iDPRT SP310 User manual

User Guide

Website: www.idprt.com

Customer Service Email: [email protected]

Thermal Label & Receipt Printer

SP310

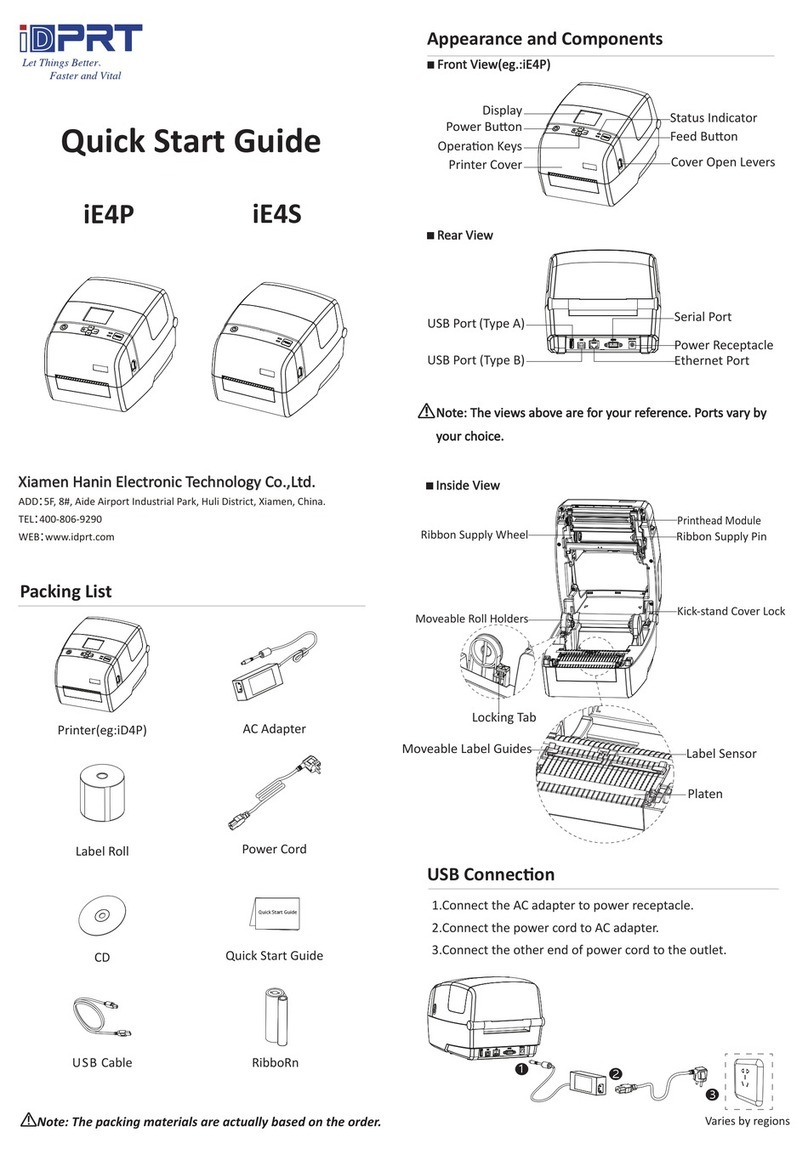

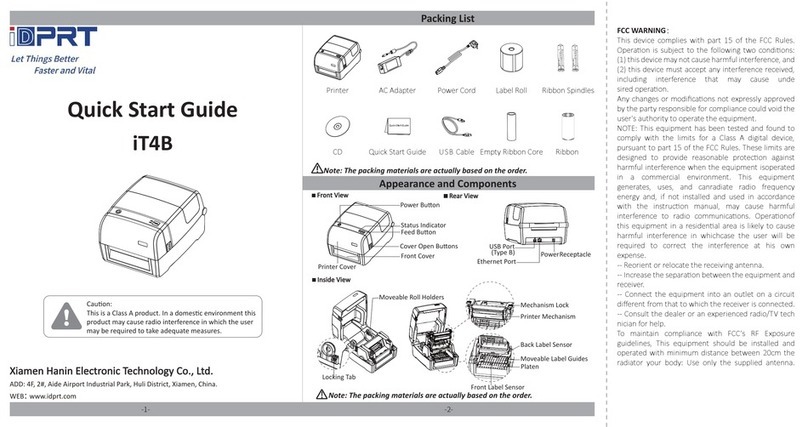

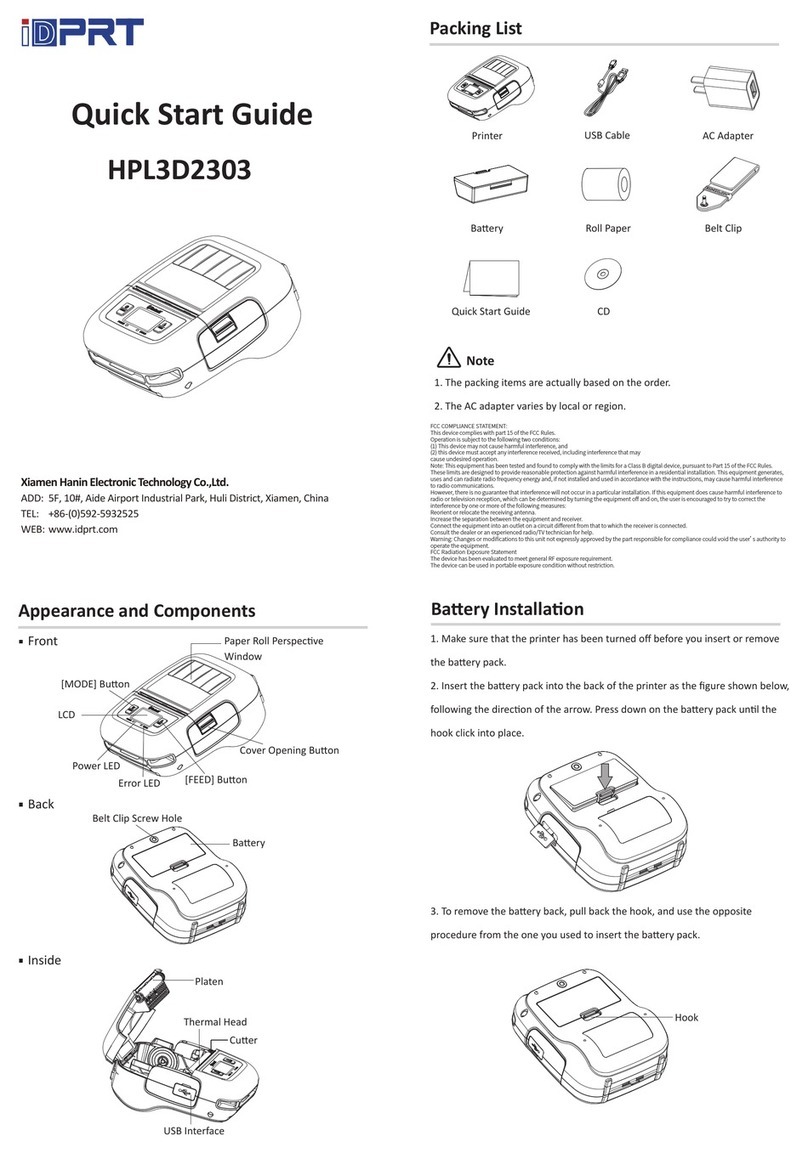

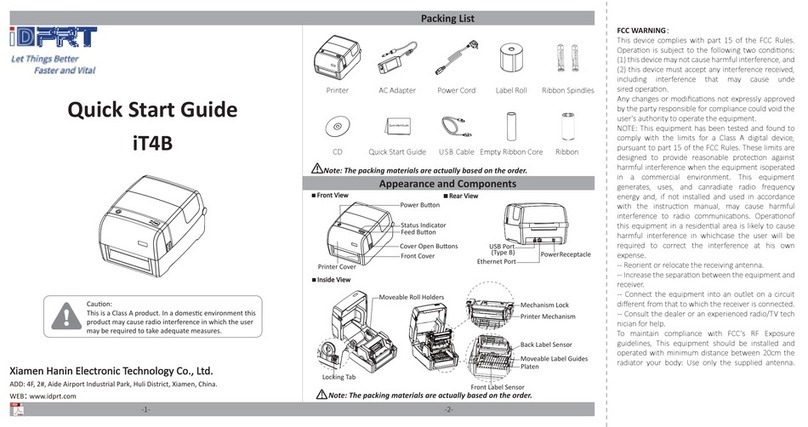

Packing List

User GuideCD

1) Unpack the printer and keep the packing items in case you need to ship

the printer in the future.

2) Any damages exist, please contact the iDPRT team.

Note: The packing items are based on the order.

-1-

Standard Accessories

Printer Power Adapter Power Cord

Cables Fastener

USB Cable Serial Cable Paper Roll

Appearance

-2-

2. Connect the AC adapter to the cable connector.

3. Connect the AC power cord to the outlet.

4. Connect the other end of the AC power cord

into the socket outlet.

5. Connect the USB cable to the printer and PC.

OFF ON

Note:

Use the original power adapter only, in case the damage caused by

charging improperly.

-3-

AC power cord

AC adapter

Cable connector

Varies by local or region

2

