i

Out-of-range indication ...............................39

3.8 Basic Measurement Examples......... 40

4 Applied Measurement 43

4.1 Starting Measurement After

Measured Value Becomes Stable

(Delay Function)............................... 43

4.2 Reducing Variation in Measured

Values (Average Function)............... 44

4.3 Changing Measurement Starting

Conditions (Trigger Function)........... 46

Setting the trigger mode .............................46

Inputting an external trigger ........................46

4.4 Maintaining Measurement

Accuracy (Self-Calibration Function) 47

4.5 Contact Check (Various Settings) .... 49

4.6 Canceling Capacitance of

Measurement Fixture

(Fixture Capacitance Open

Correction Function)......................... 52

4.7 Contact Check (Executing Contact

Check,Setting Reference Value) ..... 53

4.8 Setting Resistivity Calculation

(Resistivity Measurement Function). 55

4.9 Further Accelerating Measurement

(Function of Updating Drawing

During Measurement) ...................... 58

5 Measurement Methods

Suitable for Various

Objects to Be Measured 59

5.1 Measuring Components of Circuits .. 59

Measurement with use of a

measurement xture ...................................60

Measurement without use of a

measurement xture ...................................61

Automatic measurement.............................62

5.2 Measuring Flat Sample .................... 63

Measurement using pin type terminals .......63

Measurement using an electrode for

measuring surface resistance.....................63

Measurement using an electrode for a

at sample ..................................................64

Volume resistance measurement and

surface resistivity measurement

(the functional role of the guard electrode) .64

5.3 Measuring a Liquid Sample.............. 66

When using an electrode for liquid

samples ......................................................66

5.4 Measurement With Use of

Shielding Box ................................... 67

Contents

Introduction.................................................. 1

Notati ........................................................... 1

Verifying Package Contents ........................ 3

Measurement Procedure............................. 6

Safety Information ....................................... 7

Operating Precautions................................. 8

1 Overview 15

1.1 Product Overview and Features....... 15

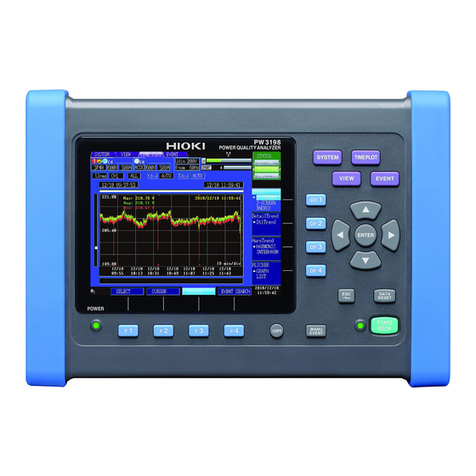

1.2 Names and Functions of Parts......... 16

1.3 Screen Conguration and Operation 21

Measurement screens ................................21

Settings screens .........................................22

1.4 Basic Key Operation ........................ 23

Displaying measurement screen ................23

Displaying the various menu settings

screens .......................................................23

Selecting settings items ..............................24

Methods for changing numerical values .....25

2 Preparing for

Measurement 27

2.1 Connecting Power Cord to

Instrument ........................................ 27

2.2 Connecting Measurement Leads

to Instrument .................................... 28

2.3 Connecting Electrode....................... 28

2.4 Connecting Humidity Sensor............ 29

2.5 Outputting Measurement Current

Value Converted to Analog Signal.... 30

2.6 Turning On/Off Instrument................ 31

2.7 Inspection Before Use...................... 32

3 Basic Measurement 33

3.1 Setting Measured Value Display

Mode ................................................ 33

Changing display notation ..........................34

Changing displayed digits...........................34

3.2 Setting Voltage Value for

Resistance Calculation..................... 35

3.3 Setting Measurement Speed............ 36

3.4 Changing Current Range ................. 37

3.5 Connecting Measurement Leads

or Electrode to Object to Be

Measured ......................................... 38

3.6 Starting/Stopping Measurement....... 39

3.7 Conrming Measurement Results.... 39

Detecting a measurement abnormality .......39

Temperature measurement indication ........39

SM7420A961-02

4

3

2

1

5