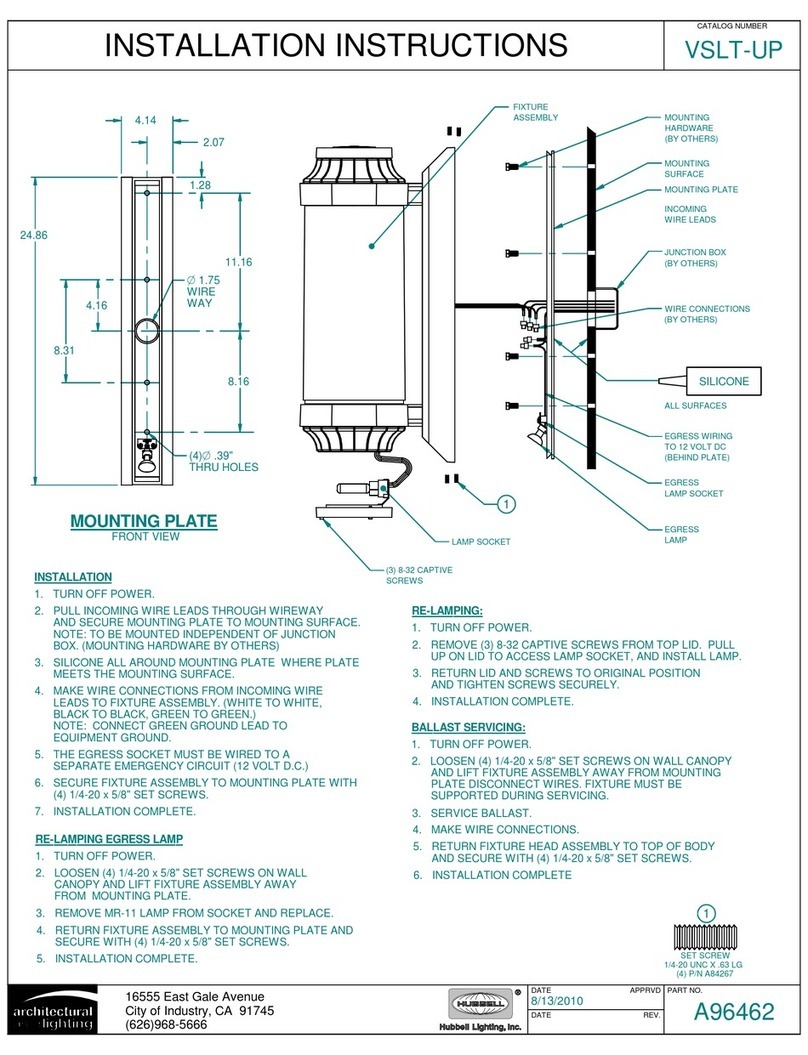

6. Connect remote lamps (if used) to blue (+, fused) and yellow (–) leads (10) (Fig.2orFig.3).

7. Connect120or277VACinputconnectionstotransformer(Fig.2orFig.3). Connect green wire to

building ground.

Note: insulate the unused transformer lead to prevent potential shock hazard.

Dependingonthetypeofunitbattery,followsteps8through16below.

•UnitsSuppliedWithLead-CalciumBatteries

8. Placebattery(8) into housing (2).

9. Determine proper battery orientation from Fig.2(singleharnessleadconnection).Batteryispositionedtotheleftofthecircuit

board.

10.Connectpositive(+,red)andnegative(–,yellow) battery harness leads from printed circuit board to corresponding battery

terminals as shown in Fig.2.

11. Check all wiring for loose or missing connections.

12.Replacecover.Tightencoverscrews.

13.Aimlamp heads (5) to properly illuminate the path of egress.

14.EnergizeunitwithACpower.

Note: Allow unit to charge for 24 hours prior to performing initial test.

15.Pressandholdthe“TEST”button(seeFig.2 for “TEST”buttonlocation)toconrmilluminationandproperaimingof

emergency lamps. (“AC ON” indicator LED should go off). Release the “TEST”button;emergencylampsshouldextinguish.

