HARDWIRE ZONE CONNECTION

AC POWER CONNECTIONAC POWER CONNECTION

GND Z5Z4GNDZ3Z2GNDZ1+OUTINAUXAC

YELLOW

GREEN

GRAY

BROWN

AC BELL GND GNDRINGTIPRING

INCOMING

HANDSET

TIPZ8GND Z6 Z7

1237811 12 17 20 21 22 23 24 25

18 19

16

15

14

13

10

9

6

45

Z1

EARTH

GROUND

AFTER ALL WIRING CONNECTIONS ARE COMPLETE, PLUG

TRANSFORMER INTO A 110VAC UNSWITCHED OUTLET (24HR)

CONNECT ONLY AFTER AC POWER HAS BEEN APPLIED.

USE 1361X10 TRANSFORMER INTERFACE WHEN POWER

LINE CARRIER DEVICES ARE BEING USED.

BLACK

RED

2-WIRE SMOKE

DETECTORS

(16 MAX) OR

STANDARD

2K EOLR

PREMISES

PHONES

INCOMING

TELCO

RING (GRAY)

TIP (BROWN)

RING (RED)

TIP GREEN)

RJ31X

12 3

4

5

67

8

ZONE

PAIRS

2 / 10

3 / 11

4 / 12

5 / 13

6 / 14

7 / 15

8 / 16

1312 14

10 11

6.2k

ZONE 10

3k

ZONE 2

2k

2k

2k

ZONE 3

2k

2k

2k

ZONE 4

TAMPER

CONTACTS

TAMPER

CONTACTS

1321

(1321CN IN CANADA)

16.5VAC, 40VAC, CLASS 2

PLUG-IN TRANSFORMER

BATTERY

(12V, 4AH)

TRANSFORMER WIRE RUNS

"AC LOSS" DISPLAYED IF VOLTAGE FALLS BELOW 16.5VAC.

CONNECT THE TRANSFORMER TO TERMINALS 1 AND 2.

SEE WIRE RUN CHART.

Distance from control Wire Size

# 18

# 16

# 20

50 - 100 feet

100 - 200 feet

Up to 50 feet

HARDWIRE ZONES

ECP DEVICES

PLACE THE 12-VOLT BACKUP BATTERY IN THE CABINET.

AFTER ALL CONNECTIONS TO THE CONTROL ARE MADE AND

AC POWER HAS BEEN APPLIED, CONNECT THE RED AND

BLACK FLYING LEADS TO THE BATTERY.

IMPORTANT: THE PANEL WILL NOT POWER UP INITIALLY ON

BATTERY POWER ONLY.YOU MUST PLUG THE TRANSFORMER

IN FIRST, AND THEN CONNECT THE BATTERY.

ZONE DOUBLING

DOUBLE-BALANCED ZONE

UL NOTE:

SET RECEIVER DEVICE ADDRESS TO "00" (SET SWITCHES TO

THE RIGHT, "OFF" POSITION).

MOUNT THE RECEIVER INSIDE THE CABINET OR REMOTELY

WITHIN A NOMINAL RANGE OF 200 FEET FROM TRANSMITTERS,

IN HIGH, CENTRALLY LOCATED AREA.

CONNECT THE RECEIVER'S WIRE HARNESS TO THE CONTROL'S

ECP TERMINALS. SEE RECEIVER'S INSTRUCTIONS FOR

ANTENNA MOUNTING, ETC.

INSTALL TRANSMITTERS ACCORDING TO THEIR INSTRUCTIONS.

VISTA-15P:

TRANSMITTER ZONES 9-34

BUTTON ZONES 49-56

VISTA-20P:

TRANSMITTER ZONES 9-48

BUTTON ZONES 49-64

WIRELESS ZONE NUMBERS

1.

2.

DO NOT USE DOUBLE-BALANCED ZONES

OR ZONE DOUBLING FOR FIRE ZONES.

OPEN CIRCUIT DEVICES CONNECT IN PARALLEL ACROSS

THE LOOP; FOR EOLR ZONES, CONNECT THE EOLR

ACROSS THE LOOP WIRES AT THE LAST DEVICE.

CLOSED CIRCUIT DEVICES CONNECT IN SERIES IN THE

HIGH (+) SIDE OF THE LOOP; FOR EOLR ZONES, CONNECT

THE EOLR IN SERIES FOLLOWING THE LAST DEVICE.

