2

Verifying Package Contents

Verifying Package Contents

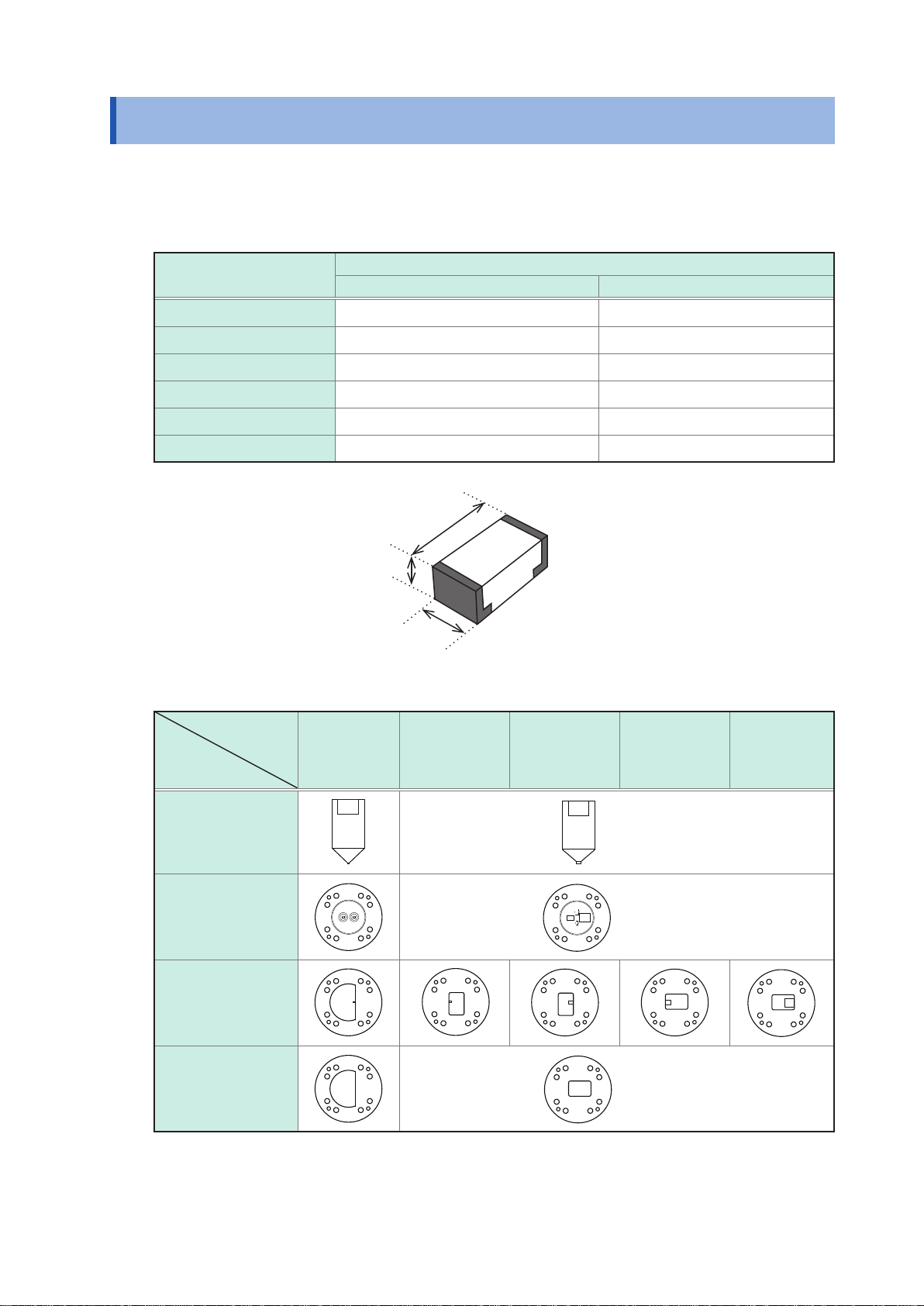

When you receive the device, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories. If damage is evident, or if it fails to operate according

to the specications, contact your authorized Hioki distributor or reseller.

Conrm that the following items are provided.

