Insulation Tester IR4053

1

HIOKI Technical Notes Vol. 2 2016 No. 1

measurement. Furthermore, the instrument provides voltage

measurement functionality for measuring voltages of up to

1000 V DC, a capability that is ideal for measuring the no-

load voltage of solar panels.

In addition, the instrument provides ordinary insulation

resistance measurement functionality (with ve ranges)

that complies with Japanese Industrial Standards (JIS)

C1302, allowing measurement of the insulation resistance

of equipment other than solar panels.

The IR4053 is available in two congurations: as the

IR4053-10, which includes standard-type test leads, and as

the IR4053-11, which includes switched test leads, for the

Japanese domestic market.

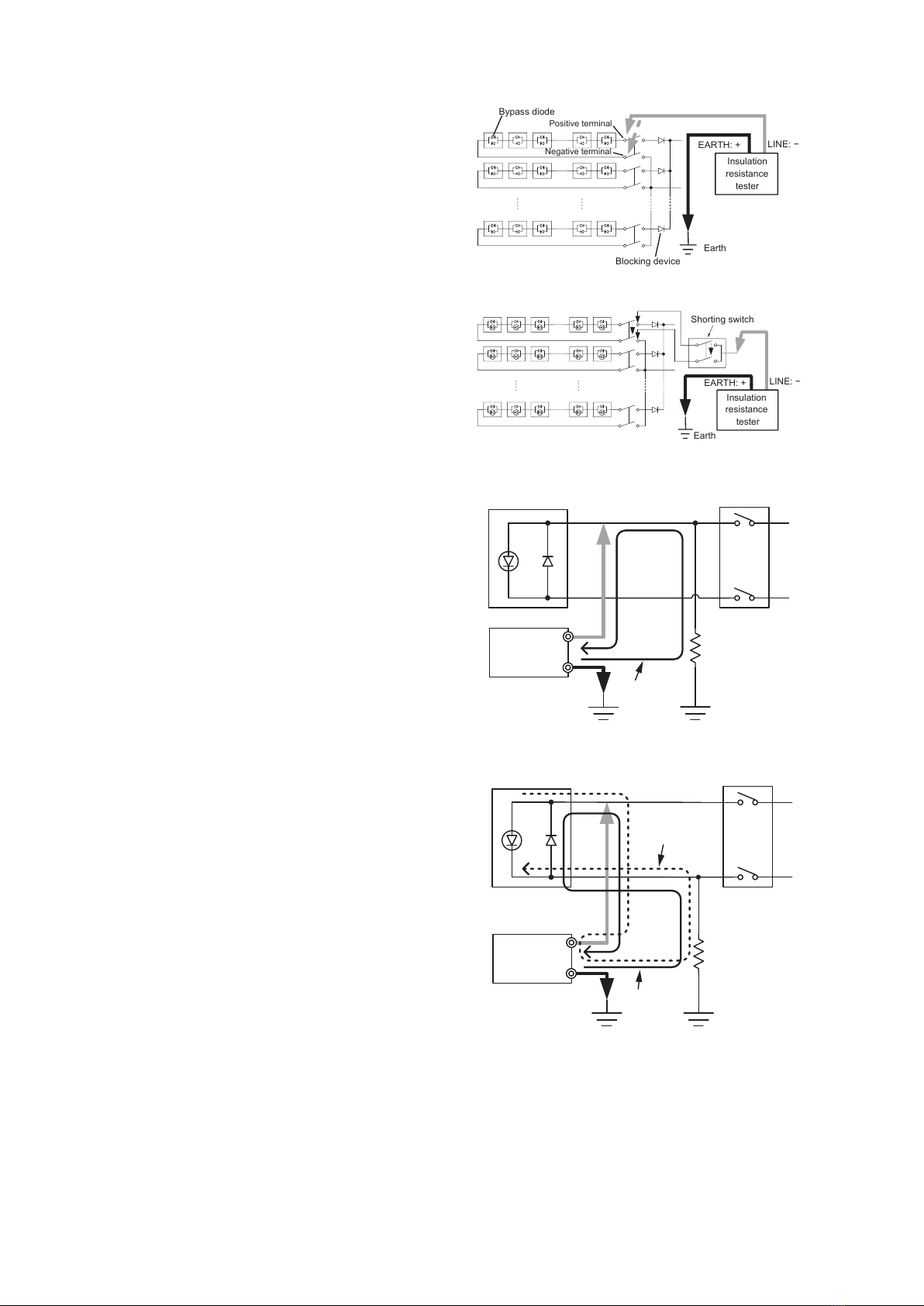

B. Measurement of Solar Panel Insulation Resistance

The technical report JEM-TR228, Maintenance and

inspection guidelines for photovoltaic power generating

systems up to 50 kW for low-voltage network (Japanese),

published by The Japan Electrical Manufactures’