1.

2.

FOR UL COMMERCIAL BURGLARY ALARM INSTALLATIONS,

USE EOLR ZONES.

EOLR NOTE:

IF THE EOLR IS NOT AT THE END OF THE LOOP, THE

ZONE IS NOT PROPERLY SUPERVISED AND THE SYSTEM

MAY NOT RESPOND TO AN "OPEN" ON THE ZONE.

USE CAUTION WHEN WIRING

THE TRANSFORMER TO THE

CONTROL TO GUARD AGAINST

BLOWING THE TRANSFORMER

FUSE (THE FUSE IS

NON-REPLACEABLE).

SOUNDER CONNECTION

RF RECEIVERS & TRANSMITTERS

AC POWER AND BATTERY CONNECTION

1.

2.

PHONE CONNECTION

CONNECT PHONE LINE DIRECT

CONNECT CABLE WIRES TO

TERMINALS 21-24 AS SHOWN.

WIRE COLORS REPRESENT THE

COLORS OF THE CABLE TO THE

RJ31X JACK.

CONNECT INCOMING PHONE

LINE AND HANDSET WIRING TO

THE MAIN TERMINAL BLOCK

(VIA AN RJ31X JACK; CA38A IN

CANADA) AS SHOWN.

1.

2.

EARTH GROUND CONNECTION

KEYSWITCH WIRING CONNECTIONS

METAL COLD WATER PIPE: USE A NON-CORROSIVE METAL STRAP

(COPPER IS RECOMMENDED) FIRMLY SECURED TO THE PIPE TO WHICH

THE GROUND LEAD IS ELECTRICALLY CONNECTED AND SECURED.

AC POWER OUTLET GROUND: AVAILABLE FROM 3-PRONG, 120VAC

POWER OUTLETS ONLY. TO TEST THE INTEGRITY OF THE GROUND

TERMINAL, USE A 3-WIRE CIRCUIT TESTER WITH NEON LAMP

INDICATORS, SUCH AS THE UL LISTED IDEAL MODEL 61-035, OR

EQUIVALENT, AVAILABLE AT MOST ELECTRICAL SUPPLY STORES.

THIS CONTROL DOES NOT NORMALLY NEED AN EARTH GROUND. IF

DESIRED FOR ADDITIONAL PROTECTION, CONNECT TERMINAL 25 TO A

GOOD EARTH GROUND. EXAMPLES OF GOOD EARTH GROUNDS:

DEVICE ADDRESS DEVICE ADDRESS

KEYPADS 16 - 23 5800TM 28 (PART. 1 ONLY)

4219, 4229 07 - 11 COMM DEVICE 03

4204 12 - 15 4286 04

RF RECIEVER 00 TOUCH SCREENS 01, 02, 05, 06

CONNECT KEYPADS AND OTHER ADDRESSABLE DEVICES TO ECP TERMINALS 4-7.

(SEE "SETTING KEYPAD ADDRESS BOX TO SET KEYPAD ADDRESSES.)

KEYPADS AND ADDRESSABLE DEVICE CONNECTION

V15P_V20P_quick-guide

TRIGGER CONNECTOR

USED FOR 1361X10

TRANSFORMER

CONNECTIONS AND FOR

ON-BOARD TRIGGERS.

(USE SA4120XM-1 CABLE)

78

RED JUMPER

CUT FOR BELL SUPERVISION. ALSO,

CONNECT 2000 OHM RESISTOR DIRECTLY

ACROSS SOUNDER AND ENABLE FIELD 91.

GND

+12 AUX

1234 5 6

OUTPUT 18

(TRIG. 2)

OUTPUT 17

(TRIG. 1)

BATTERY FUSE

FOR

REPLACEMENT,

USE SAME VALUE

(e.g. ADEMCO No. 90-12)

3A

ZONE 1

HI

HI

LO

HI

LO

LO

2000

OHMS

EOLR

2000

OHMS

EOLR

ZONE 2

2000

OHMS

EOLR

ZONE 3

HI

HI

LO

LO

2000

OHMS

EOLR

ZONE 6

HI

HI

LO

LO

2000

OHMS

EOLR

2000

OHMS

EOLR

2000

OHMS

EOLR

ZONE 4

ZONE 8

2000

OHMS

EOLR

ZONE 7

ZONE 5

YELLOW

GREEN

RED

BLACK

YELLOW

GREEN

RED

BLACK

1.

