• Belt Alignment

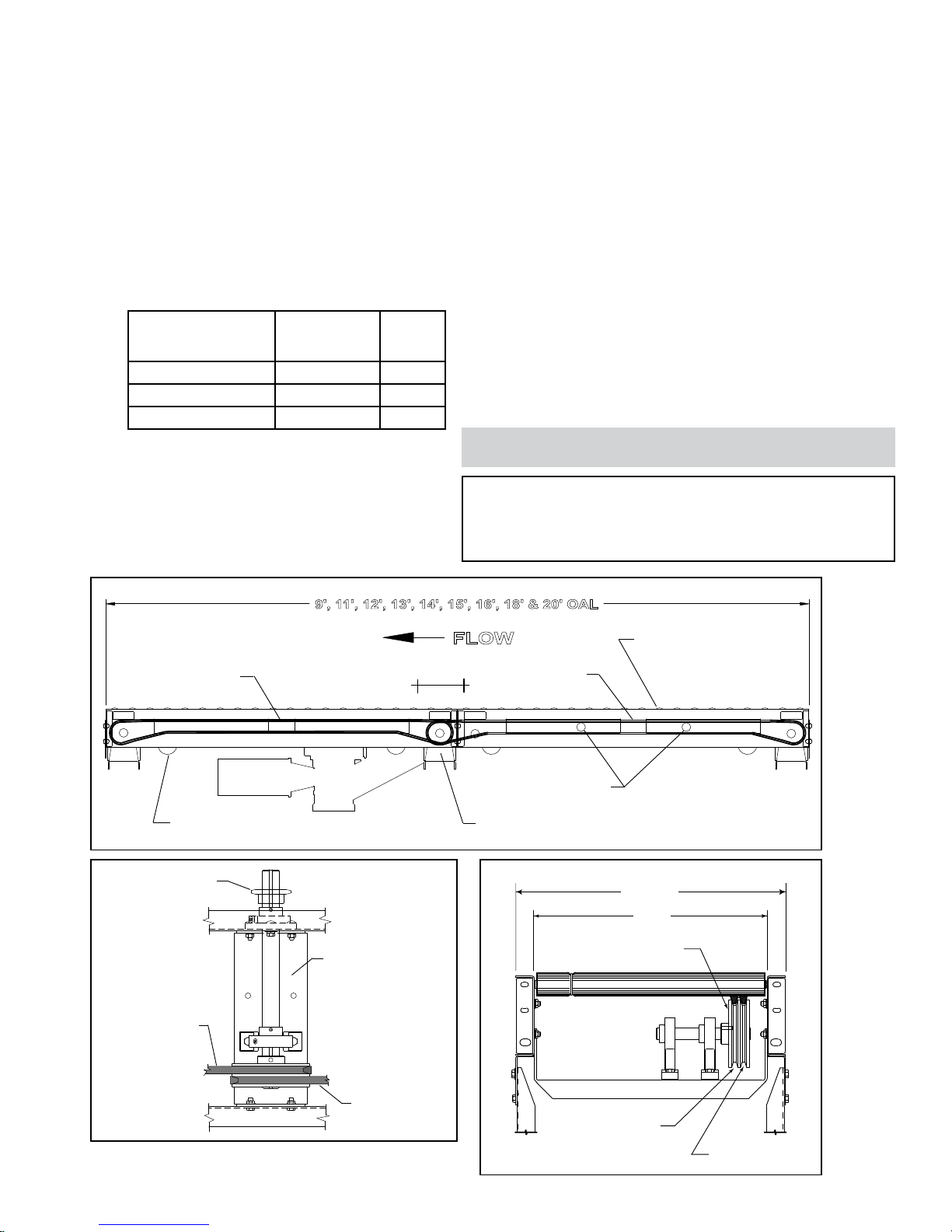

190-LRC 90°

1. It is critical to align both idler sheaves with the drive sheaves so the belt

runs in the middle of the drive sheave to prevent belt wear.

