Contents

ii

Using Alligator Clips (when using two

or three test leads) .................................................78

Chapter 6 Measurements 79

6.1 Making manual measurements 79

6.2 Making automatic measurements

................................................. 82

6.3 Measurement examples ...........83

Earth leakage current measurement ......... 83

Touch current measurement ..................... 84

Patient leakage current measurement*

(Patient connection - Earth) ..................... 90

Patient leakage current measurement*

(external voltage on a SIP/SOP).............. 93

Patient leakage current measurement*

(external voltage on a specific F-type

applied part) ............................................. 95

Patient leakage current measurement*

(external voltage on metal accessible part

not protectively earthed) .......................... 97

Patient auxiliary current measurement* .... 99

Total patient leakage current measurement*

(Patient connection - Earth)................... 100

Free current measurement

(Enclosure - Enclosure) ......................... 101

6.4 Saving Measurement Data

(As required).......................... 102

Checking Saved Measurement Data ....... 104

Displaying Saved Measurement Data ..... 104

Selecting Saved Measurement Data ...... 105

Deleting Saved Data ............................... 105

6.5 Saving Measurement Conditions

(Panel Save Function)

(as required) ..........................106

6.6 Printing Measurement Data

(as required) ..........................108

Setting up and connecting a printer ......... 108

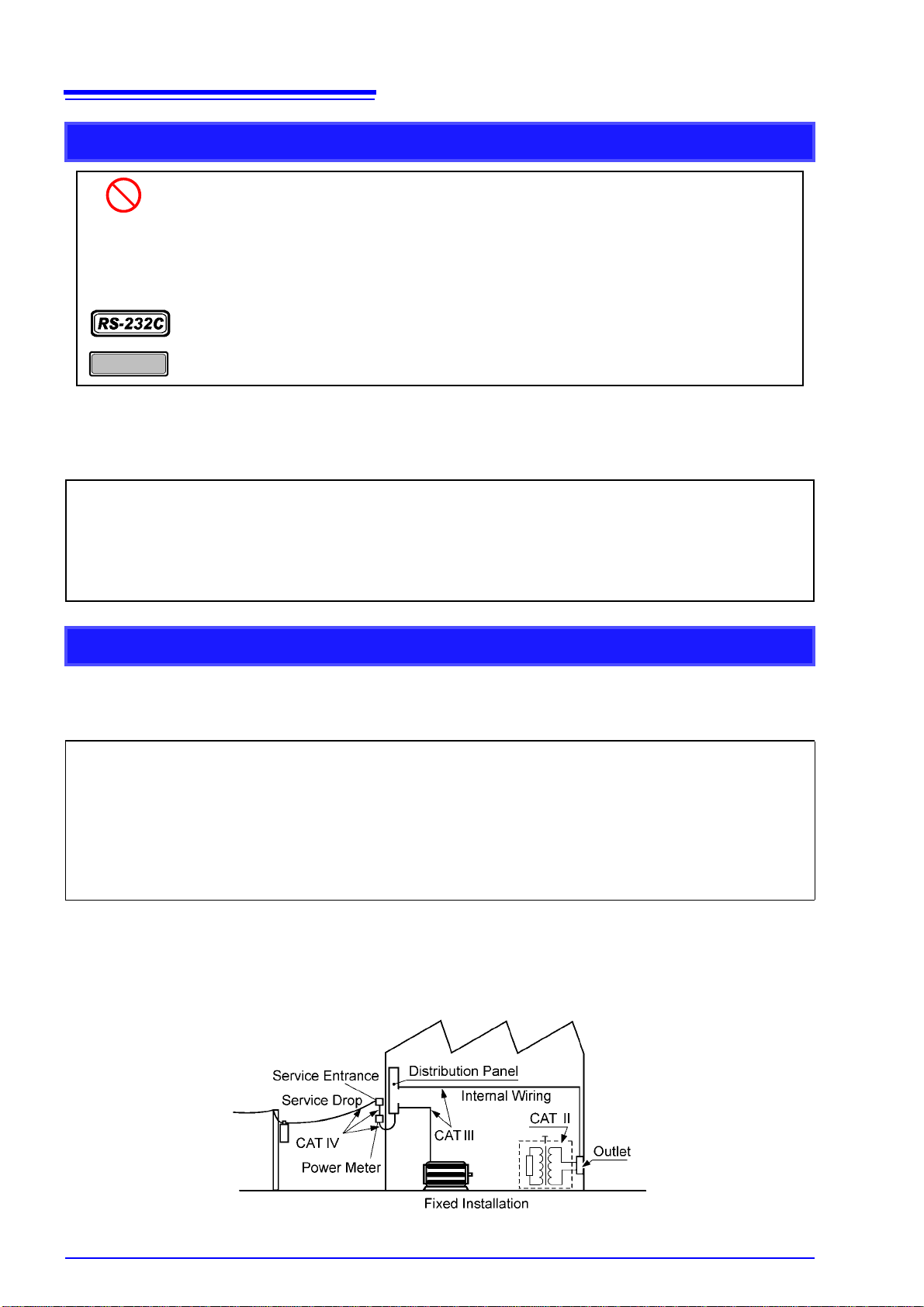

Chapter 7 Instrument System

Settings 115

System Screen Configuration .................. 116

7.1 Setting the Mode (To use the

instrument as a voltmeter) .....117

7.2 Panel Load(Loading Saved

Measurement Conditions)...... 120

7.3 Initializing the Instrument .......121

7.4 Setting the Display Language 123

7.5 Checking Fuses(During Earth

leakage current and protective

conductor current measurements)

................................................123

7.6 Self-Test .................................124

7.7 Power On Polarity Switching

(to keep equipment under test

on during polarity switching) .. 126

Connect the isolation transformer............ 126

Setting Power On Polarity Switching .......127

Relay check 2 .......................................... 128

7.8 Auto Measure Setting

(set instrument status) ........... 129

7.9 Setting Lower Limit Values (factor)

............................................... 130

7.10 Setting Indication Unit ............131

7.11 Setting Date and Time ...........132

7.12 Interface Setting

(For Communication and Printing)

................................................133

7.13 Setting the Beep Sound .........135

7.14 Setting the Backlight.............. 136

Chapter 8 Controlling the

Instrument From a

Computer

(RS-232C,

USB interface) 139

8.1 ST5540/ST5541 Remote Interface

Overview (USB connection) ...140

8.2 Connect and be sure to tighten

the screws on the connector.. 141

Installation and operation procedures .....143

Specifications of RS-232C....................... 144

Specifications of USB .............................. 144