3

4

5

Paper Loading

Paper Loading

which is about the internal diameter of paper

Pull out the paper roll, open the paper guides to the max-width and pass the paper

-4-

of this printer contains

a sharp edge. Please

do NOT touch it.

√ ×

-5-

External Paper Roll Loading

roll entry slot

-6-

Print Self-test Page:

prints the self-test page.

-

When the printer

Driver

-7-

Warning:

1. Select one interface to connect your printer to computer.

2. Turn on the printer and check if it is connected successfully.

7.

iDPRT SP310

iDPRT SP310

iDPRT SP310

-8-

1.

Right-click the icon and choose

.

.

.

.

iDPRT SP310

-9-

3) Speed 4) Test

-10-

(

iDPRT SP310

iDPRT SP310

iDPRT SP310

-11-

Driver Removing

1.

2.

3.

4.

iDPRT SP310

iDPRT SP310

iDPRT SP310

iDPRT SP310

Warning:

as example.

1.

2.

3.

-12-

4.

5.

6.

cable).

7.

8.

-13-

iDPRT SP310

iDPRT SP310

LED Display

The printer is ready

on

on

on

on

on

Flash

Out of paper

on

Flash

-14-

The printer is ready to print with black mark label

Note:

When the temperature of the print head is higher than 80℃, a

high-temperature alarm will be issued, and when the temperature

returns to 60℃, the high-temperature alarm will be canceled and

stopped.

Print Problem

-15-

Problem Cause

1. Common

quality problem

of print.

Speed seng error. Set minimum prinng speed by the control panel,

driers and soware to aain the best prinng

quality.

ncorrect margins and

paper size.

ake sure the label size is correct before prinng.

f the content exceeds the label size, the printer

may "shrink" the size to a smaller size, causing

the fade content.

ncorrect print density

seng.

To obtain the best print quality, the print depth

should be set to the minimum set alue for your

applicaon.

The print head is dirty. Use a coon swab moistened with alcohol to

clean it from the center to the sides of the print

head. Aer cleaning the print head, do not use

the printer immediately. Use it aer the alcohol

completely eaporate aer 1 to 2 minutes) and

the print head is completely dry.

The creaon quality of

the source le is not

sasfactory.