2. Position a straight edge on the face of the drive sheave (on the bearing

side).

3. Move each idler sheave until the belt is parallel with the straight edge.

190-LRC 60°, 45°, and 30°

1. It is critical to align both idler sheaves with the drive sheaves so the belt

runs in the middle of the drive sheave to prevent belt wear.

2. Position a straight edge on the face of the drive sheave (on the channel

side).

3. Move each idler sheave until the belt is parallel with the straight edge.

• Racked Sections

It is important that each bed section be checked for a “racked” or out-of-

square condition. If conveyor is not square, tracking problems will result.

Figure 6B indicates a racked section.

TO CORRECT AN OUT-OF-SQUARE SECTION

1. Locate points on corners of section and measure distance “A” & “B”. If the

dimensions are not equal, the section will need to be squared. (Figure 6C).

2. Use crossbracing supplied on underside of conveyor to square each

section. Adjust turnbuckle until Dimensions “A” & “B” are equal.

3. After all bed sections have been checked and corrected for “racked

condition”, tighten all butt couplings and pivot plate bolts.

4. Make final check to see that all conveyor sections are level across width

and length. If entire conveyor is level, supports can be lagged to floor.

• Electrical Equipment

CONTROLS

Electrical Code: All motor controls and wiring shall conform to the National

Electrical Code (Article 670 or other applicable articles) as published by

the National Fire Protection Association and as approved by the American

Standards Institute, Inc.

CONTROL STATIONS

A) Control stations should be so arranged and located that the operation of

the equipment is visible from them, and shall be clearly marked or labeled to

indicate the function controlled.

B) A conveyor which would cause injury when started shall not be started

until employees in the area are alerted by a signal or by a designated person

that the conveyor is about to start.

When a conveyor would cause injury when started and is automatically

controlled or must be controlled from a remote location, an audible device

shall be provided which can be clearly heard at all points along the conveyor

where personnel may be present. The warning device shall be actuated by

the controller device starting the conveyor and shall continue for a required

period of time before the conveyor starts. A flashing light or similar visual

warning may be used in conjunction with or in place of the audible device if

more effective in particular circumstances.

Where system function would be seriously hindered or adversely

affected by the required time delay or where the intent of the warning may

be misinterpreted (i.e., a work area with many different conveyors and allied

devices), clear, concise, and legible warning shall be provided. The warning

shall indicate that conveyors and allied equipment may be started at any time,

that danger exists, and that personnel must keep clear. The warnings shall be

provided along the conveyor at areas not guarded by position or location.

C) Remotely and automatically controlled conveyors, and conveyors where

operator stations are not manned or are beyond voice and visual contact from

drive areas, loading areas, transfer points, and other potentially hazardous

locations on the conveyor path not guarded by location, position, or guards,

shall be furnished with emergency stop buttons, pull cords, limit switches, or

similar emergency stop devices.

All such emergency stop devices shall be easily identifiable in the

immediate vicinity of such locations unless guarded by location, position, or

guards. Where the design, function, and operation of such conveyor clearly is

not hazardous to personnel, an emergency stop device is not required.

The emergency stop device shall act directly on the control of the

conveyor concerned and shall not depend on the stopping of any other

equipment. The emergency stop devices shall be installed so that they cannot

be overridden from other locations.

D) Inactive and unused actuators, controllers, and wiring should be removed

from control stations and panel boards, together with obsolete diagrams,

indicators, control labels, and other material which serve to confuse the

operator.

SAFETY DEVICES

A) All safety devices, including wiring of electrical safety devices, shall be

arranged to operate in a “Fail-Safe” manner, that is, if power failure or failure

of the device itself would occur, a hazardous condition must not result.

B) Emergency Stops and Restarts. Conveyor controls shall be so arranged

that, in case of emergency stop, manual reset or start at the location where

the emergency stop was initiated, shall be required of the conveyor(s) and

associated equipment to resume operation.

