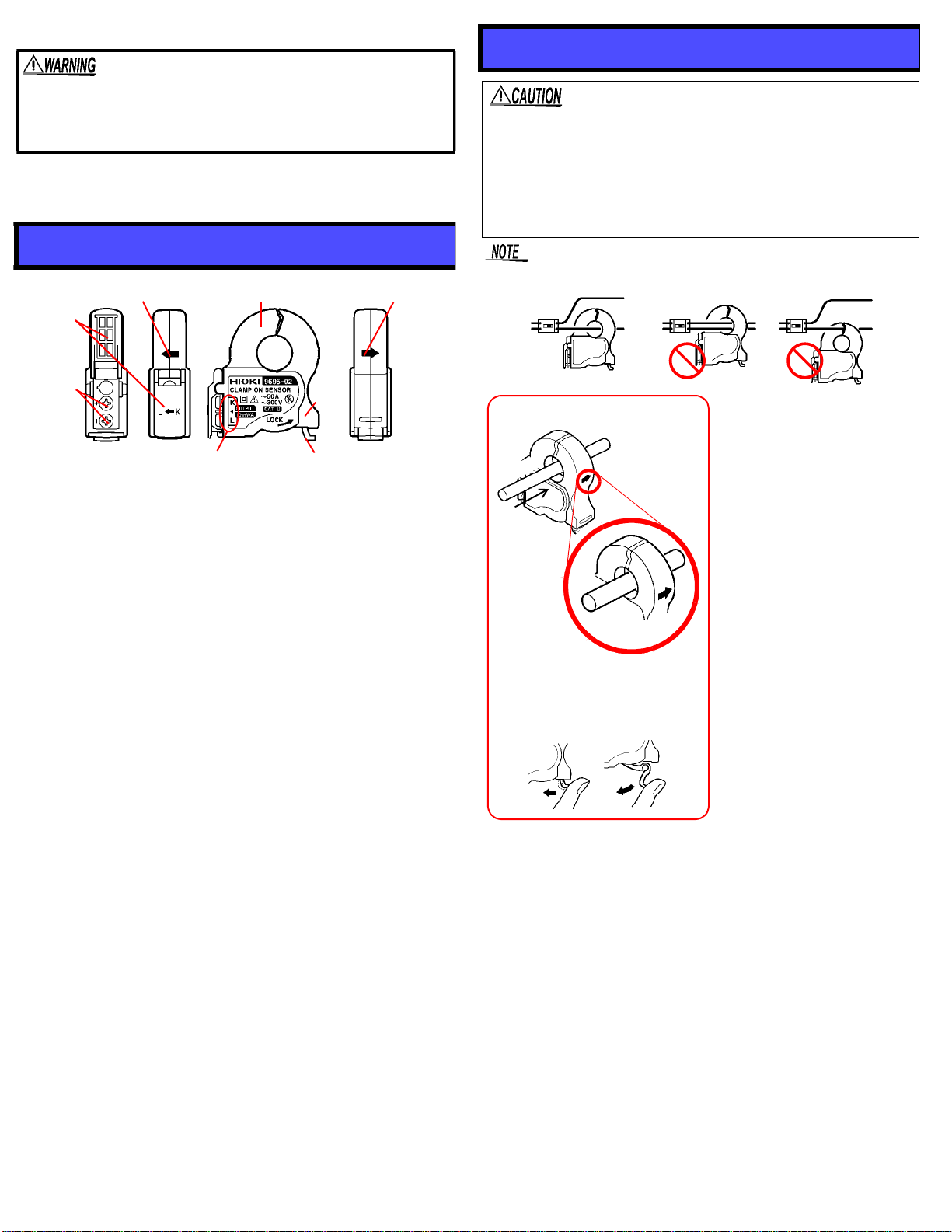

Measurable conductor

diameter 15 mm (0.59”) or less

Output terminals M3 terminal (Maximum outside diameter: 6.5 mm/0.26”, inside

diameter: 3.2 mm/0.13”)

Cable length 3 m or less

Dimensions Approx. 50.5W x 58.0H x 18.7D mm (1.99”W x 2.28”H x

0.74”D) (excluding protrusions)

Mass Approx. 50 g (1.8 oz.)

Accessory Instruction Manual

Option 9219 CONNECTION CABLE, 9238 CLAMP SENSOR CABLE

Safety

This product is designed to conform to IEC 61010 Safety Stan-

dards, and has been thoroughly tested for safety prior to ship-

ment. However, mishandling during use could result in injury or

death, as well as damage to the product. Be certain that you

understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or inju-

ries not resulting directly from product defects.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com