Print a sample label to test whether the printer is

working well.

The print head is

broken.

Change another print head.

2. White spots

appear on the

label.

The print head is dirty. Use a coon swab moistened with alcohol to

clean it from the center to the sides of the print

head. Aer cleaning the print head, do not use

the printer immediately. Use it aer the alcohol

completely eaporate aer 1 to 2minutes) and

the print head is completely dry.

3. Blank label

printed.

The label is upside

downon the wrong

side.

ake sure to load the label correctly, and the

prinng side should face up.

The label is not a

"direct thermal" label.

ake sure your label is "direct thermal" label.

Printer system error. Restart the printer, connue to try to print. f

prinng is sll unsuccessful, please contact

customer serice.

-16-

Problem Cause

4. isalignment

Skip label.

The printer is

uncalibrated.

Calibrate the printer.

ethod 1: Tools--- "Automac label

learning".

ethod 2: Press and hold the feed buon

top buon) unl the blue light goes out

twice and then release

..

The tag format is incorrect. Check your label format and correct it as

needed.

5.Paper am.

The paper is notplaced

correctly in the printer. .

Open the printer coer and remoe the

ammed paper. Then clean the print head,

paper sucon port andplace the new

paper.

6. The paper is not

sucked in by the

printer.

7. The label or image

is oset during

prinng.

The paper does not

conform to the

specicaons.

Use the paper that meets the

specicaons.

Printer uncalibrated.. Calibrate the printer.

The platen is too dirty. Clean print head and platen.

The calibraon of the

paper sensor is incorrect.

Calibrate the printer.

The loading of the media

is incorrect.

nsure that the media is properly loaded.

The media is incompable.

The paper is not detected

by the paper sensor in the

middle of the printer.

When placing paper from the back entry slot,

sensor, and the paper sensor will trigger

paper is detected.

The printer uses a

Set the printer as the correct medium type.

-17-

Problem Cause

Problem Cause

8. The bar code

printed on the label

can not be scanned.

Adust the concentraon or print speed

properly.

9. Auto calibraon

failed.

The loading of the media

is incorrect.

nsure that the media is properly loaded.

The medium is not

detected by the sensor.

Calibrate the printer.

The sensor is dirty or

incorrectly posioned.

ake sure that the sensor is clean and

correctly posioned. During the calibraon

process, the gap mark or black mark

should be aligned with the paper sensor.

ncorrect media type

seng.

Set the printer media type correctly.

too light, the barcode does

There is not enough blank

space around the barcode.

the barcode on the label and other printed

areas and the edge of the label.

1. The label format

has been sent to the

printer, but it has

not been idened.

2. The DATA light did

not ash.

The communicaon

parameters are not

correct.

Check printer drier or soware

communicaon sengs.

Check the handshake protocol seng for

the printer and the sengs used must be

able to match the sengs used by the

computer host. f the drier is used, the

drier communicaon sengs related to

the connecon should be checked.

3. The label format

has been sent to the

printer, but it has

not been idened.

4. The DATA lights

ash, but not print.

The prex and the

separated character set in

the printer does not match

the character set in the

label format.

Check prex and separate characters.

The incorrect data is being

sent to the printer.

Check the communicaon sengs on the

computer to ensure that these sengs

match the sengs on the printer's printer.

f the fault sll exists, the label format

should be checked.

FCC WARNING

-

-

-

ment generates, uses, and can radiate radio frequency energy and, if not

user will be required to correct the interference at his own expense.

should be installed and operated with minimum distance between 20cm the

radiator your body: Use only the supplied antenna.

technic[email protected]

Web: www.idprt.com

-

-

-

ment generates, uses, and can radiate radio frequency energy and, if not

user will be required to correct the interference at his own expense.

should be installed and operated with minimum distance between 20cm the

radiator your body: Use only the supplied antenna.

Other manuals for SP310

1

Table of contents

Other iDPRT Printer manuals