4

Operating Precautions

Operating Precautions

Observe the following precautionary information to ensure that the device can be used safely and

in a manner that allows it to perform as described in its specications.

Use of the device should conrm not only to its specications, but also to the specications of all

accessories, options and other equipment in use.

Installation Environment

WARNING

Installing the device in inappropriate locations could cause a malfunction of the

device, an accident. Avoid locations that are:

•Exposed to direct sunlight or high temperatures

•Exposed to corrosive or combustible gases

•Exposed to strong electromagnetic elds or electrostatic charges

•Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

•Susceptible to vibration

•Exposed to water, oil, chemicals, or solvents

•Exposed to high humidity or condensation

•Exposed to high concentrations of dust particles

CAUTION

Do not place the device on an unstable or uneven surface. Doing so could cause the

device to fall or turn over, causing bodily injury or damage to the device.

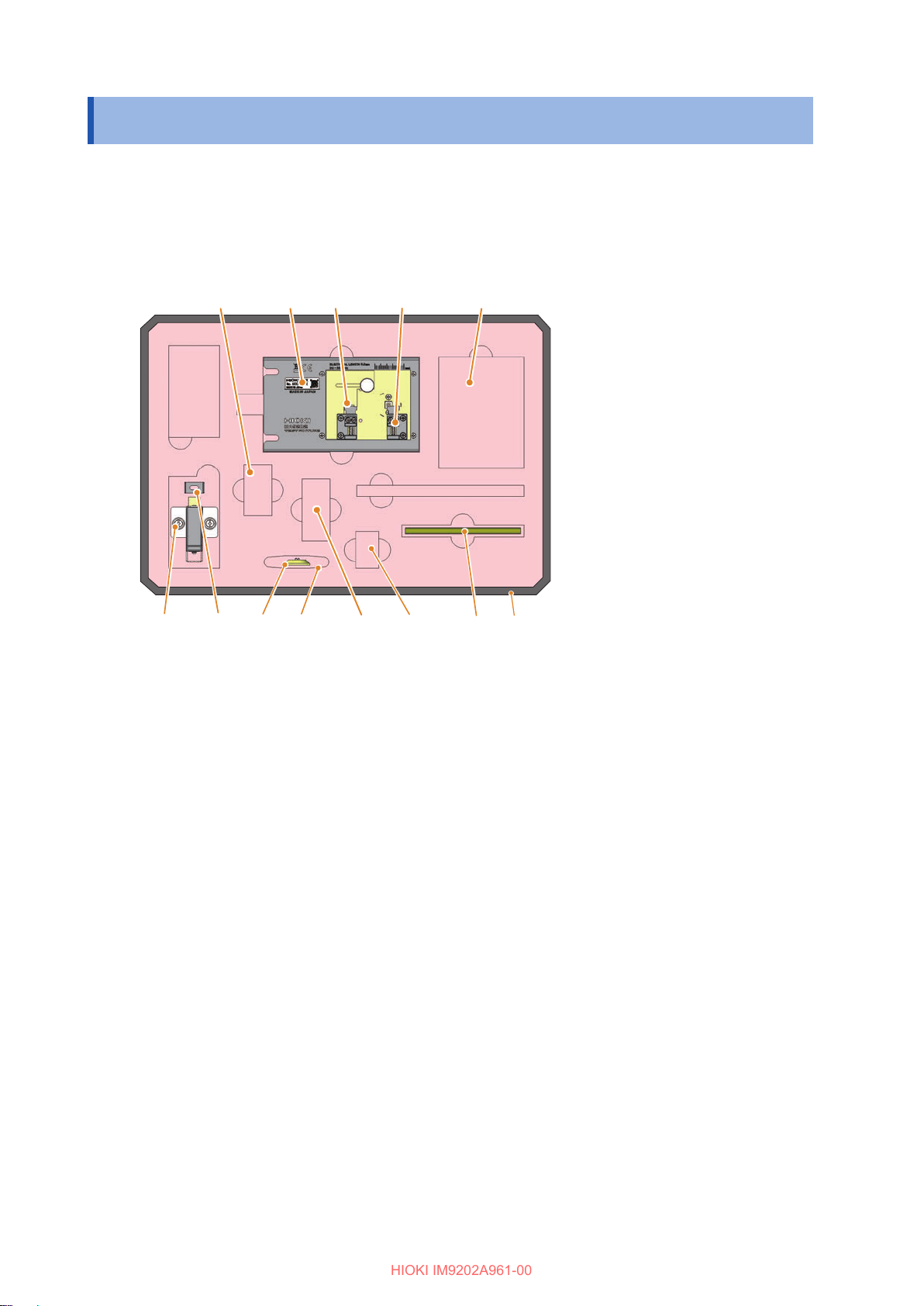

Handling the Device

CAUTION

• The DUT could pop off the device and into the air while being connected. To prevent

injury, use gradual movements when handling clips and electrodes.

• To avoid damage to the device, avoid subjecting it to vibration or mechanical shock

during transportation and handling. Exercise particular care to avoid subjecting the

device to mechanical shock, for example by dropping.

• To prevent device damage or an electric shock, use only the screws that are originally

installed for securing clips or the short plate in place. If you have lost any screws or

nd that any screws are damaged, please contact your authorized Hioki distributor or

reseller.

Measurements

CAUTION

• To avoid bodily injury or damage to the device, do not attempt to measure voltage

exceeding 42V.

• To avoid damage to the device, do not connect the charged capacitor to the device.

• Do not apply a voltage across the device’s measurement terminals while it is

connected to an impedance analyzer.

It may cause damage to the impedance analyzer.

IMPORTANT

The accuracy of measured values obtained using the device is not guaranteed. Measured values

should be treated as reference values.

Shipping Precautions

During shipment of the device, handle it carefully so that it is not damaged due to a vibration or

shock.