Normal operation begins.

16. Normal Operation: with power supplied, “AC ON” LED indicator is illuminated and emergency lamps are off.

•UnitsSuppliedWithNickelCadmiumBatteries

8. Placebattery(8) into housing (2).

9. Determine proper battery orientation from Fig.3(singleordoubleharnessleadconnections).Batteryispositionedtotheleftof

the circuit board.

10. Connect battery harness leads from printed circuit board to corresponding battery harness leads as shown in Fig.3.

11. Check all wiring for loose or missing connections.

12.Replacecover.Tightencoverscrews.

13.Aimlamp heads (5) to properly illuminate the path of egress.

14.EnergizeunitwithACpower.

Note: Allow unit to charge for 24 hours prior to performing initial test.

15.Pressandholdthe“TEST”button(seeFig.3 for “TEST”buttonlocation)toconrmilluminationandproperaimingof

emergency lamps. (“AC ON” indicator LED should go off). Release the “TEST”button;emergencylampsshouldextinguish.

Normal operation begins.

16. Normal Operation: with power supplied, “AC ON” LED indicator is illuminated and emergency lamps are off.

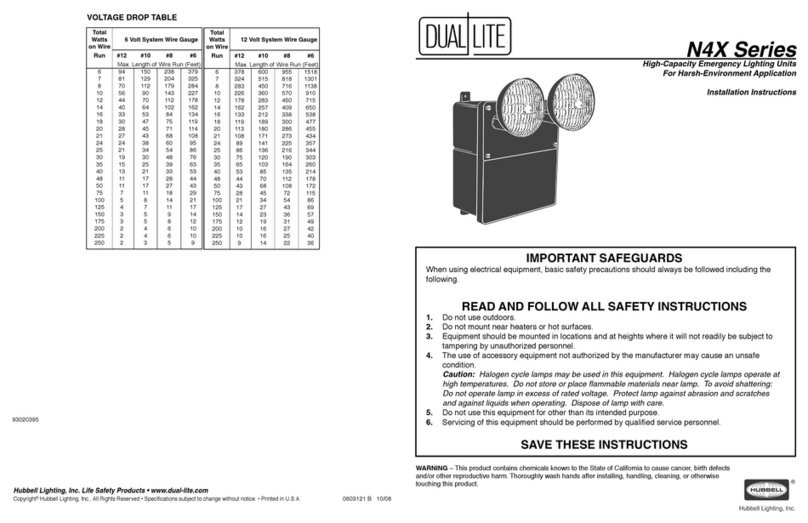

ROUTINE TEST CYCLING

1. Everythree(3)months:Iftherehasbeennopowerfailure,pressandholdthe“TEST”buttonforatleastthirty(30)secondsto

conrmemergencylampoperation.Release“TEST” button to return to battery charging mode.

2. Onceayear:Performafullbatteryconditioningcyclebyde-energizingtheACcircuittowhichtheunitisconnected,andallow

theunittooperateforninety(90)minutesonbatterypower.Followingsuccessfultest,energizeACcircuittobeginbattery

charging cycle.

REPLACING EMERGENCY LAMPS AND BATTERIES

General

a.De-energizetheACpowersupplytotheunit.

b.Removeenclosurecover.

c.Disconnectpositive(+,red)batterylead

(nickel cadmium models-disconnectbatteryandprintedcircuitboardconnectors).

•ReplacingUnitEmergencyLamp •ReplacingUnitBattery

1.Removediffuserlensfrom 1. Removedefectivebattery.Recycleresponsibly.

lamphousingbypryinglens ReplacewithgenuinePrescolitebattery.

adjacent to tab slot (see Fig.4) 2. Placenewbatteryinenclosure.Make

2.Removeandreplacelamp. connectionsfollowingstepsoutlinedabove.

(refer to unit product label 3. Test unit.

forspeciclamptype)

Fig.1

Fig.3 Single and Double Harness Lead

Connections

Nickel-CadmiumBatteryModels

Fig.2 Single Harness Lead Connection

Lead-CalciumBatteryModels

Fig.4