2

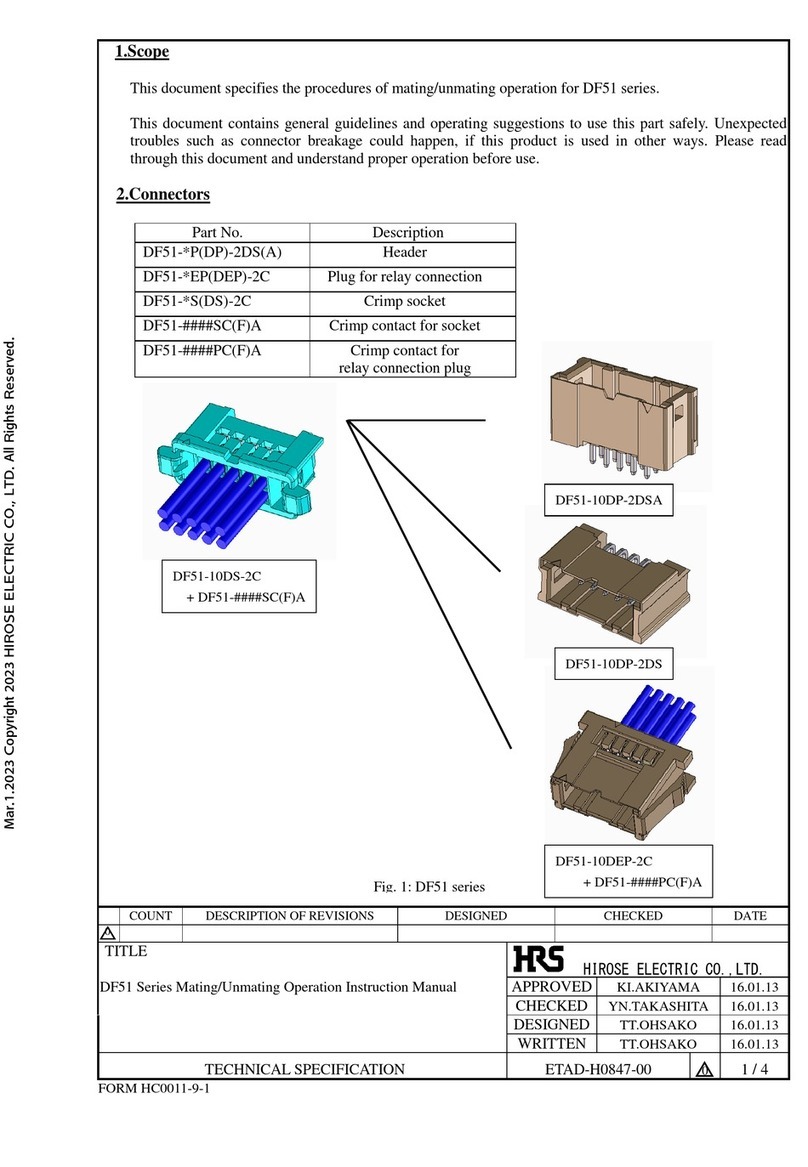

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

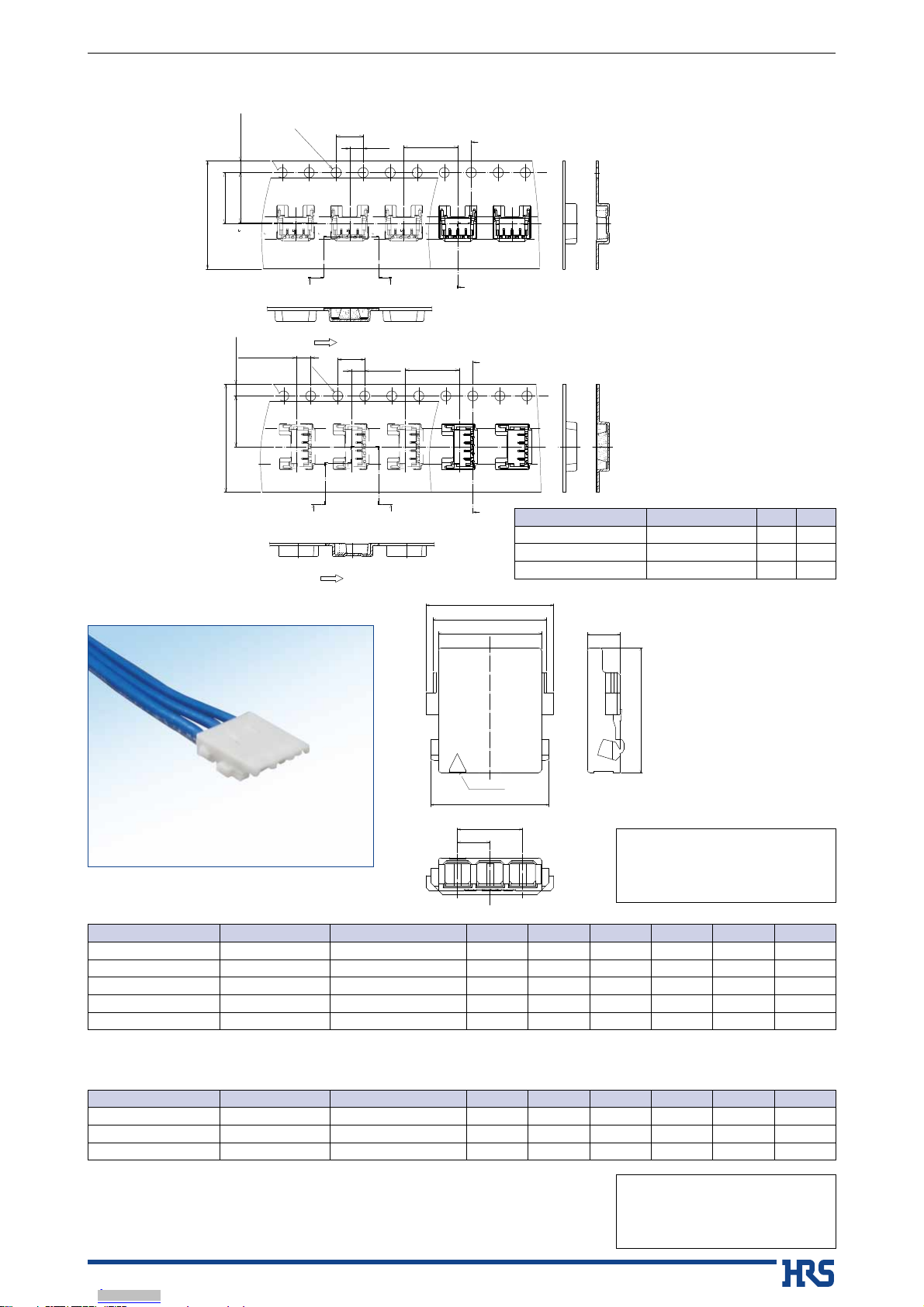

■Specifications

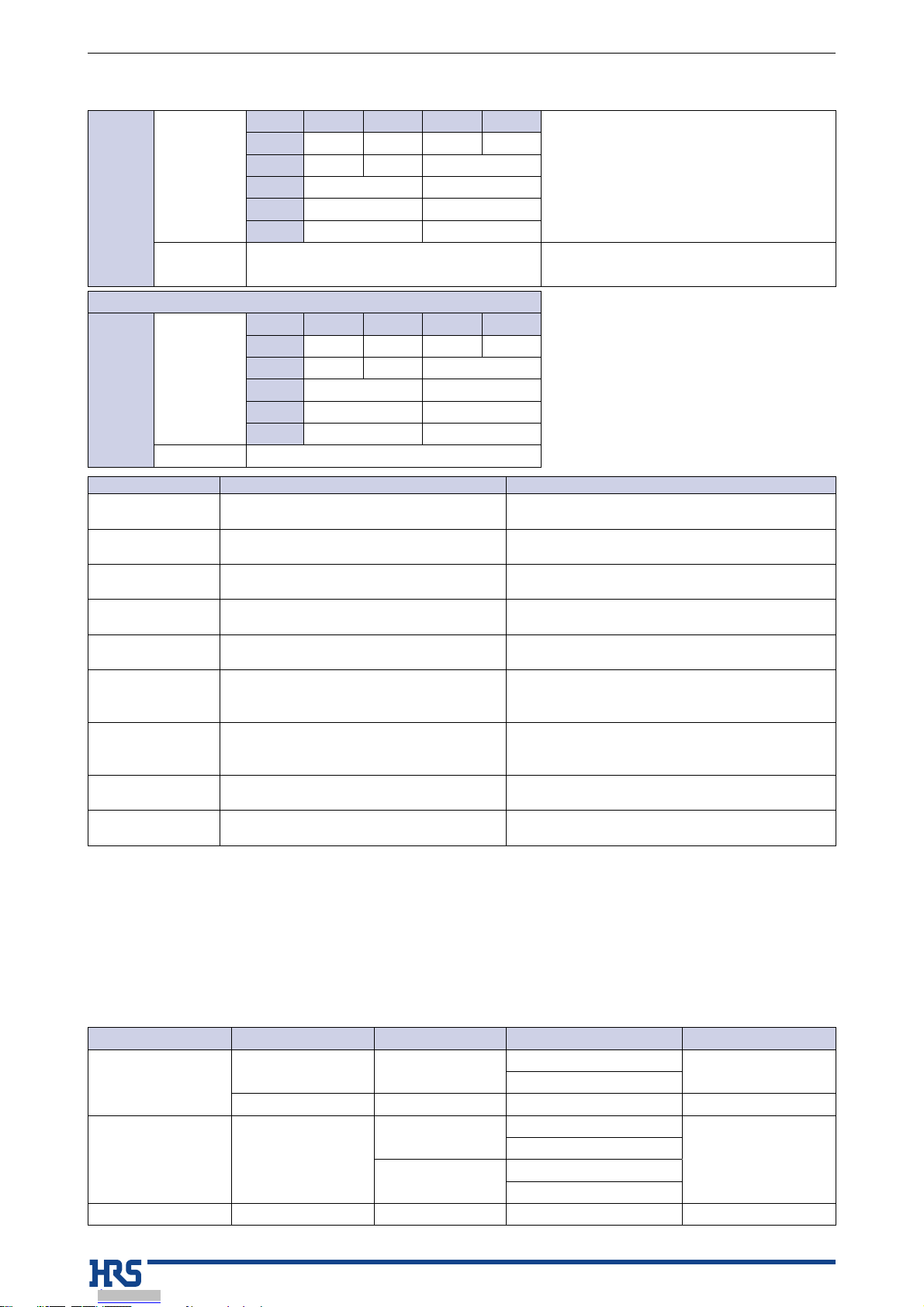

Rating

Current rating

(Note 1)

2pos. 3pos. 4pos. 5,6pos.

Operating temperature range -35ç to 85ç (Note 2)

Operating humidity range 20% to 80% (Note 3)

AWG#26

3.0A _ _ 1.5A

AWG#28

2.5A 2.0A 1.5A

AWG#30

1.5A 1.0A

AWG#32

1.0A 0.8A

AWG#34

0.8A 0.5A

Voltage rating

2 to 6 pos. : 50V AC/DC

2 pos. (Middle pin of 3 pos. is removed) : 100V AC/DC

Storage temperature range -10ç to 60ç (Note 4)

Storage humidity range 40% to 70% (Note 4)

UL, C-UL certified specifications

Rating

Current rating

(Note 1)

2pos. 3pos. 4pos. 5,6pos.

