8

Page

Safety instructions 8

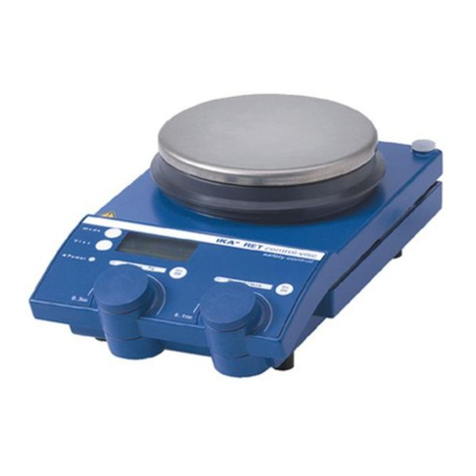

Operator’s control 9

Unpacking 9

Correct use 9

Installation 10

Maintenance 10

Accessories 10

Warranty 10

Technical data 11

EN

Contents

Safety instructions

For your protection

•Read the operating instructions in full before starting up and

follow the safety instructions.

• Keep the operating instructions in a place where they can be accessed

by everyone.

• Ensure that only trained staff work with the appliance.

• Follow the safety instructions, guidelines, occupatinal health and save-

ty and accident prevention regulations.

• Caution - Magnetism! Effects of the magnetic field have to be taken

into account (e.g. data storage media, cardiac pacemakers ...).

• Wear your personal protective equipment in accordance with the haz-

ard category of the media to be processed.

Otherwise there is a risk from:

- splashing and evaporation of liquids

- ejection of parts

- release of toxic or combustable gases.

• Use only the AC adapter supplied.

• Set up the appliance in a specious area on an even, stable, clean, non-

slip, dry and fireproof surface.

• The base plate must be clean and intact.

• Check the appliance and accessories before hand for damage each

time you use them. Do not use damaged components.

• Reduce the speed if

- the medium splashes out of the vessel because the speed is too high

- the appliance is not running smoothly

- the container moves on the base plate.

• Beware of hazards due to:

- flammable materials

- combustible media with a low boiling temperature

- incorrect container size

- overfilling of media

- unsafe condition of container.

• The appliance may heat up when in use.

• Process pathogenic materials only in closed vessels under a suitable

extractor hood. Please contact IKA if you have a questions.

• Do not operate the appliance in explosive atmospheres, with hazard-

ous substances or under water.

• Only process media that will not react dangerously to the extra energy

produced through processing. This also applies to any extra energy

produced in other ways, e.g. through light irradiation.

• Safe operation is only guaranteed with the accessories described in

the “Accessories” chapter.

• The centre of gravity of the assembly must lie within the surface on

which it is set up.

• The appliance must only be disconnected from the mains supply by

pulling out the plug-in power supply unit.

• The socket for the the plug-in power supply unit must be easely ac-

cessible.

• The appliance starts up again atomatically following a cut in the pow-

er supply.

• Abrasion of the dispersion equipment or the rotating accessories can

get into the medium you are working on.

• Whem using the PTFE-coated magnetic bars, the following has to be

noted: Chemical reactions of PTFE occur in contact with molten or dis-

solved alkaline and alkaline-earth metals, as well as with fineparticeld