This unit is designed to be mounted on a wall or ceiling. Provide standard units witha single unswitched supply from

a 120VAC, 240VAC, or 277VAC branch circuit used for normal lightning in the area to be protected. For Spectron®

self-testing/self-diagnostic units, provide unit with 120VAC or 277VAC branch circuit.

The EV unit is equipped with intelligent wiring. Connect the black wire from the unit to the hot building wire

(120-277VAC) and the white wire to the neutral building wire.

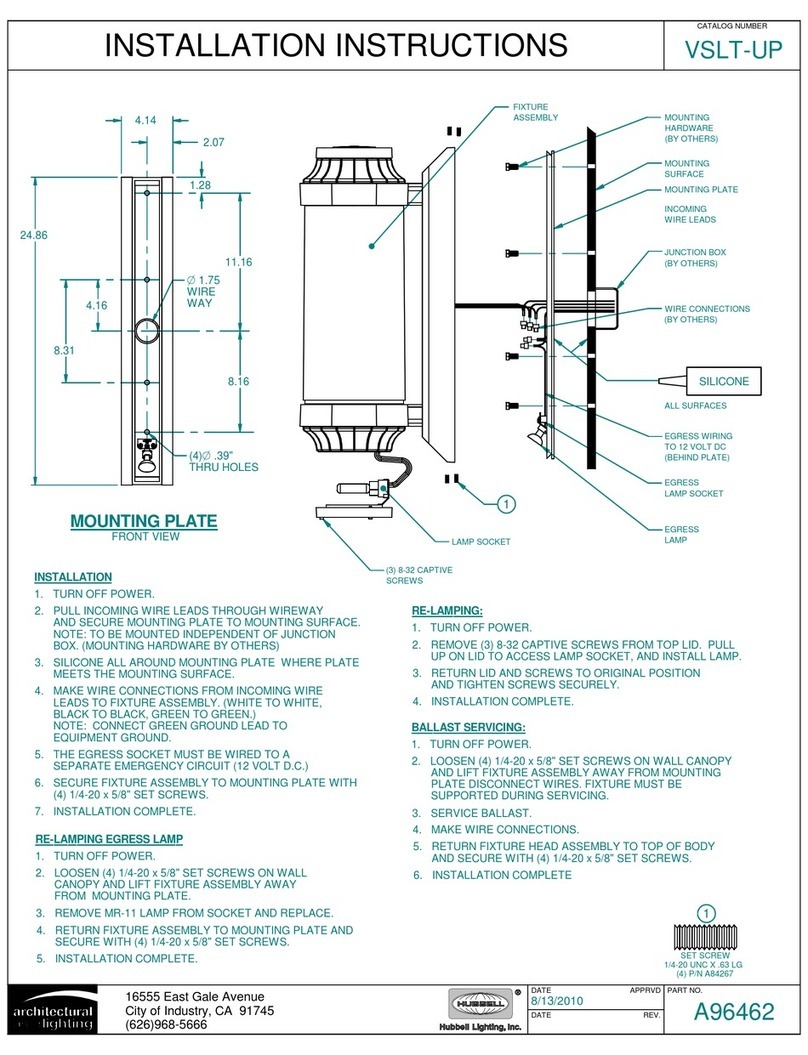

Wall or Ceiling Mount - Back Power Feed

1. Remove appropriate KO’s in backplate to

mount backplate to junction box.

2. Remove center KO from backplate and feed

suppply leads through.

3. Secure backplate to junction box.

4. To help with wiring, attach cover to backplate

with provided plastic hinge

5. Connect wires from the unit to the building

leads and secure with wire nuts.

6. Connect battery lead to circuit board header

as shown.

“AC ON” LED is illuminated when AC power is present.

NOTE: All models are supplied with an AC Lockout circuit, which prevents the emergency lights from illuminating

when the battery is connected and no AC power is present.

NOTE: All models are supplied with a Low Voltage Disconnect circuit, which prevents damage to the battery from

deep discharge during prolonged emergency operation.

NOTE: Batteries are often shipped in a discharged state - this is normal. The battery will require charging.Allow 24

hours of charging before testing the unit.