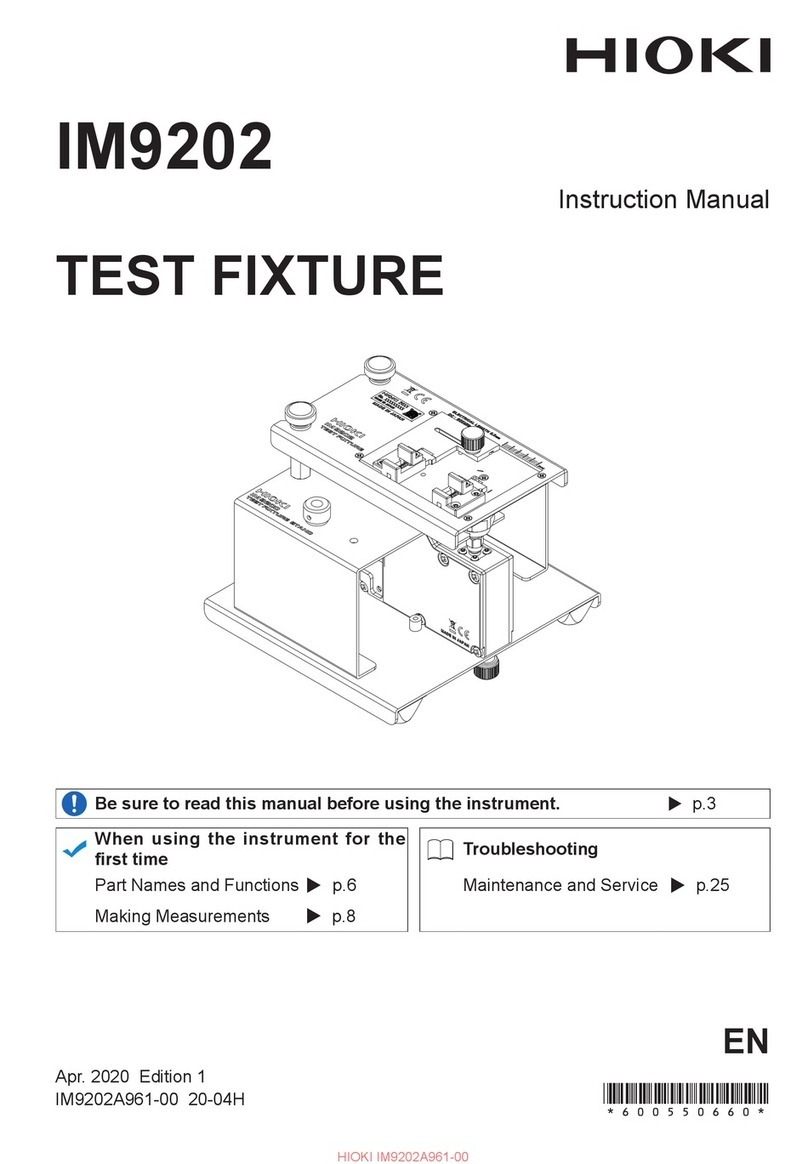

(1)

(3) (4)

(5) (11)(2)

(9)(8)(10)(7)

(6)

Model IM9201 SMD Test Fixture × 1..............................................................................(1)

Short plate × 5................................................................................................................

GND plate × 1

Device guide × 1

(2)

Hexagon socket head bolts (spare, M1.4 × 4 mm) × 4...................................................

Knob (for xing tip pin) × 1

Tip pin × 2

(3)

Brush for cleaning × 1 ....................................................................................................(4)

Hex driver × 1.................................................................................................................(5)

Carrying case × 1...........................................................................................................(6)

