Black—Standard prox output lead. This lead provides a 24VDC (high) signal each

time the prox detects a divert shoe. This is an optional output and is to be used at

the discretion of the controls provider.

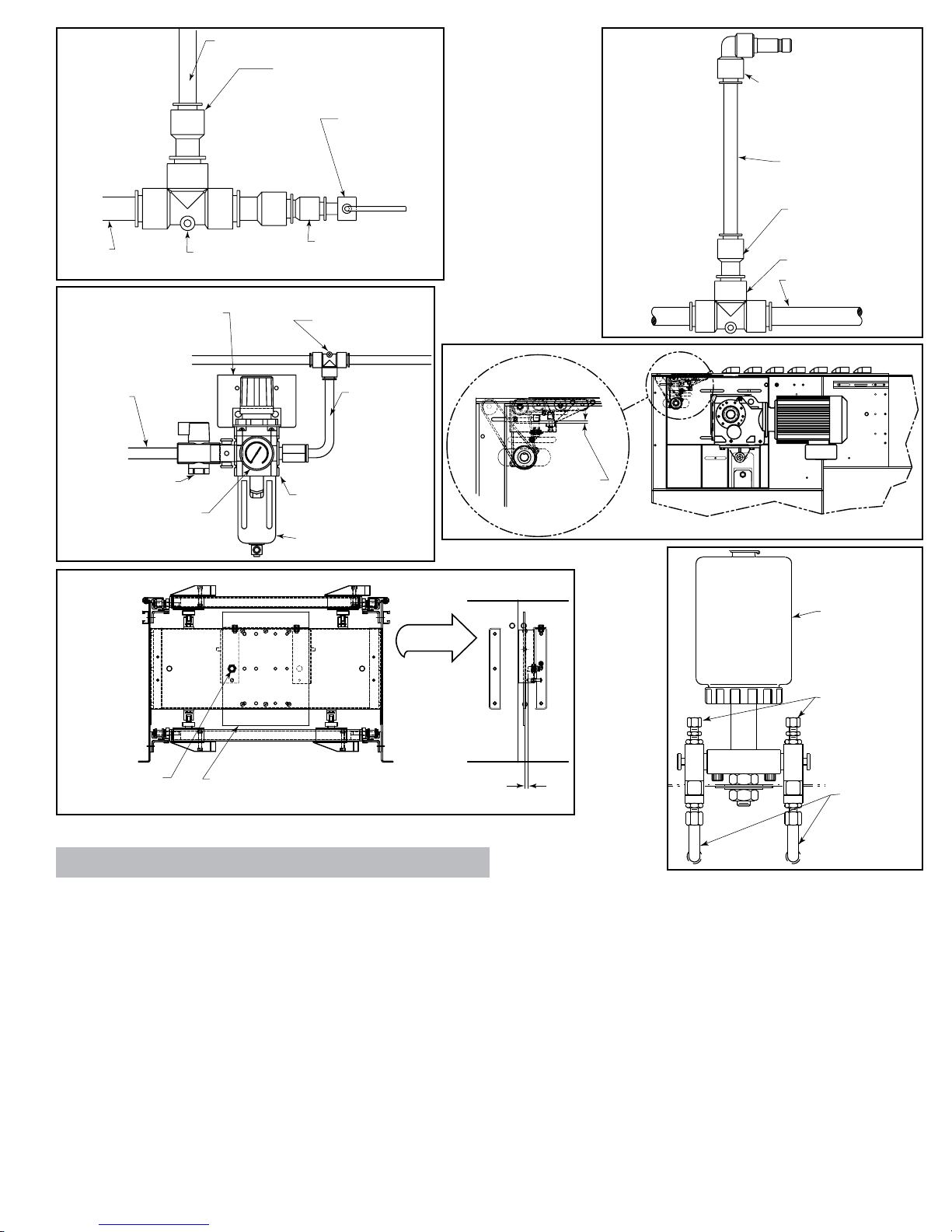

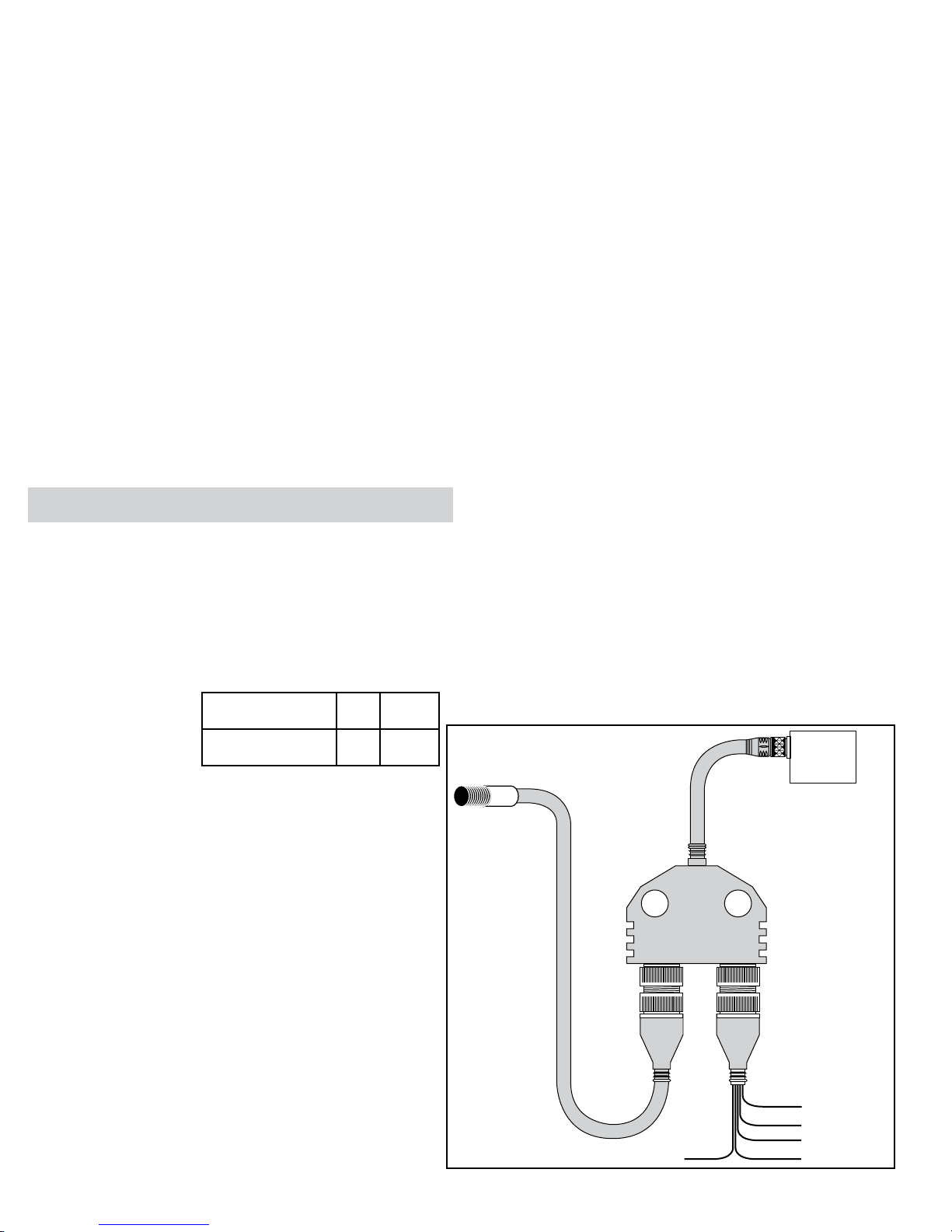

HIGH-SPEED SOLENOID AIR VALVE

The solenoid air valve is used to receive the smart prox output signal and provide

air to the proper end of the divert switch cylinder to move and hold the switch in

either the “home” or “divert” positions. The valve used is specially designed for the

high speed operation necessary for proper divert switch timing.