2.

FOR SOUNDER SUPERVISION

BATTERY

TRANSFORMER

1.

2.

3.

4.

IF BELL SUPERVISION IS

ENABLED (RED JUMPER ON

CONTROL BOARD IS CUT

AND 91 ENABLED)

CONNECT A 2000 OHM

RESISTOR ACROSS THE

EXTERNAL SOUNDER AS

SHOWN BY THE DOTTED LINE.

CONNECT SOUNDER TO BELL TERMINALS 3 (+) AND 4 (-).

SOUNDER ACTIVATES UPON ALARM EVENT.

10.5–13.8VDC, 2A MAX. (600mA MAX. FOR UL USAGE,

INCLUDING AUX POWER) STEADY FOR BURGLARY/PANIC,

TEMPORAL PULSE SOUNDING FOR FIRE.

CAN USE ADEMCO No. 702 SIREN, OR 12V BELL.

A BATTERY MUST BE INSTALLED BECAUSE THE BATTERY

SUPPLIES THE CURRENT.

EXTERNAL ALARM SOUNDER

2000 OHM

EOL

RESISTOR

OBSERVE

POLARITY

TERM 5

TERM 4

DO NOT CONNECT THE RESISTOR ATTHE ALARM OUTPUT TERMINALS THEMSELVES!

10.5-13.8VDC 600mA MAX.

(500mA MAX. FOR UL INSTALLATIONS)

OPTIONAL

1361X10

TO

TERMINALS

1 & 2 BLACK (SYNC)

BLUE (DATA)

PURPLE (COM)

78

1234 5 6

ECP AUX POWER OUTPUT

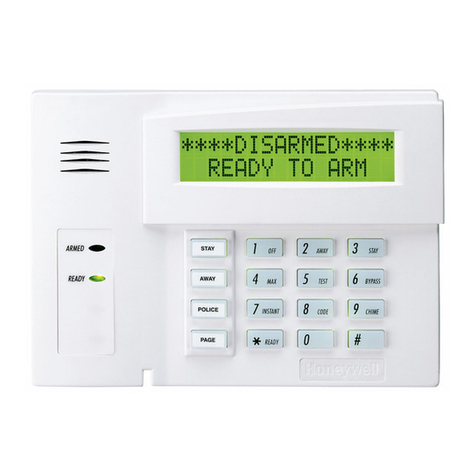

SETTING KEYPAD ADDRESS

POWER UP THE KEYPAD.WITHIN 60 SECONDS OF

POWER-UP, PRESS AND HOLD DOWN THE [1] & [3] KEYS

AT THE SAME TIME FOR 3 SECONDS.

1.

2.

3.

ENTER THE PROPER "TENS" DIGIT OF THE KEYPAD'S

ADDRESS, THEN ENTER THE PROPER "ONES" DIGIT

OF THE KEYPAD'S ADDRESS.

PRESS [ ] TO SAVE THE DISPLAYED ADDRESS AND

EXIT ADDRESS MODE.

4

MAX

7

INSTANT

READY

2

AWAY

5

TEST

8

CODE

0

6

BYPASS

9

CHIME

#

ARMED

READY

1

OFF

3

STAY

HOLD

DOWN

THREE

SECONDS

4146 KEYSWITCH

(READY)

GREEN

LOCK

SWITCH (N. O.)

TAMPER

SWITCH (N. C.)

(ARMED)