C) Before restarting a conveyor which has been stopped because of an

emergency, an inspection of the conveyor shall be made and the cause of

the stoppage determined. The starting device shall be locked out before

any attempt is made to remove the cause of stoppage, unless operation is

necessary to determine the cause or to safely remove the stoppage.

Refer to ANSI Z244.1-1982, American National Standard for Personnel

Protection – Lockout/Tagout of Energy Sources – Minimum Safety

Requirements and OSHA Standard Number 29 CFR 1910.147 “The Control

of Hazardous Energy (Lockout/Tagout).”

WARNING! Electrical controls shall be installed and wired by a qualified

electrician. Wiring information for the motor and controls are furnished by

the equipment manufacturer.

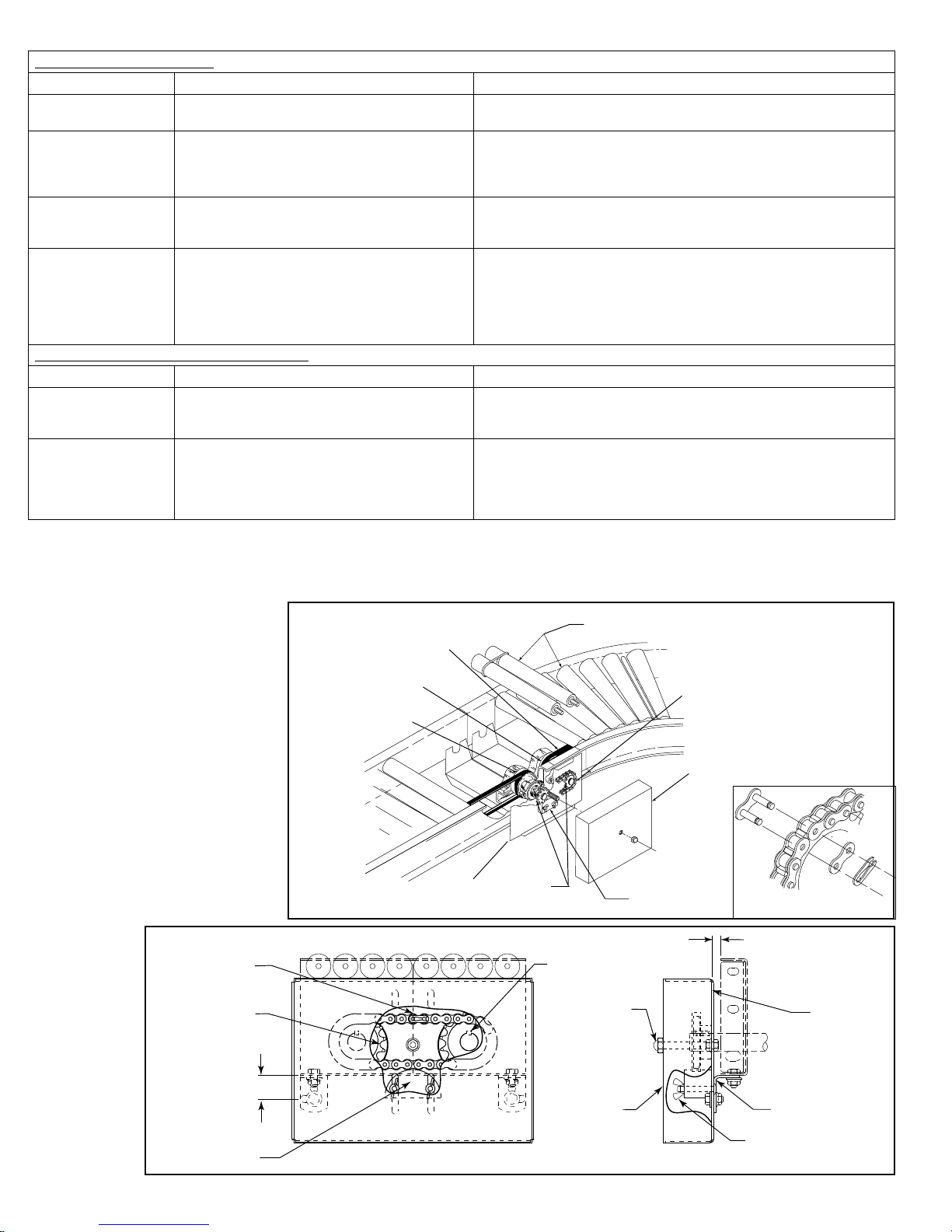

1. IT IS CRITICAL TO ALIGN BOTH IDLER SHEAVES WITH THE DRIVE

SHEAVES SO THE BELT RUNS IN THE MIDDLE OF THE DRIVE SHEAVE

TO PREVENT BELT WEAR.

2. POSITION A STRAIGHT EDGE ON THE FACE OF THE DRIVE SHEAVE

(ON THE CHANNEL SIDE).

3. MOVE EACH IDLER SHEAVE UNTIL THE BELT IS PARALLEL WITH THE

STRAIGHT EDGE.

NOTES FOR 60, 45 AND 30 DEGREE:

STRAIGHT EDGE

(BORDE RECTO)

IDLER

SHEAVE

(POLEA TENSORA)

DRIVE

SHEAVE

(POLEA

MOTRIZ)

NOTES FOR 90 DEGREE:

