iv

Contents

8 Communications(RS-232Cinterface) 113

8.1 Interface Overview and Features........................................113

8.2 Using the RS-232C Interface...............................................114

■Setting communications conditions..................................................114

■Connecting the RS-232C cable........................................................115

8.3 AutomaticallyExportingMeasuredValuesattheEnds

ofTests(Dataoutputfunction) ...........................................117

8.4 ControllingtheInstrumentandAcquiringDatawith

Commands............................................................................119

■Remote and local states...................................................................119

■Displaying communications commands (Communications monitor

function)............................................................................................120

8.5 DataFormatTable ................................................................125

8.6 Command Reference ...........................................................126

9 Specications 151

■Environment and safety....................................................................151

■Output (output accuracy)..................................................................151

■Resistance measurement ................................................................153

■Input .................................................................................................154

■Guaranteed accuracy.......................................................................154

■Test duration ....................................................................................155

■Response time .................................................................................156

■Functions..........................................................................................156

■External interface .............................................................................159

■Other specications..........................................................................162

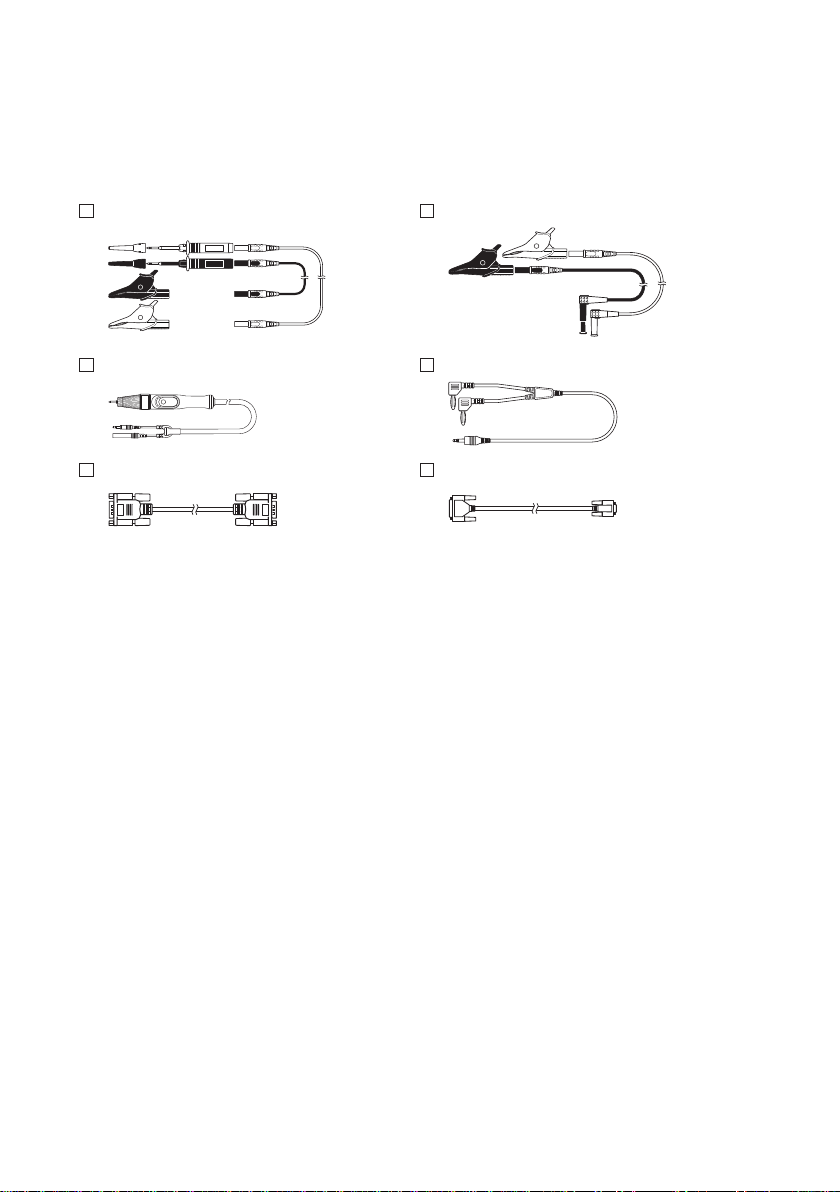

■Accessories......................................................................................164

■Options.............................................................................................164

10 Maintenance and Service 165

10.1 Maintenance .........................................................................165

10.2 Troubleshooting ...................................................................167