AWG#26

3.0A _ _ 1.5A

AWG#28

2.5A 2.0A 1.5A

AWG#30

1.5A 1.0A

AWG#32

1.0A 0.8A

AWG#34

0.8A 0.5A

Voltage rating 2 - 6 pos. : 29V AC/DC

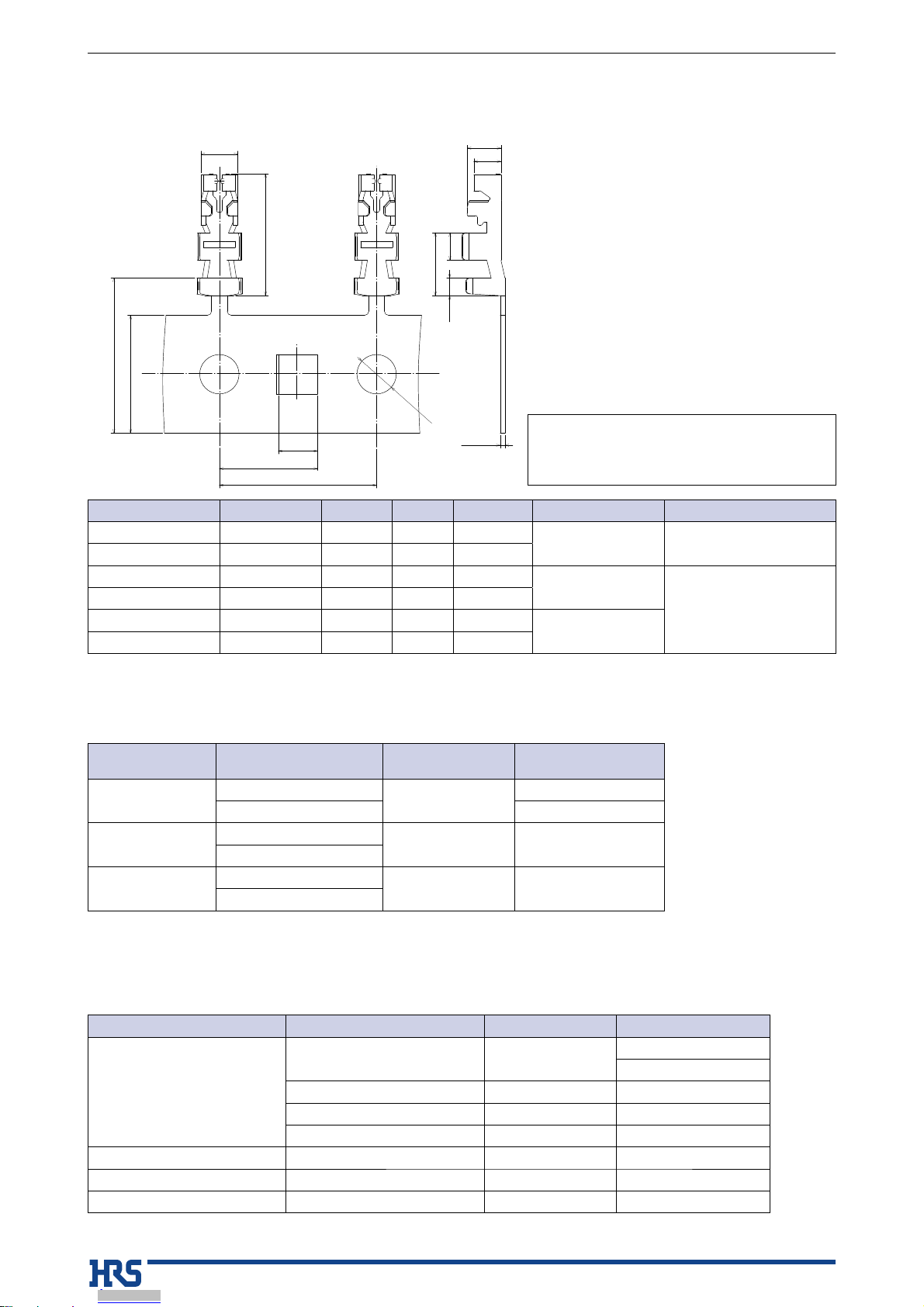

Item Specification Conditions

1.Insulation

resistance 100Mø min. 100V DC

2.Withstanding

voltage

No flashover or insulation breakdown 500V AC / 1 minute

3.Contact

resistance 10mø max. 20mV max., at 1mA.

4.Vibration No electrical discontinuity of 1µs or longer

No damage, cracks or parts dislocation.

Frequency : 10 to 55Hz, single amplitude of 0.75mm,

10 cycles, 3 direction

5.Shock No electrical discontinuity of 1µs or longer

No damage, cracks or parts dislocation.

Acceleration of 490m/s2, 11ms duration, sine half-

wave, 3 cycles in each of the 3 axis

6.Humidity

Contact resistance : 20mø max.,

Insulation resistance : 500Mø min.

No damage, cracks or parts dislocation.

96 hours at 40 ±2ç, and humidity of 90 to 95%

7.Temperature

cycle

Contact resistance : 20mø max.,

Insulation resistance : 500Mø min.

No damage, cracks or parts dislocation.

-55°C →5 to 35°C →85°C →5 to 35°C

Times : 30 min. →2 min. to 3 min. →30 min. →2 min.

to 3 min. 5 cycles

8.Durability Contact resistance : 20mø max.,

No damage, cracks or parts dislocation. 30 cycles

9.Resistance to

soldering heat

No deformation of components affecting

performance

Reflow : At the recommended temperature profile

Manual soldering : 350°C for 3 seconds

Note 1 : This is the maximum current rating while all pins are powered or used as all power lines. When isolating power lines

into multiple circuits, current ratings may go above the stated current ratings. Please consult Hirose for specific details

before doing this.