1. IT IS CRITICAL TO ALIGN BOTH IDLER SHEAVES WITH THE DRIVE

SHEAVES SO THE BELT RUNS IN THE MIDDLE OF THE DRIVE SHEAVE

TO PREVENT BELT WEAR.

2. POSITION A STRAIGHT EDGE ON THE FACE OF THE DRIVE SHEAVE

(ON THE BEARING SIDE).

3. MOVE EACH IDLER SHEAVE UNTIL THE BELT IS PARALLEL WITH THE

STRAIGHT EDGE.

DRIVE SHEAVE

(POLEA MOTRIZ)

IDLER

SHEAVE

(POLEA TENSORA)

STRAIGHT EDGE

(BORDE RECTO)

FIGURE 6A

1. IT IS CRITICAL TO ALIGN BOTH IDLER SHEAVES WITH THE DRIVE

SHEAVES SO THE BELT RUNS IN THE MIDDLE OF THE DRIVE SHEAVE

TO PREVENT BELT WEAR.

2. POSITION A STRAIGHT EDGE ON THE FACE OF THE DRIVE SHEAVE

(ON THE CHANNEL SIDE).

3. MOVE EACH IDLER SHEAVE UNTIL THE BELT IS PARALLEL WITH THE

STRAIGHT EDGE.

NOTES FOR 60, 45 AND 30 DEGREE:

STRAIGHT EDGE

(BORDE RECTO)

IDLER

SHEAVE

(POLEA TENSORA)

DRIVE

SHEAVE

(POLEA

MOTRIZ)

NOTES FOR 90 DEGREE:

1. IT IS CRITICAL TO ALIGN BOTH IDLER SHEAVES WITH THE DRIVE

SHEAVES SO THE BELT RUNS IN THE MIDDLE OF THE DRIVE SHEAVE

TO PREVENT BELT WEAR.

2. POSITION A STRAIGHT EDGE ON THE FACE OF THE DRIVE SHEAVE

(ON THE BEARING SIDE).

3. MOVE EACH IDLER SHEAVE UNTIL THE BELT IS PARALLEL WITH THE

STRAIGHT EDGE.

DRIVE SHEAVE

(POLEA MOTRIZ)

IDLER

SHEAVE

(POLEA TENSORA)

STRAIGHT EDGE

(BORDE RECTO)

6