The two inputs of the solenoid are non-polarized, allowing either lead to be used as

input or ground for the valve. The solenoid requires 24VDC, 4W to operate.

The solenoid air valve is controlled directly by the smart prox. Direct control of this

valve by the controls package is not required or advised.

Other Control Components Supplied with the Conveyor

VARIABLE FREQUENCY DRIVE CONTROLLER

The variable frequency drive (VFD) is a motor controller that has three functions:

1. It provides a smooth acceleration of the drive motor, allowing the sorter to slowly

“ramp up” to full speed. This protects the sorter components from the stress of a

full-speed start up.

2. It allows the speed of the sorter to be adjusted to match speed requirements of

the system. Also, it allows the sorter to be operated at a very slow speed during

installation “Debugging” and when certain mechanical components are checked

after servicing.

3. It allows the sorter to be operated at a slower speed during “off-peak” seasons,

reducing energy consumption, noise, and wear.

Refer to the VFD manufacturer’s installation manual, provided with the sorter, for

wiring and adjustment instructions.

AIR PRESSURE SWITCH

The air pressure switch (Fig. 5A) is used to detect low operating air pressure.

Operation of the sorter at air pressures under 50 PSI can cause erratic switching

and potential switch damage. If air pressure falls below this level, the sorter must

be shut down until the cause of the pressure drop has been found and remedied.

The pressure switch provides a contact-type output which closes at pressures at

or above about 48 PSI and opens below that air pressure. The system controls

provider should use this switch to monitor air pressure at the sorter and should shut

down the sorter if an open (low) output is detected from the pressure switch.

Refer to the pressure switch manufacturer’s installation manual, provided with the

sorter, for wiring instructions.

SAFETY PROXIMITY SWITCHES

There are safety switch devices located at various locations in the sorter to indicate

when a divert shoe is out of place, an obstruction has entered the sorter, or when

some other event has occurred that could cause damage to the sorter or danger to

personnel. These safety switches use normal inductive proximity switches as the

electrical interface to the system controls.

There are two types of safety switches in the sorter:

1. Shoe position safety switches are switch mechanisms inside the sorter that trip

if a divert shoe passes them that is not in its proper track. They are also used to

detect foreign objects that might fall between the slats and enter the interior of the

sorter. They are made to detect problems on both the upper and return portions

of the sorter.

There is one shoe position safety switch located at the infeed end and one at the

discharge end of the sorter. There are additional switches included for every 30

feet of sorter length after the first 30 feet. For example, a sorter 50 feet long will

have a total of 3 switches, a sorter 80 feet long will have a total of 4 switches and

so on. These additional switches are spaced evenly along the sorter’s length.

2. The pop-up transition roller safety switch is used to detect when the transition

rollers on the discharge end of the sorter are in the “up” position. These rollers are

designed to pop up if a stray divert shoe or a foreign object makes contact with

them.

The normal state of the output of the safety proximity switch is”on” (high). If a switch

detects a problem the signal is changed to “off” (low). The system controls must

be configured to go to an “emergency stop” condition and shut down the sorter

and related equipment when a problem is detected. Restart must not be possible

until the problem is corrected and the safety switch that detected the problem is

again “on” (high).

Refer to the proximity switch manufacturer’s installation manual, provided with the

sorter, for wiring instructions.

CATENARY TAKE-UP PHOTO EYE

The catenary take-up photo-eye monitors the amount of chain sag occurring in

the drive’s catenary area. The photo-eye is a retro-reflective, light-operated type,

positioned in the catenary so that if the carrying chains allow the slats to sag below

a certain level, the beam of the eye is blocked.

The system controls must be configured to stop the sorter when the photo-eye

beam is blocked (photo-eye output is “off” or “low”) and provide an indication to

the sorter operator that the chains must be taken up or shortened before operating

the sorter further.

Refer to the photo-eye manufacturer’s installation manual, provided with the sorter,

for wiring instructions.

ENCODER

An encoder is included with the sorter to provide a pulse signal to be used for

product tracking. The encoder provides a square-wave pulse signal of 30 pulses

per revolution of the sorter infeed shaft. This equates to one pulse for every 1.75

inches of sorter travel.

