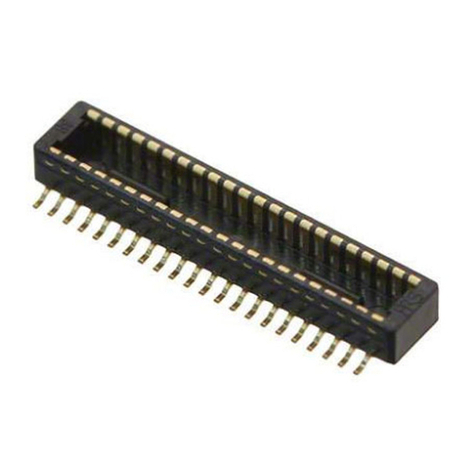

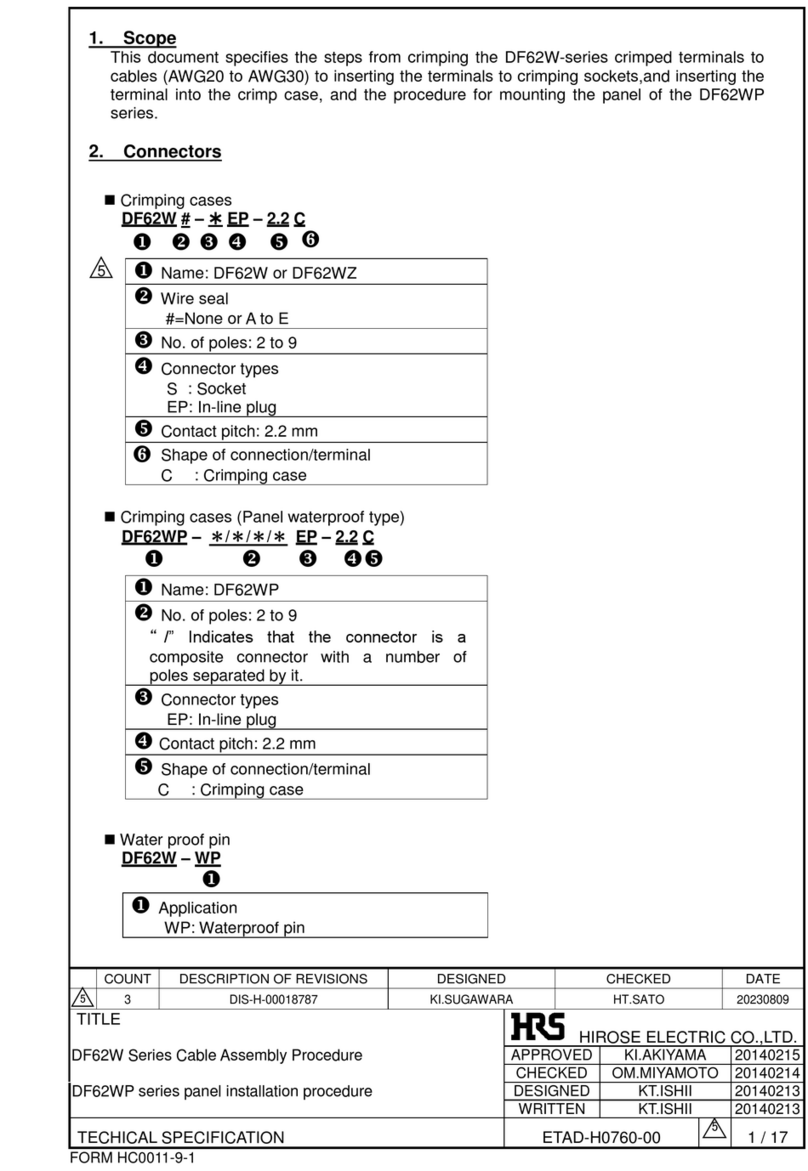

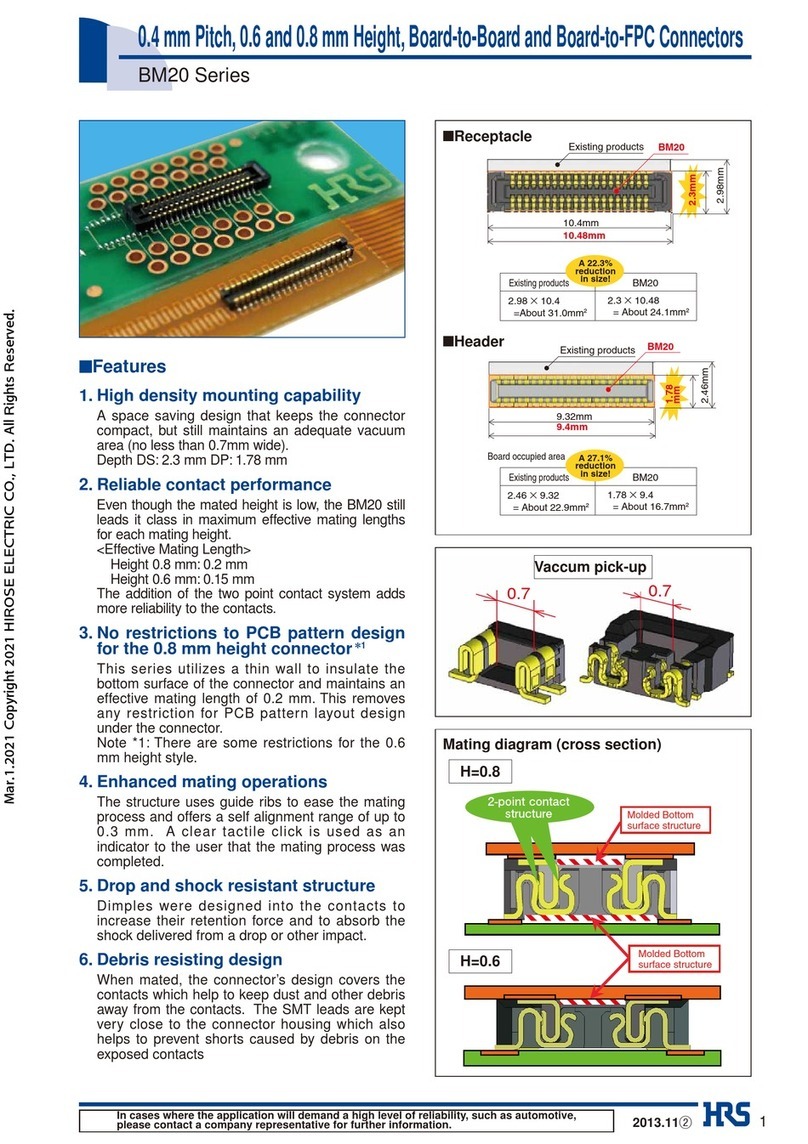

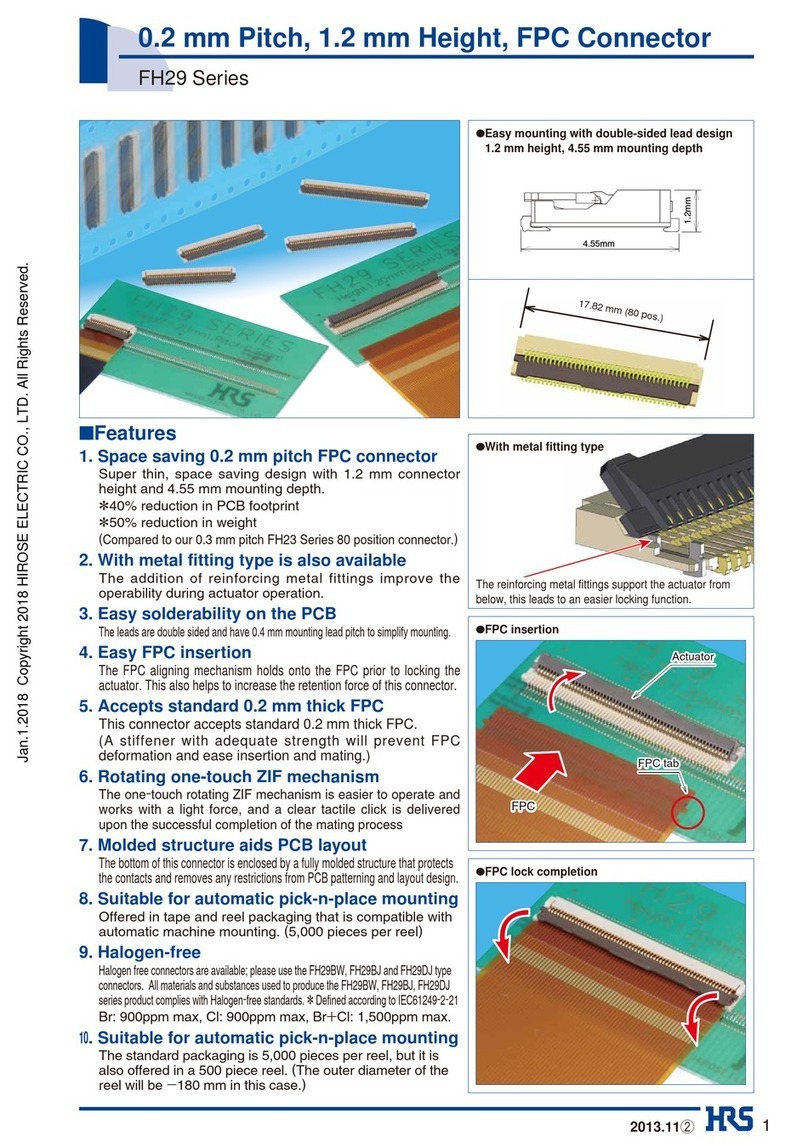

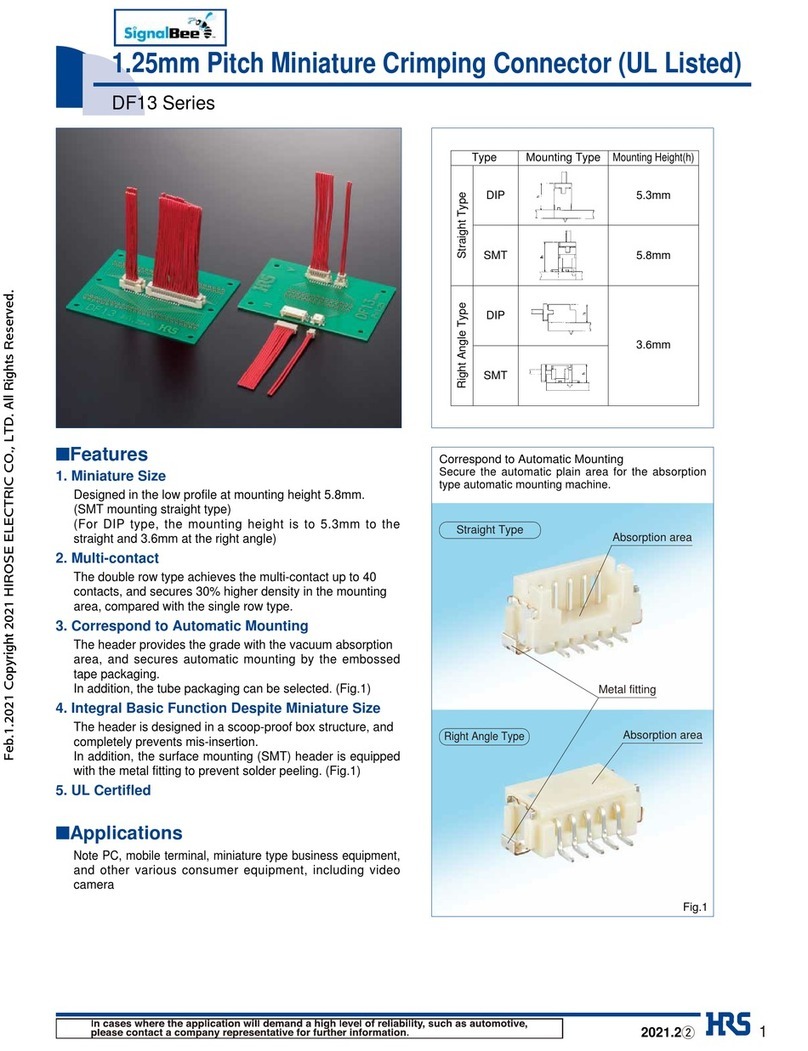

BATTERY BOARD TO FPC CONNECTOR,

Pitch: 0.4mm, Width: 2.6mm,

Stacking height: 0.7mm, Power: 10A

Page Number

1.Notice for Device Designing............................................................................................................................3

1-1 Notice for mechanical designing..........................................................................................................3

1-1.a Disengaging prevention...............................................................................................................3

1-1.b FPC FIXING.................................................................................................................................4

1-1.c Location of other components around connector........................................................................4

1-1.d Marking for mating position .........................................................................................................4

1-2 Notice for PWB designing...................................................................................................................5