Association, provides important information about the

maintenance and inspection of solar power systems. The

guidelines describe the measurement methods in addition

to the maintenance and inspection items of small-scale solar

power systems, and they recommend that the insulation

resistance of relay terminal boxes (junction boxes and power

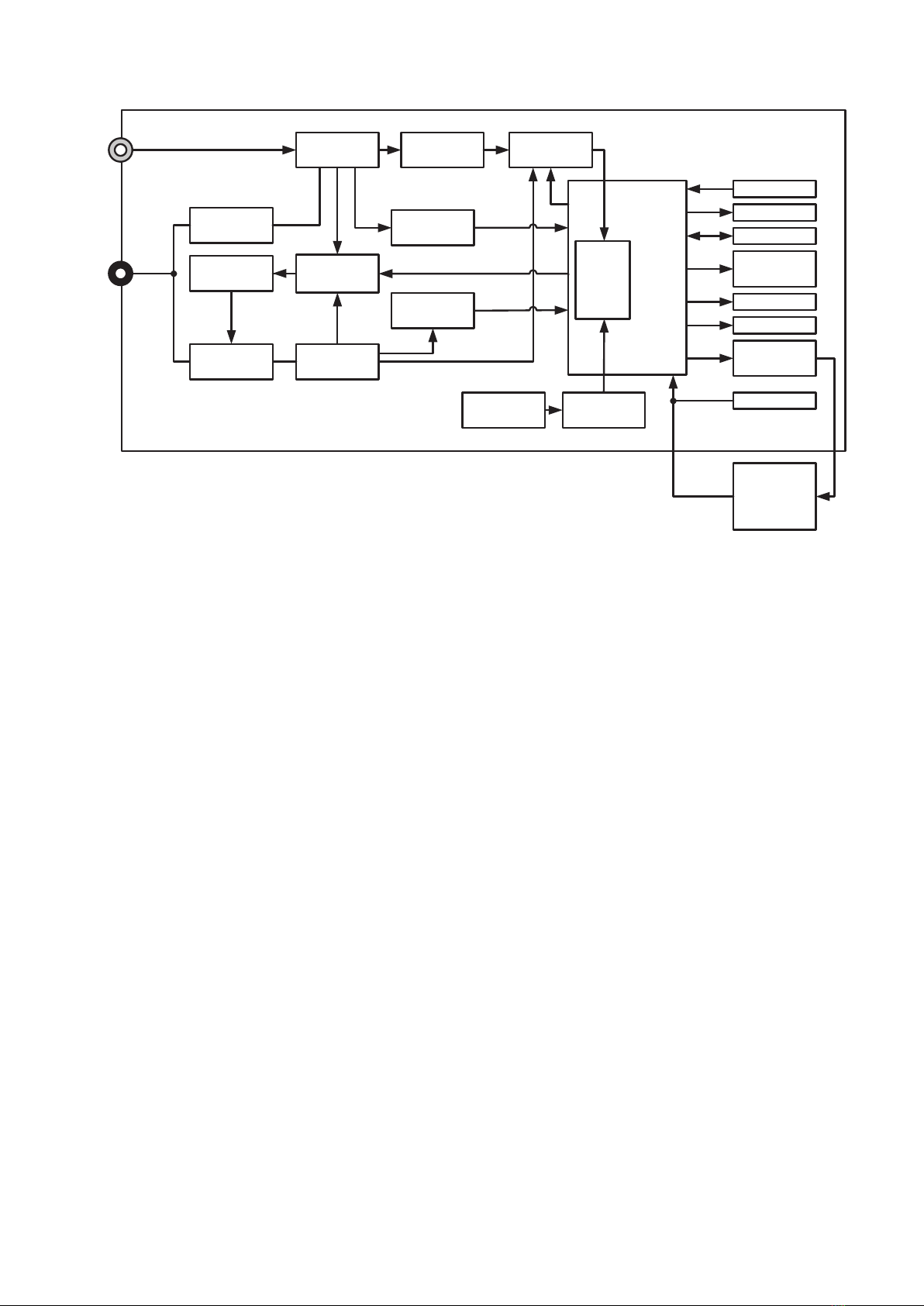

Abstract—The Insulation Tester IR4053 is an insulation

tester designed for use in the maintenance of solar power

system equipment. This paper describes the product’s features,

architecture, and other characteristics.

I. IntroductIon

Due in part to rising awareness of environmental issues,

increasingly serious power shortages, and Japan’s national

initiatives to promote use of solar power in recent years,

there has been rapid growth in use of solar power systems,

from small-scale residential setups to large-scale megasolar

installations. These developments are driving growing

demand for equipment maintenance.

