Contents

Safety Guide............................................................................................................ 1

Precautions in Operation ......................................................................................... 9

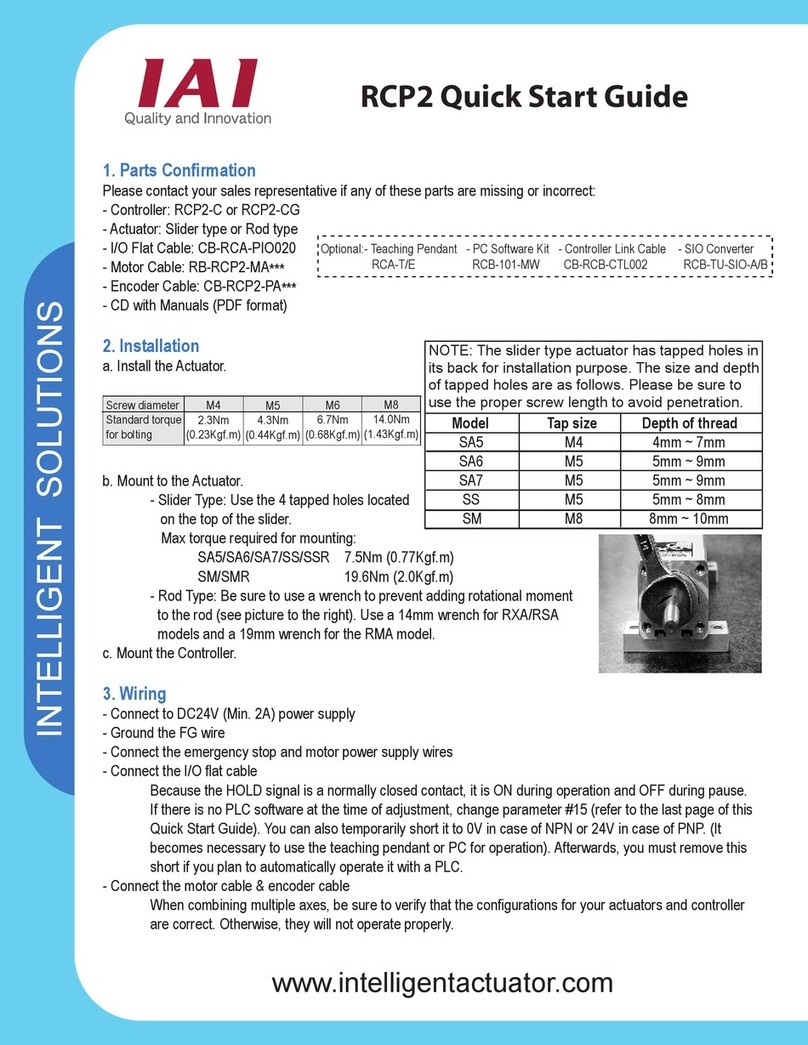

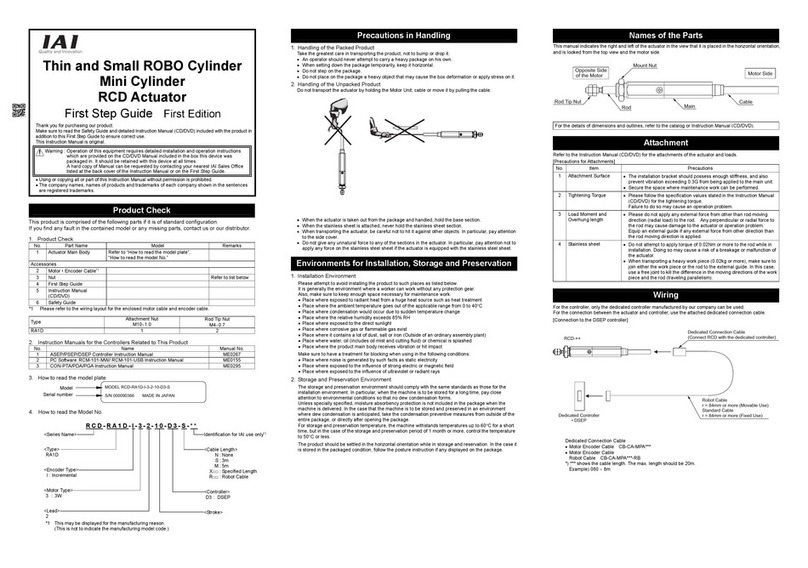

1. Product Check ................................................................................................... 15

1.1 Parts (The option is excluded.)................................................................................................... 15

1.2 Teaching Tool (Option) .......................................................................................................15

1.3 Operation manuals related to this product,

which are contained in the operation manual (CD)......................................................16

1.4 How to read the model plate ..............................................................................................16

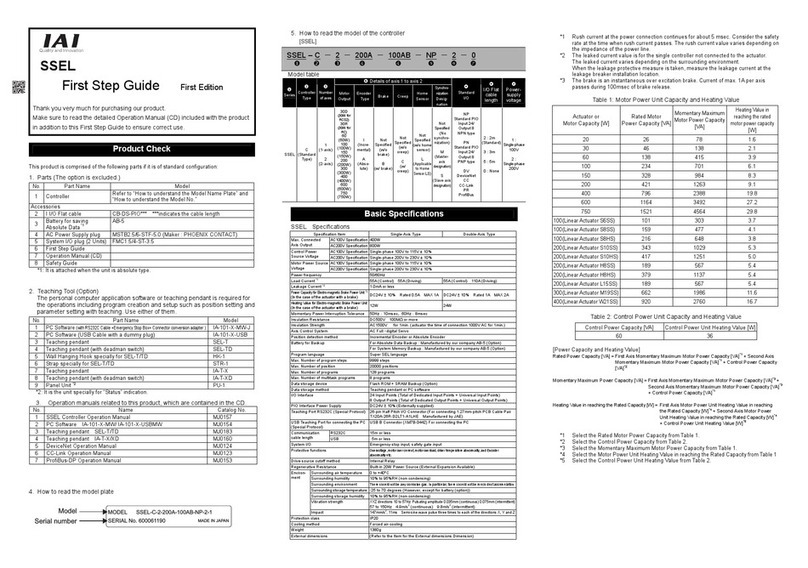

1.5 How to read the model of the controller .............................................................................16

2. Basic Specifications............................................................................................17

3. External Dimensions.......................................................................................... 19

4. Installation Environment..................................................................................... 20

5. Installation and Noise Eliminati .......................................................................... 21

5.1 Noise Elimination Grounding (Frame Ground) ...................................................................21

5.2 Precautions regarding wiring method ................................................................................21

5.3 Noise Sources and Elimination ..........................................................................................21

5.4 Heat Radiation and Installation ..........................................................................................22

6. Wiring ................................................................................................................ 23

7. LED indication.................................................................................................... 24

8. Power Connector ............................................................................................... 25

9. PIO Connector ................................................................................................... 26

10. Setting.............................................................................................................. 33

11. Timing Chart..................................................................................................... 37

12. Starting Procedures ..........................................................................................41

13. User Parame.................................................................................................... 42

14. Alarm Codes and Trouble Shooting ................................................................. 44

15. Appendix.......................................................................................................... 48

16. Warranty Period and Scope of Warranty ......................................................... 49