Models with SPECTRON® Self-Testing/Self-Diagnostic Circuitry

Models Equipped with the Spectron® self-testing/self-diagnostic electronics system provide:

•Visual indicatiioin ofAC power status •Visual indicatiion of self-diagnostic test status and results

--Visual indication of any unit malfunction include--

• Battery Disconnected • Battery Fault • Charger Fault • LED Driver Fault • Lamp Fault

Spectron equipped units also include:

Brownout protection: unit wll automatically transfer to emergency operation upon detection of low AC power

(approximately 80% of nominal line)

Dime Delay Retransfer: upon return of normal AC power, unit will remain in emergency mode for an additional 15

minutes to allow AC power to stabalize.

** **

The Spectron® optioned EV4DI requires a load learn process at

installation. Press and hold the test button for more than 5 seconds

to initiate the load learn.

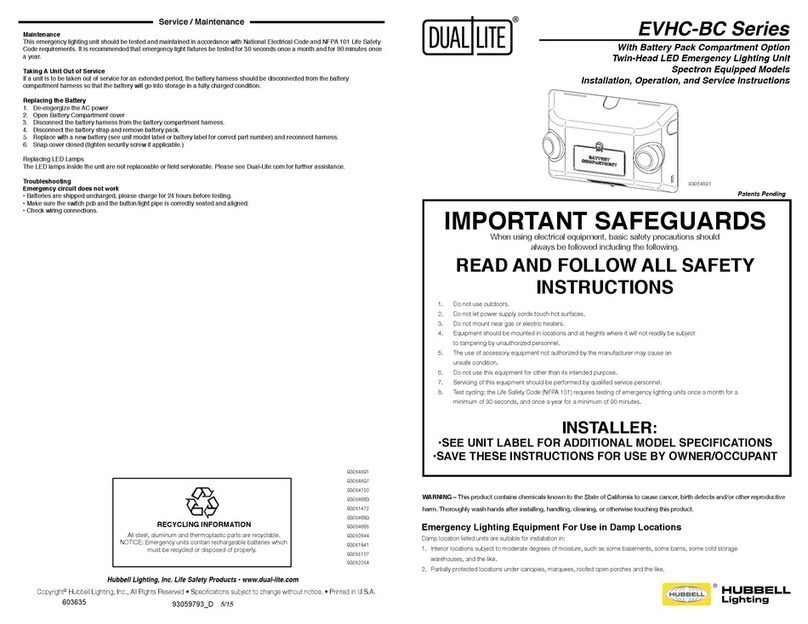

LED Status Indicator

A bicolor LED (green/red) is provided on the control

panel of all models equipped with the Spectron® option.

Green Operating Status LED:

The green Operating Status LED serves as both

an AC power and self-test indicator. During normal

operation, the green Operating Status LED will be

illuminated, indicating the presence of AC power. During

all automatic or manual self-test cycles, the green

Operating Status LED will blink twice every second.

Red Service Alert LED:

Under normal operating conditions, the red Service Alert

LED indicator will remain off. If the Spectron® controller

detects a malfunction, the red Service Alert LED will

blink in the pattern listed in the following table:

Red Status LED Code Description

One Blink: ON/Pause Battery Disconnected

Two Blinks: ON/Pause Battery Fault

Three Blinks: ON/Pause Charger Fault

Four Blinks: ON/Pause LED Driver fault

Five Blinks: ON/Pause Lamp Fault

Red/Green Alternating Load Learn in Process

Automatic Tests.

The unit will automatically initiate a self-test/self-

diagnostic cycle based on the following table:

Testing Period Duration of Test

Once a month 1 minute

Once every 6 months Alternating: 30 minutes or

60 minutes

Note: After clearing a 5 blink lamp fault by initiating

a load learn test, a 60 second manual test must be

initiated.

Manual Tests

Using the unit test switch, users can initiate different

duration test cycles based on the following table:

Initiating Action Test Cycle

Press test switch once 1 minute

Press test switch twice 90 minutes

Pressing the test switch any time after a 90 min. test

cycle has begun cancels the remainder of the 90 min.

test and returns the unit to normal operation.