To prevent accidents caused by faulty insulation during

installation and regular inspections of solar power systems,

it is necessary to check the state of insulation by measuring

the insulation resistance at various points in the system.

When using a standard insulation tester to accomplish this

task, the technician must cut off power to the measurement

target before measuring the insulation resistance. In the

case of solar panels, insulation resistance must be measured

while the system is at a dangerous voltage since electricity

is always generated while the system is exposed to sunlight

during the day. Consequently, technicians must exercise a

high level of caution with regard to the hazard of electrical

shock while measuring insulation resistance. In addition,

it is sometimes not possible to obtain accurate resistance

insulation values when a standard insulation tester is used

to test a solar power system because the voltage produced by

the solar panels affects the measurement results.

It was against this backdrop that Hioki developed the

Insulation Tester IR4053 as an instrument that is able to

safely and accurately measure the insulation resistance of

solar panels.

II. overvIew

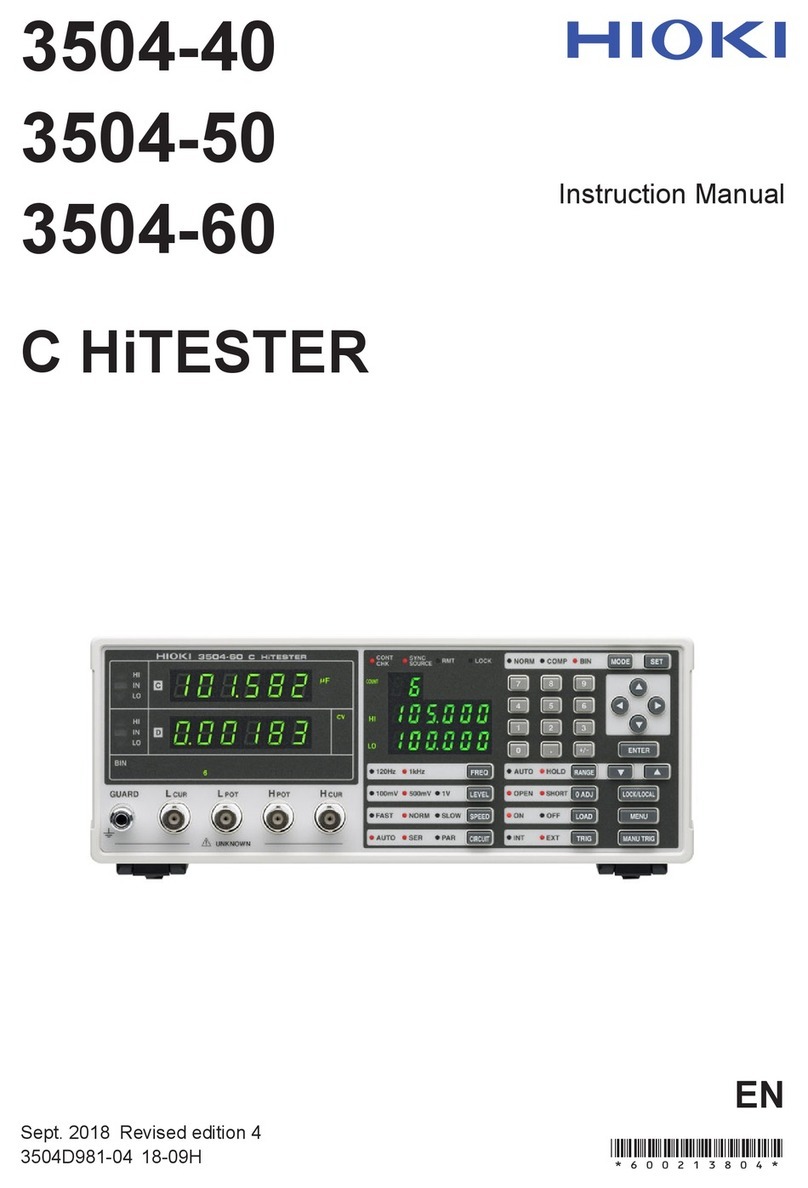

A. Overview of the IR4053

The IR4053 is a portable digital insulation tester.

Developed to be capable of measuring the insulation

resistance of solar panels safely, accurately, and quickly, it is

ideal for maintenance of solar power systems.

The instrument features a new photovoltaic resistance

function designed specically to measure the insulation

resistance of solar panels. This function makes it possible

to accurately measure insulation resistance free from the

effects of the electricity being produced by the panel under

Insulation Tester IR4053

Takeaki Miyazawa

Engineering Division 5, Engineering Department

Appearance of the IR4053.