1-2.a Recommended PWB pattern.......................................................................................................6

1-2.b PWB pad layout and connector location .....................................................................................6

1-2.c PWB designing ............................................................................................................................7

1-2.d FPC designing.............................................................................................................................8

2. Notice for Mounting....................................................................................................................................10

2-1 Metal mask design ............................................................................................................................10

2-2 Reflow profile.....................................................................................................................................11

2-3 Notice for...........................................................................................................................................12

2-3.a Repairing condition .....................................................................................................................12

2-3.b Solder swelling............................................................................................................................12

3 Notice for Connector Handling

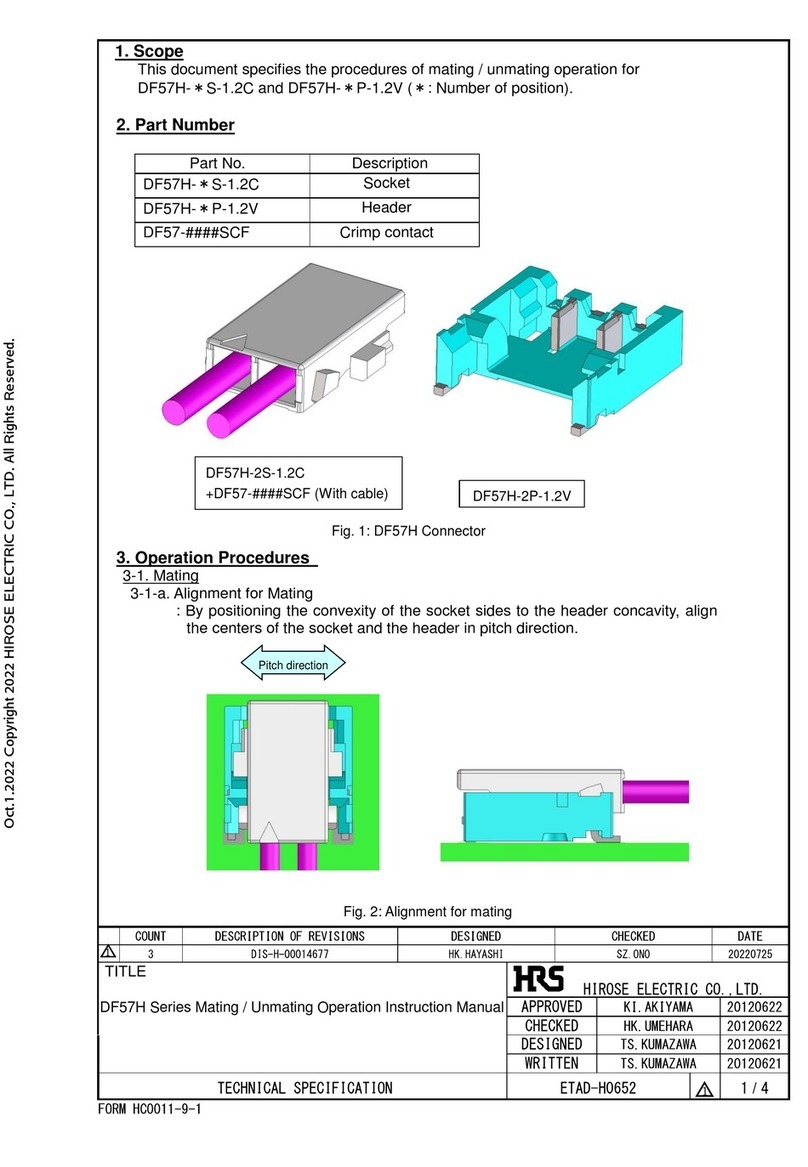

3-1 Connector insertion operation.............................................................................................................13

3-2 Connector withdrawal operation..........................................................................................................14

4 PWB for Evaluation test .................................................................................................................................15

4-1 Contact Resistance Measurement.....................................................................................................15

4-2 Temperature Rise Test.......................................................................................................................16

5 Electrical inspection jig..................................................................................................................................17

5-1 Product name ....................................................................................................................................17

5-2 Electric inspection jig summary ..........................................................................................................17

5-3 Arrangement of the electric inspection jig ...........................................................................................18

5-4 Contact information of YOKOWO CO., LTD. ....................................................................................19

Nov.1.2021Copyright2021HIROSEELECTRICCO.,LTD.AllRightsReserved.