The encoder requires 24VDC power, and provides a 24VDC pulse output.

Refer to the encoder manufacturer’s installation manual provided with the sorter,

for wiring instructions.

CHAIN OILER SOLENOID

The chain oiler is used to provide automatic lubrication of the carrying chains

during sorter operation. When the oiler solenoid valve is energized, oil is allowed

to gravity feed from the oiler reservoir, through metering valves, to brushes located

above the return chains in the sorter.

The system controls should be configured to activate the chain oiler solenoid for a

duration equal to one complete revolution of the carrying chains about every two

hours of operation. The actual amount of oil applied to the chains is controlled by

the metering screws (see “Conveyor Set-up” section of this manual). The chain

oiler solenoid requires 24VDC power to operate.

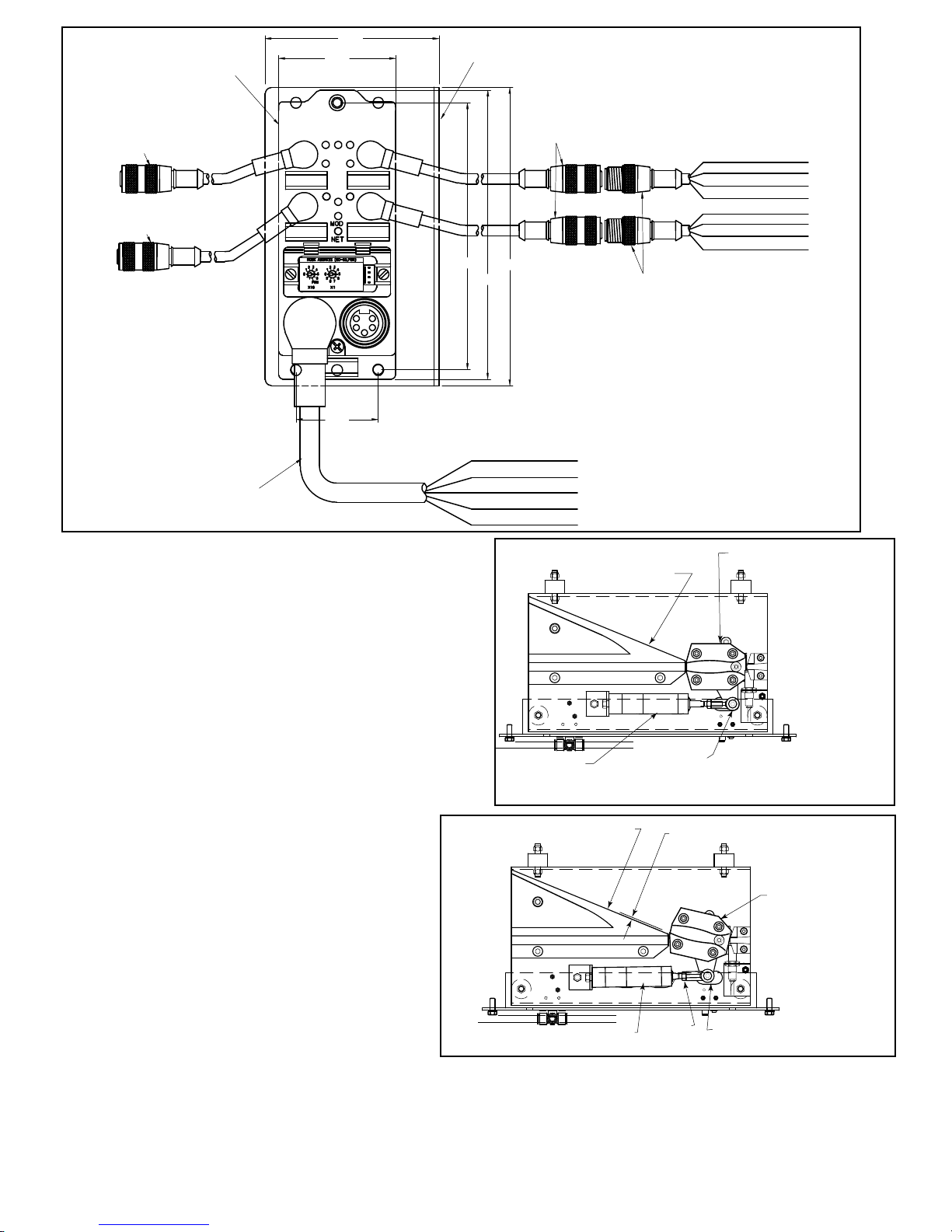

LOST BEARING DETECTION

The missing bearing block is used to detect a bearing missing from a divert shoe.

A divert shoe that does not have a bearing on the bottom can cause damage to

the sorter. The missing bearing block uses two proximity switches located in the

return section of the sorter to detect the presence of a bearing on the shoe. If one

prox detects a bearing being present but the other does not, the block removes

its output to indicate a missing bearing was detected. See figure 8A for location of

missing bearing prox switches.

The missing bearing block requires 24VDC power to operate. The prox switches

are plugged into the left two ports in no particular order. A reset signal of 24VDC

is needed to clear the missing bearing error in the block. The output from the block

is “on” or “high” when no error is detected.

Control Components Not Supplied with the Conveyor

In addition to the control components supplied with the ProSort sorter, there are

several components that must be supplied by the system control provider. Hytrol

recommends the following control components be used to protect the sorter from

damage due to product jams or other problems.

ADJUSTABLE INSTANTANEOUS MOTOR OVERLOADS

Instantaneous overloads provide protection against sorter “hang-ups” by turning

off the drive if a sudden increase in motor current is detected. By adjusting the

overload limit to slightly above the power required to operate the sorter, any

extra load on the motor, such as would be caused by a product jam or switch

malfunction, would cause the sorter to stop, possibly before significant damage is