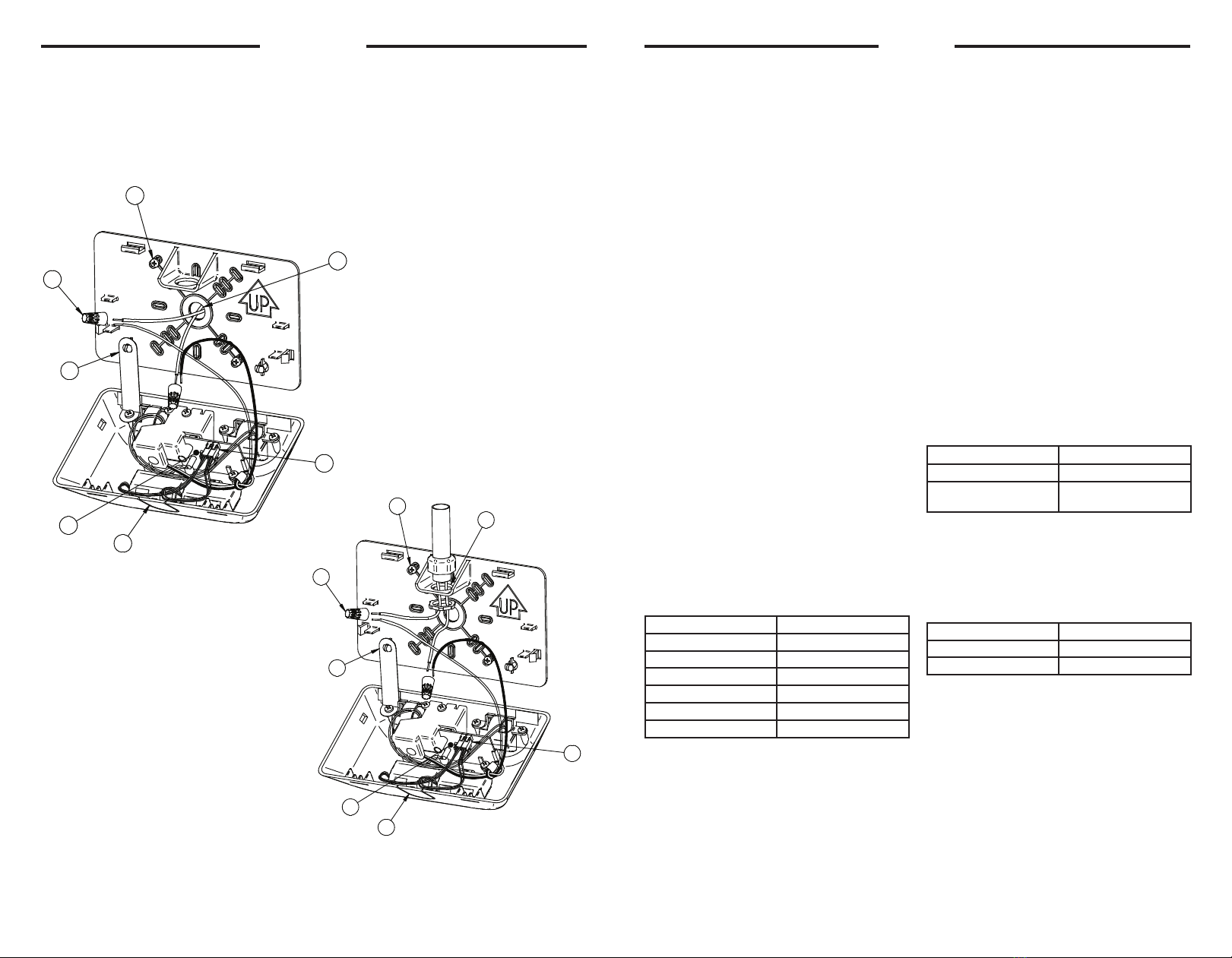

Wall Mount - Surface Wiring (Top Power Feed Only)

1. Remove appropriate KO’s in backplate to mount

backplate to junction box.

2. Feed wires through and secure conduit to backplate

3. Remove the breakout on top of the housing.

4. To help with wiring, attach cover to backplate with

provided plastic hinge.