Note 2 : Includes the temperature rise of power lines.

Note 3 : The connector should be completely dry. (no condensation present)

Note 4 : The term “storage” refers to the long-term storage condition of unused products before PCB mounting. The operating

temperature and humidity ranges are applied while in a non-energized state, while in transport or after PCB mounting.

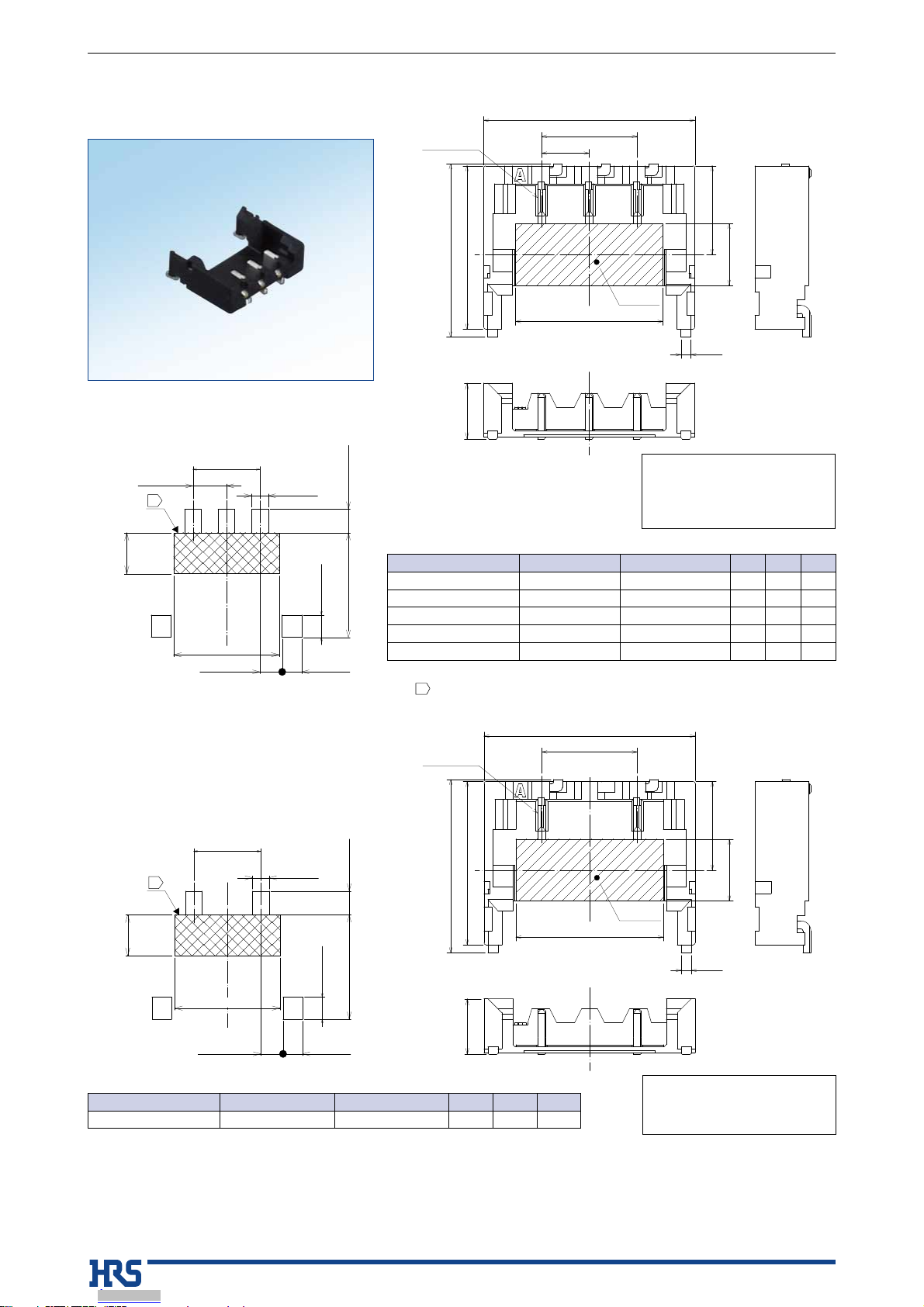

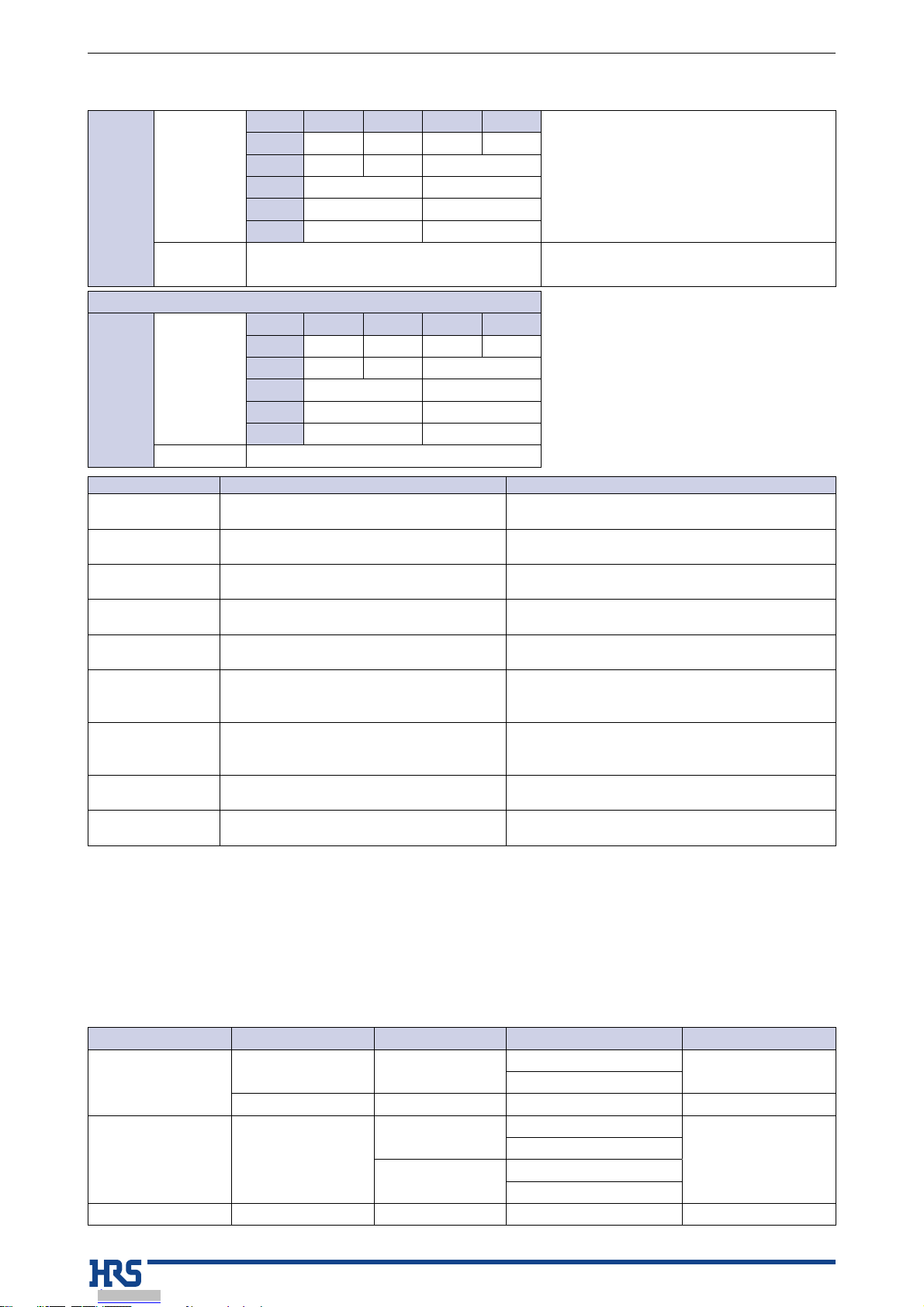

■Material / Finish

Item Component Material Finish UL Flammability rating

Header Insulator LCP Black UL94V-0

Beige

Contact Brass Tin plating or gold plating ---------

Crimp socket Insulator

PBT White

UL94V-0

Black

LCP Beige

Black

Crimp contacts Contact Phosphor bronze Tin plating or gold plating ---------

Dec.1.2019Copyright2019HIROSEELECTRICCO.,LTD.AllRightsReserved.

Downloaded from Arrow.com.Downloaded from Arrow.com.