done to the equipment.

The instantaneous overloads should be installed in the control panel for the sorter

and sized for the proper power requirements.

PHOTO-EYES

Photo-eyes are common components in systems controls. Hytrol recommends that

photo-eyes be installed at the following locations to perform listed functions. These

are, of course, in addition to other photo-eyes needed in the system.

Induction Photo-eye—A photo-eye

mounted at the infeed point of the

sorter. This eye is used to perform the

following functions:

1. Signal the system controls that a

particular package has entered the

sorter. From this point forward, the

package must be tracked using the

encoder pulses to determine when it

reaches the proper divert location.

2. Measure the length of the package

so that the system controls may assign the proper number of divert shoes to the

package for diverting. Note: Shoes are to be assigned for the entire length of the

package plus one extra shoe is to be assigned to the trailing end of the package.

3. Check for the proper gap between packages for safe sorting. It is important to

check for the proper gap here, even if it has been set prior to this point, to insure

that the packages are truly spaced properly. Attempting to sort packages with

too little gap between them can cause jams. Note: The minimum gap necessary

for sorting a package is a function of the width of the package. The charts below

should be used in checking for proper gap.

Jam/Confirmation Photo-eye—Photo-eyes mounted on each take-away spur of

the sorter, as close to the sorter as possible. These eyes perform two functions:

1. Detect a product jam at the sorter “exit point.” If a package blocks this photo-eye

for a longer time than it would take for the package to travel past the photo-eye

normally, this indicated that the package is jammed. The sorter should be stopped

and the jam cleared before restarting the sorter.

2. Divert confirmation. If a divert signal is given to a particular divert point, and no

package is detected by the associated jam/confirmation photo-eye, an error has

occurred. The sorter should be stopped and the error found and corrected before

restarting the sorter.

ProSort 421 (22° Diverts)

ProSort 421 (22° Centros de Desvio)

0”<W≤13”Minimumgap=10”

13”<W≤26”Minimumgap=16”

26”<W≤40”Minimumgap=20”

*W=PackageWidth

Note: When sorting to both sides, the

minimum gap from the above charts must

be increased by 6 in.

7