RED

YELLOW

WHITE

2K OHM EOLR

11

10

TYPICAL ZONE

ON CONTROL

BOARD

BROWN

BLUE

BROWN

BLUE

820

ohms

820

ohms

STANDARD

KEYPAD

CABLE

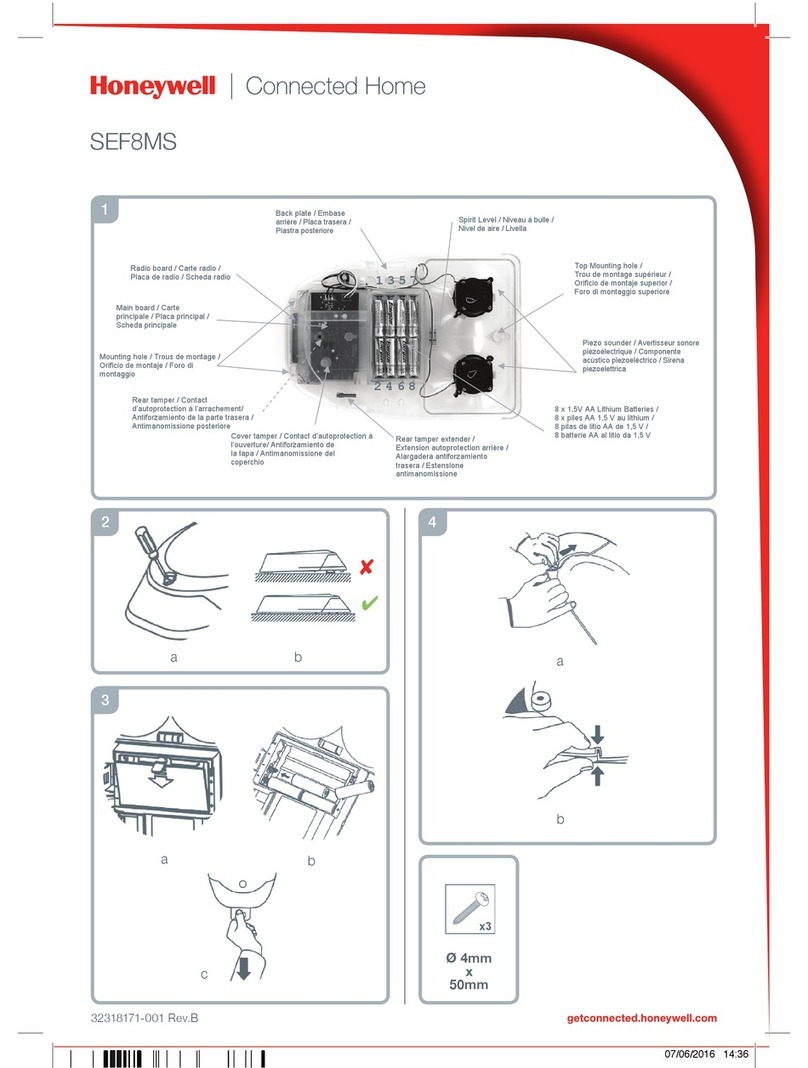

+12 AUX. (RED)

OUTPUT 17 (YEL)

OUTPUT 18 (GRN)

RED

BLACK

SENSORS

(USE 1K EOLR)

4219/4229

EXPANDER

MODULE

RF

RECEIVER

COMMUNICATION

DEVICE

4204

RELAY

MODULE

TOUCH

SCREEN

KEYPAD

KEYPAD

CONTROLLED

DEVICES

ARMED

READY

MESSAGE

TRIGGER CONNECTOR

NOTE: FIRST KEYPAD IS ADDRESS 16

DIRECT CONNECT CORD (620)

4-WIRE SMOKE DETECTOR CONNECTIONS

(+)

+

2000

OHMS

EOLR

HEAT

DETECTOR

RED

EOL

POWER

SUPERVISION

RELAY MODULE

A77-716B.

USE N.O.

CONTACT,

WHICH CLOSES

WHEN POWER

IS APPLIED.

VIOLET

AUX PWR

OUTPUT

TERMINALS

5

4

_

_

+

BLK

_

( )

TO ZONE 2 8 TERM.

RELAY

CONTACT OPENS MOMENTARILY

UPON FIRE ALARM RESET

PROGRAM RELAY

AS ZONE TYPE 54

(FIRE ZONE RESET)

_

+

4-WIRE SMOKE

OR COMBUSTION

DETECTOR

N.C. N.O.

TO OUTPUT 17

PROGRAM OUTPUT 17 FOR

"OUT NORM LOW" = YES IN

79 MENU MODE AND AS ZONE

TYPE 54 IN 80 MENU MODE

MAX. CURRENT = 100 mA

(UP TO 16 DETECTORS

PLUS EOL MODULE)

OR

SET EACH MODULE'S ADDRESS ACCORDINGLY:

TOUCH SCREEN KEYPADS MAY REQUIRE EXTERNAL

POWER SUPPLY DUE TO AUX POWER LIMITATIONS.

ARMED

READY

1

OFF

4

MAX

7

INSTANT

READY

2

AWAY

5

TEST

8

CODE

0

3

STAY

6

BYPASS

9

CHIME

#