1

2

2

4

5

6

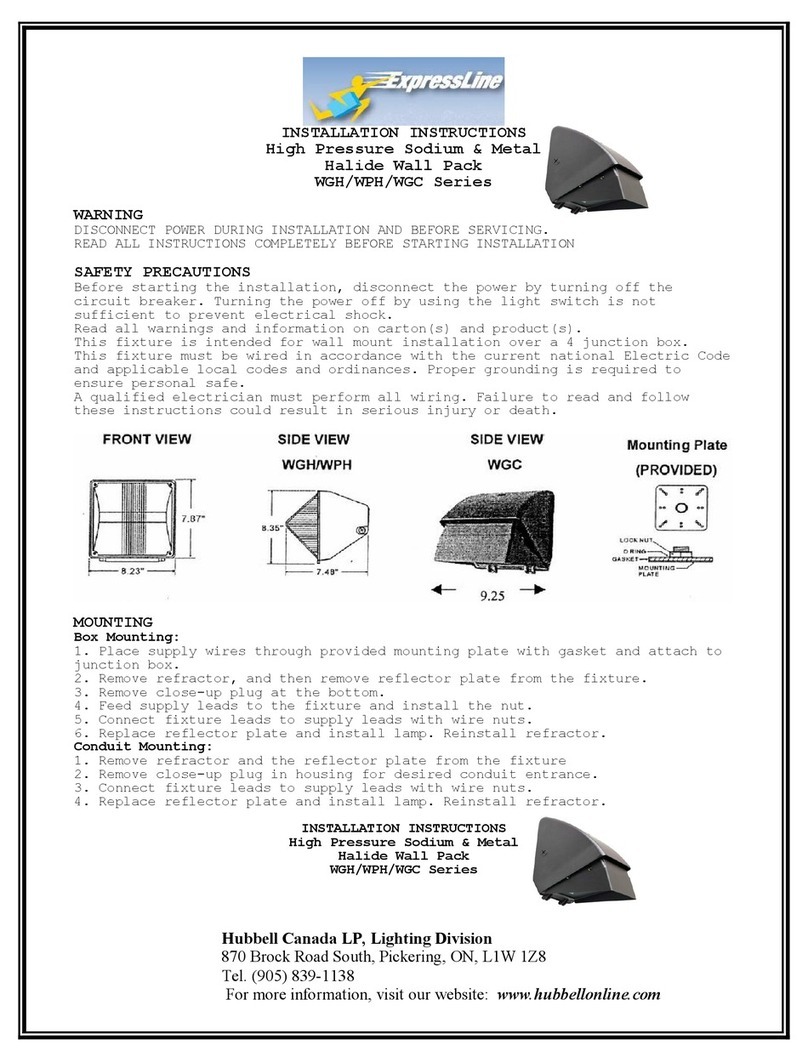

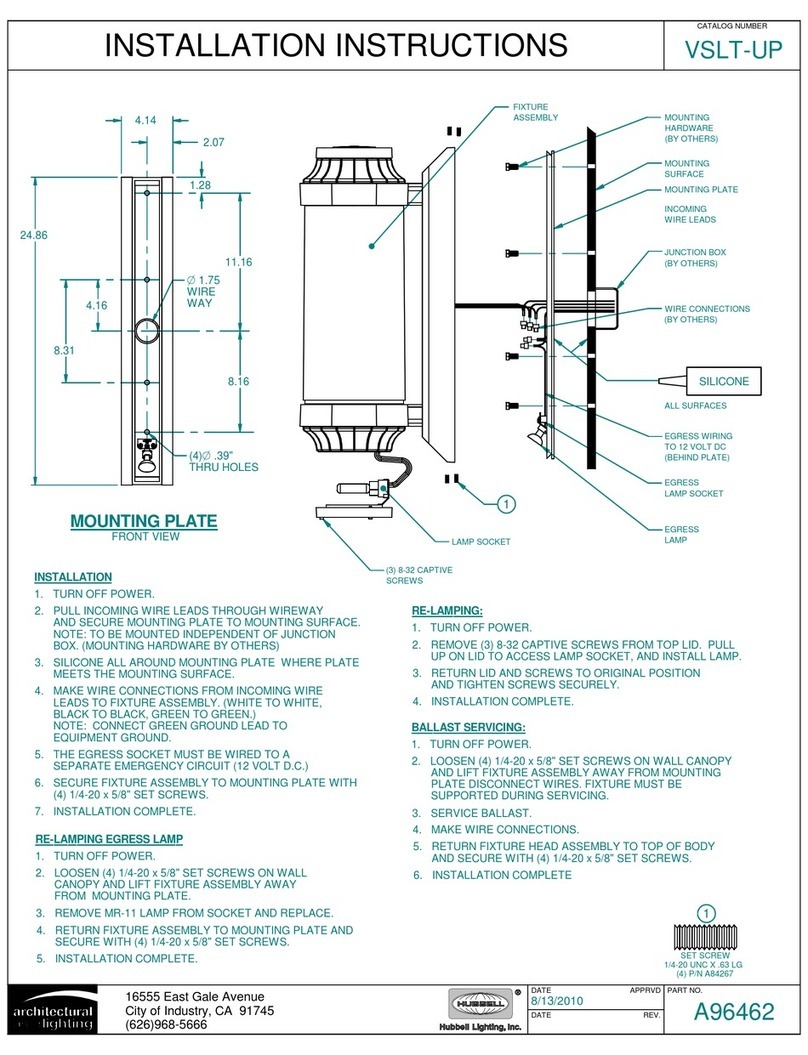

INSTALLATION INSTALLATION

The EVHC Spectron unit is equipped with intelligent wiring. Connect the black wire from the

unit to the hot building wire (120 or 277VAC) and the white wire to the building com wht wire.

1. Remove appropriate KO’s in backplate to mount

backplate to junction box.

2. Remove center KO from backplate and feed supply

leads through.

3. Secure back plate to junction box.

4. Connect wires from the unit to the building leads and

secure with wire nuts.

5. For remote EVHC models, cut the orange connector

from both remote leads and strip ends ½inch.

Observe proper polarity when connecting remote

leads to remote xtures. Pos. (+) to red remote xture

lead and Neg. (-) to black remote xture lead.

6. Installer should now become familiar with the eyeball

aimability and its limitations.

#6 Thread forming screw provided

This unit is designed to be mounted on a wall. Provide Spectron® self-testing/self-diagnostic units, with a single unswitched supply

from a 120 or 277 VAC branch circuit for normal lighting in the area to be protected.

1. Remove appropriate KO’s in back plate and mount

backplate to wall.

2. Afx conduit to backplate using correct hardware.

(Note: 3 mounting points)

3. Remove appropriate K.O.’s on housing.

4. Connect wires from the unit to the building leads and

Secure with wire nuts.

5. For remote EVHC models, cut the orange connector

from both remote leads and strip ends ½inch.

Observe proper polarity when connecting remote

leads to remote xtures. Pos. (+) to red remote xture

lead and Neg. (-) to black remote xture lead.

6. Installer should now become familiar with the eyeball

aimability and its limitations.

1. Align housing slots over tabs on backplate.

2. Pivot housing and snap closed.

3. Aim the lamps. Do not press on the lenses.

4. Connect battery pack harness to unit battery

compartment harness.

Wall Mount – Wiring

When opening battery compartment

cover, remove security screw

and pull open.

After mounting unit to wall.