Instruction Manual × 1

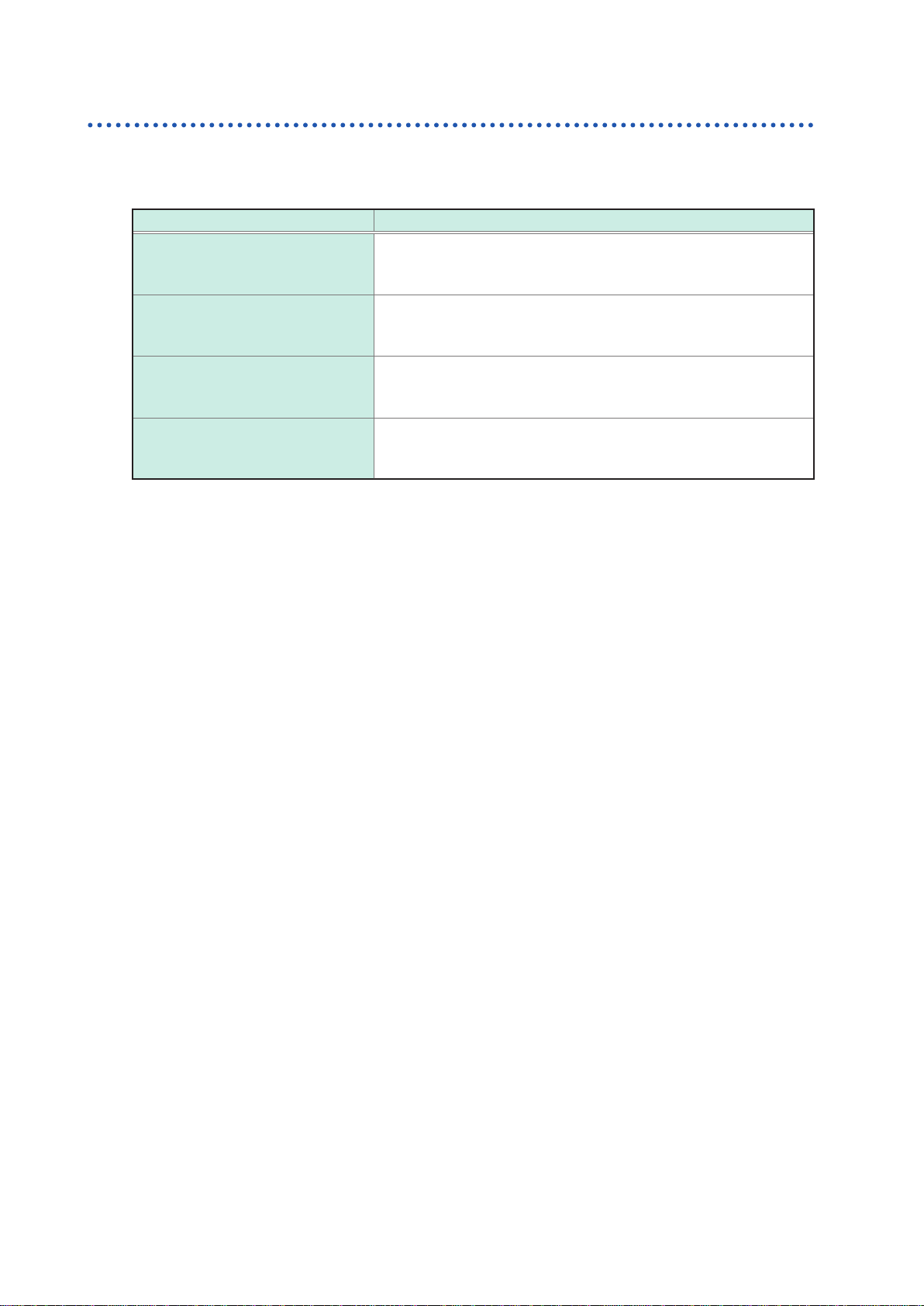

GND plate and device guide for the sizes 1005 (0402), 1608 (0603), 2012 (0805), 3216 (1206), 3225 (1210)

are installed in the device. Refer to "Tip pins, device guides, and plates for each DUT size" (p.5).

Options (sold separately)

Model IM9906 Adapter (3.5 mm/7 mm)..........................................................................(7)

Model IM9905 Calibration Kit (LOAD)............................................................................(8)

Model IM9905 Calibration Kit (OPEN)............................................................................(9)

Model IM9905 Calibration Kit (SHORT) .........................................................................(10)

Magnifying glass (Model IM9200 Test Fixture Stand accessory) ...................................(11)

Model IM9200 Test Fixture Stand

Options (sold separately) can be stored inside (7) to (11) of the carrying case. Please store them after

removing the packed sponge at the time of unpacking.