5. Connect wires form the unit to the building leads and

scure with wire nuts.

6. Connect bettery lead to circuit board header as

shown.

INSTALLATION Operation

12

1

B

A

B

2

A

This document contains confidential and proprietary information of Dual Lite.

Receipt or possession of this document does not convey any rights to

reproduce or disclose its contents, or to make, use , or sell anything it may

disclose. Reproduction, disclosure, or use of the document or its contents,

without the specific written authorization of Dual Lite, may violate the

intellectual property rights of Dual Lite.

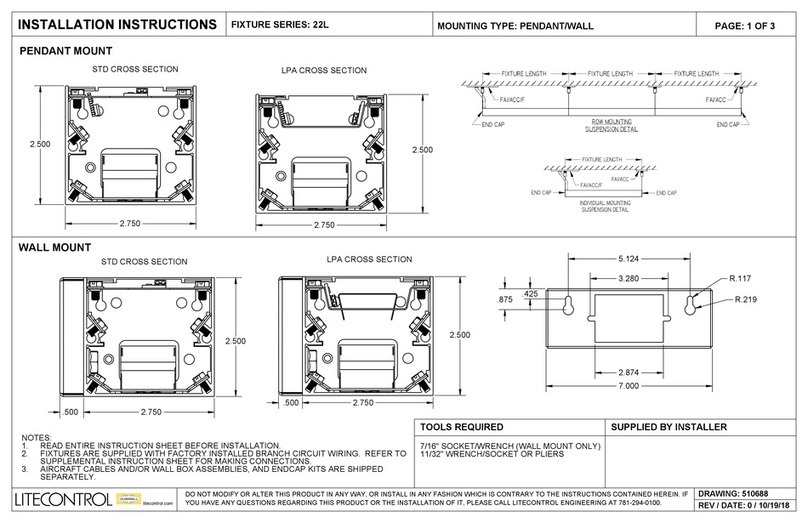

CRITICAL DIMENSIONS

UNSPECIFED TOLERANCES: INCHES

X.X=

0.02 X.XX=

0.01 X.XXX=

0.005

FRACTIONS=

1/32 ANGULAR TOLERANCE=

.5

REV.

PART NO.FINISH:MATERIAL:

THIRD ANGLE PROJECTION

DRAWN:

DO NOT SCALE PRINT

CONFORMS TO ASME Y14.5M

DIMENSIONS IN [ ] IN MM

DIMENSIONS IN INCHES

CHECKED BY:

ENGINEERING:

CATALOG NO. SCALE

A

SIZE DRAWING NO.

SHT 1

1 SHTS

------

93099188

93099188

A

ILL-INST EV UNIT -02WAL INST1

JEB 6/28/2018

JEB 06/28/18

EC 171030003

JEB 06/28/18

1:2

5

4

2

1

6

3

7

12

1

B

A

B

2

A

This document contains confidential and proprietary information of Dual Lite.

Receipt or possession of this document does not convey any rights to

reproduce or disclose its contents, or to make, use , or sell anything it may

disclose. Reproduction, disclosure, or use of the document or its contents,

without the specific written authorization of Dual Lite, may violate the

intellectual property rights of Dual Lite.

CRITICAL DIMENSIONS

UNSPECIFED TOLERANCES: INCHES

X.X=

0.02 X.XX=

0.01 X.XXX=

0.005

FRACTIONS=

1/32 ANGULAR TOLERANCE=

.5

REV.

PART NO.FINISH:MATERIAL:

THIRD ANGLE PROJECTION

DRAWN:

DO NOT SCALE PRINT

CONFORMS TO ASME Y14.5M

DIMENSIONS IN [ ] IN MM

DIMENSIONS IN INCHES

CHECKED BY:

ENGINEERING:

CATALOG NO. SCALE

A

SIZE DRAWING NO.

SHT 1

1 SHTS

------

93099189

93099189

A

ILL-INST EV UNIT -02WAL INST2

JEB 6/28/2018

JEB 06/28/18

EC 171030003

JEB 06/28/18

1:2

5

4

2

1

6

3

7

93099189

93099188