Wall Mount – Conduit Wiring

Installing the Unit: Final Assembly

93054597

93054700

93055107

93051472

93054683 93054665

1

4

5

6

4

4

93052054

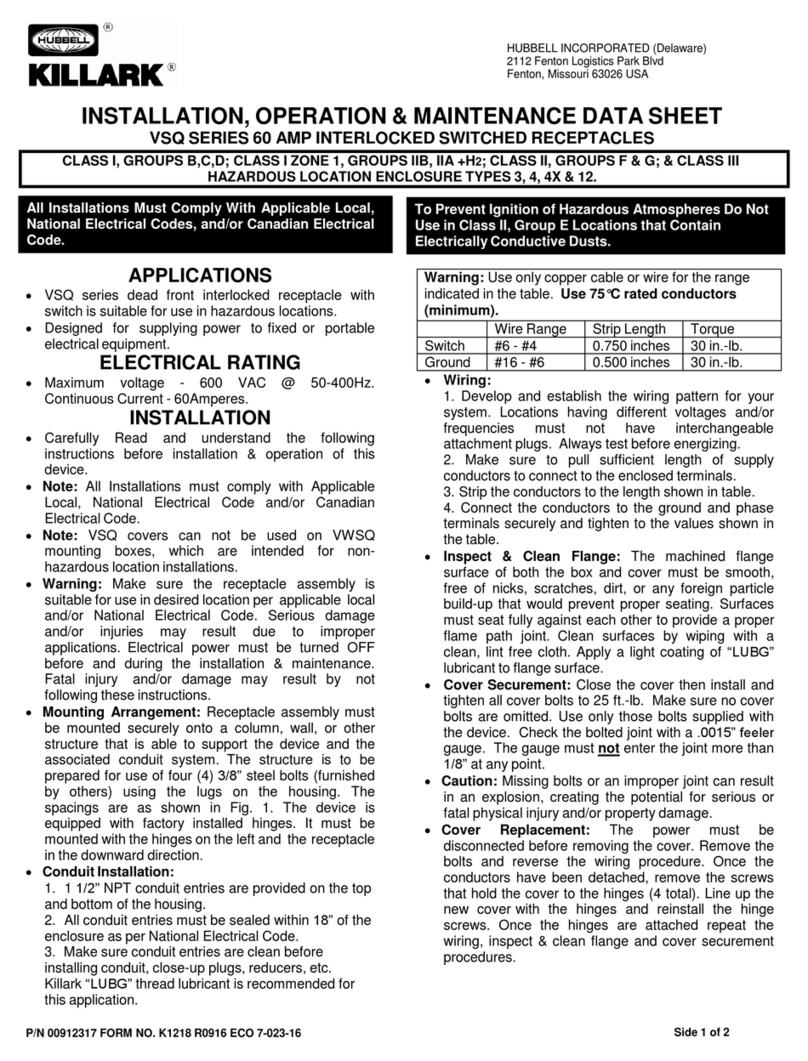

Initiating Action Test Cycle

Press test switch once 1 minute

Press test switch twice 90 minutes

Manual Tests

Using the unit test switch, users can initiate different

duration test cycles based on the following table:

Pressing the test switch any time after a 90 minute test

cycle has begun cancels the remainder of the 90 minute

test and returns the unit to normal operation.

Testing Period Duration of Test

Once a month 1 minute

Once every Alternating:

6 months 90 minutes or 60 minutes

Automatic Tests

The unit will automatically initiate a self-test/self-diagnostic

cycle based on the following table:

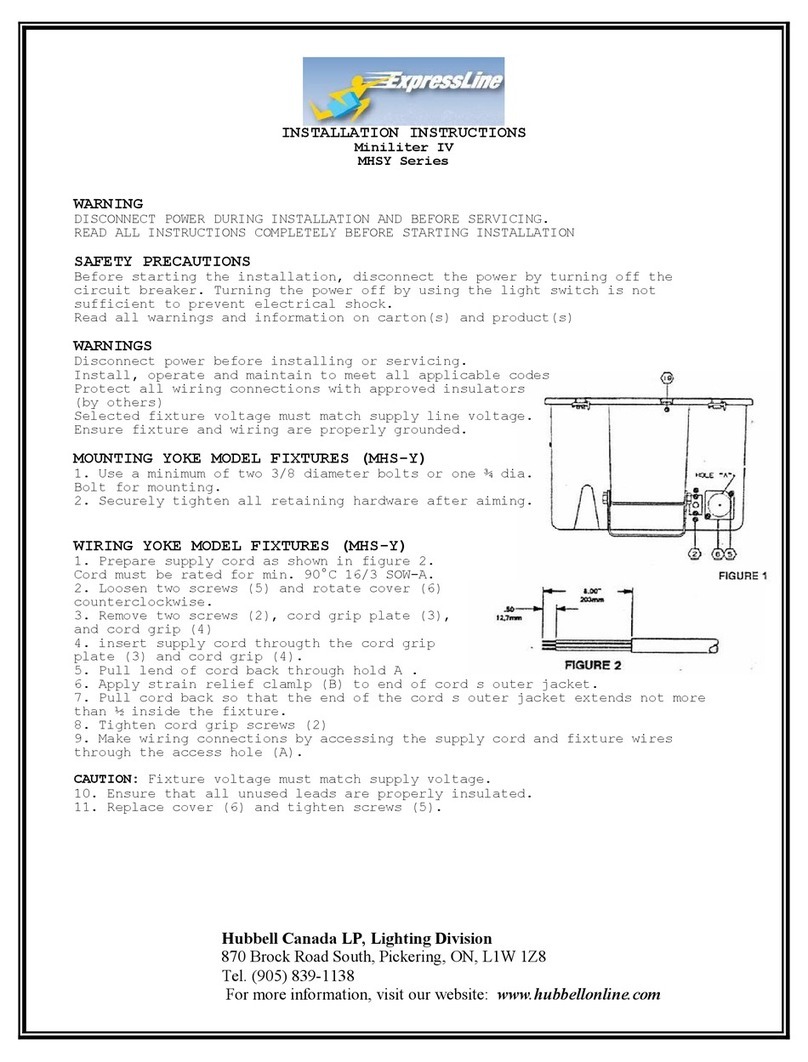

LED Status Indicator

A green/red LED is provided on the control panel

of all models equipped with the Spectron option.

Green Operating Status LED:

The green Operating Status LED serves as both an AC

power and self-test indicator. During normal operation,

the green Operating Status LED will be illuminated,

Indicating the presence of AC power. During all automatic

or manual self-test cycles, the green Operating

Status LED will blink twice every second.

Red Service Alert LED:

Under normal operating conditions, the red Service Alert

LED indicator will remain off. If the Spectron controller

detects a malfunction, the red Service Alert LED will blink

in the pattern listed on the label around the test button.

= LAMP FAULT

= LED DRIVER FAULT

= CHARGER FAULT

= BATTERY FAULT

= BATTERY DISCONNECTED

SERVICE ALERT CODES

ALTERNATING = LOAD LEARN IN PROGRESS

= LOAD LEARN FAILURE

***Once remote capacity models have been installed, press and hold the test button for

more than 5 seconds to initiate the “LOAD LEARN” process.***

“AC ON” LED is illuminated when AC power is present.

NOTE: All models are supplied with an AC Lockout circuit, which prevents the emergency lights from illuminating when the bat-

tery is connected and no AC power is present.

NOTE: All models are supplied with Low Voltage Disconnect circuit, which prevents damage to the battery from deep discharge

during prolonged emergency operation.

NOTE: Batteries are often shipped in a discharged state – this is normal. The battery will require charging. Allow 24 hours of

charging before testing the unit.

Models with Non-SPECTRON®Self-Diagnostic Circuitry.

Models equipped with Non-Spectron® self diagnostic electronics system provide:

• Visual indication of AC power status • Visual indication on self-diagnostic status and results.

Visual indication of any unit malfunctions include –

• Battery Disconnected • Charger Fault

Models with SPECTRON® Self-Testing/Self-Diagnostic Circuitry

Models equipped with the Spectron® self-testing/self-diagnostic electronics system provide:

• Visual indication of AC power status • Visual indication on self-diagnostic test status and results

Visual indication of any unit malfunctions include –

• Battery Disconnected • Battery Fault • Charger Fault • LED Driver Fault • Lamp Fault • Load Learn Failure

OPERATION

Spectron equipped units also include:

Browout protection: Unit will automatically transfer to emergency operation upon detection of low AC power

(approximately 80% of nominal line.)

Time Delay Retransfer: upon return of normal AC power, unit will remain in emergency mode for an additional 15 minutes

to allow AC power to stabilize.