iv

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

DANGE

Be sure to ensure the floating state for a battery circuit (measured

object) with voltage exceeding 30 Vrms, 42.4 Vpeak, or 60 VDC.

Connecting the instrument to a circuit exceeding 30 Vrms, 42.4

Vpeak, or 60 VDC may lead to electric shock.

WARNIN

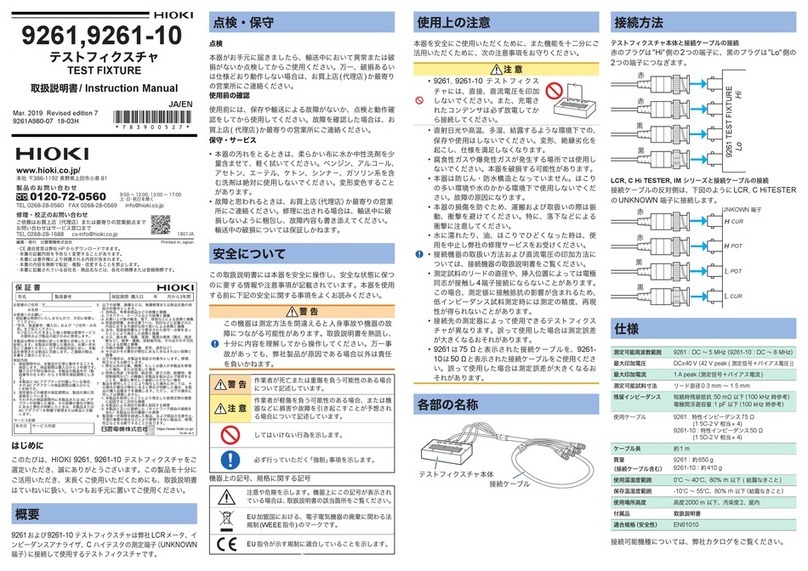

Connect SOURCE and SENSE (banana plug) in the proper manner.

For the correct procedure, refer to Section 3.3 "Connecting the

Measurement Leads ".

To avoid injury or damage to the instrument, do not attempt to

measure AC voltage, or DC voltage exceeding 60 V.

Do not allow the instrument to get wet, and do not take

measurements with wet hands. This may cause an electric shock.

Do not use the instrument where it may be exposed to corrosive or

combustible gases. The instrument may be damaged or cause an

explosion.

To avoid electric shock when measuring live lines, wear appropriate

protective gear, such as insulated rubber gloves, boots and a safety

helmet.

CAUTIO

・Do not store or use the instrument where it could be exposed to direct

sunlight, high temperature or humidity, or condensation. Under such

conditions, the instrument may be damaged and insulation may

deteriorate so that it no longer meets specifications.

・This instrument is designed for use indoors. It can be operated at

temperatures between 0 and 40℃without degrading safety.

・Do not input voltage and current between SOURCE-Hi and SENSE-Hi or

between SOURCE-Lo and SENSE-Lo.

・Various connectors are provided on the outer panel of the instrument.

Make sure the instrument is turned off before connecting cables to these

connectors. To prevent short-circuits, make sure connections are made

correctly.

・The GND terminals on the external control terminal, external output

terminal, RS-232C interface, GP-IB interface, and printer interface are

grounded. This means that the devices connected to the GND terminals

are grounded. Take care in handling them.

otes on Use

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

Preliminary Checks

Before using the instrument the first time, verify that it operates

normally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki

representative.

Before using the instrument, make sure that the insulation on the

measurement leads is undamaged and that no bare conductors are

improperly exposed. Using the instrument in such conditions could

cause an electric shock, so contact your dealer or Hioki representative

for replacements.