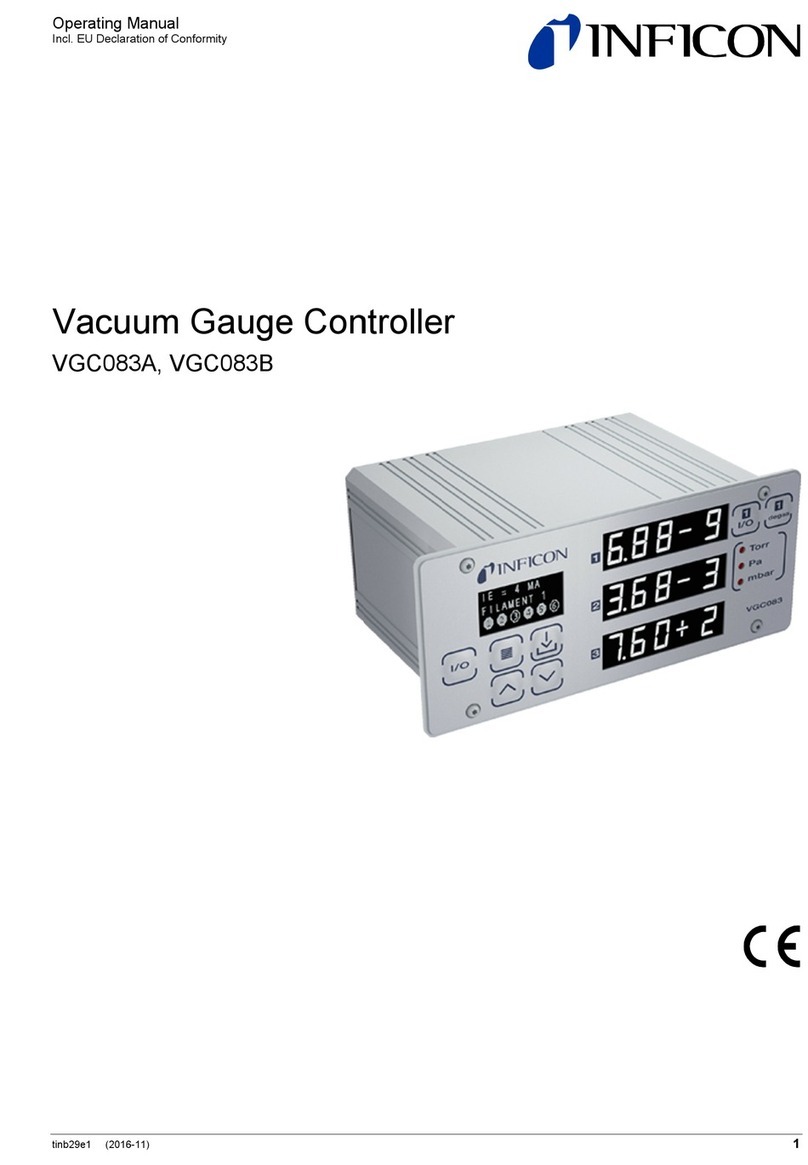

Inficon VGC031 User manual

tinb25e1-a (2019-11) 1

Vacuum Gauge Controller

VGC031

Operating Manual

Incl. EU Declaration of Conformity

2tinb25e1-a (2019-11)

Product Identification

In all communications with INFICON, please specify the infor-

mation given on the product nameplate. For convenient refer-

ence copy that information into the space provided below.

Validity

This document applies to products with part number

399-570

The part number (PN) can be taken from the product nameplate.

If your unit does not work as described in this document, please

check that it is equipped with the above firmware version

(→30).

We reserve the right to make technical changes without prior

notice.

Important User Information

There are operational characteristic differences between solid

state equipment and electromechanical equipment. Because of

these differences, and because there are a variety of uses for

solid state equipment, all persons that apply this equipment must

take every precaution and satisfy themselves that the intended

application of this equipment is safe and used in an acceptable

manner.

In no event will INFICON be responsible or liable for indirect or

consequential damages that result from the use or application of

this equipment.

tinb25e1-a (2019-11) 3

Any examples or diagrams included in this manual are provided

solely for illustrative purposes. Because of the many variables

and requirements imposed on any particular installation,

INFICON cannot assume responsibility or liability for any actual

use based on the examples and diagrams.

No patent liability is assumed by INFICON with respect to use of

information circuits, equipment, or software described in this

manual.

Throughout this manual we use notes, notices and apply inter-

nationally recognized symbols and safety messages to make

you aware of safety considerations.

Identifies information about practices or circumstances that can

cause electrical or physical hazards which, if precautions are not

taken, could result in death or serious injury, property damage,

or economic loss.

Identifies information about practices or circumstances that can

cause electrical or physical hazards which, if precautions are not

taken, could result in minor or moderate injury, property damage,

or economic loss.

CAUTION

NOTICE

tinb25e1-a (2019-11) 5

General Safety Instructions

•Adhere to the applicable regulations and take the necessary

precautions for the process media used.

Consider possible reactions with the product materials.

Consider possible reactions (e.g. explosion) of the process

media due to the heat generated by the product.

•Adhere to the applicable regulations and take the necessary

precautions for all work you are going to do and consider the

safety instructions in this document.

•Before beginning to work, find out whether any vacuum com-

ponents are contaminated. Adhere to the relevant regulations

and take the necessary precautions when handling contamin-

ated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations etc.)

on the product

•use the product with accessories not listed in the product

documentation.

6tinb25e1-a (2019-11)

Contents

Product Identification 2

Validity 2

Important User Information 2

General Safety Instructions 5

Liability and Warranty 5

1Introduction / General Information 8

1.1 Description 8

1.2 Specifications 9

1.3 Dimensions 11

1.4 Options & Accessories 12

2Important Safety Information 13

2.1 Safety Precautions - General 13

2.2 Safety Precautions - Service and Operation 14

2.3 Electrical Conditions 15

2.3.1 Proper Equipment Grounding 16

2.3.2 Electrical Interface and Control 16

2.4 Overpressure and use with hazardous gases 17

2.5 Gases other than Nitrogen / air 18

3Installation 19

3.1 Mechanical Installation - Controller 19

3.2 Electrical Installation 20

3.2.1 Grounding 20

3.2.2 Electrical Connections 20

4Setup and Operation 24

4.1 Initial Setup 24

4.2 User Interface Basics 25

4.3 Programming 26

4.4 Return to Factory Default Settings 31

5Using the Gauge with Different Gases 32

6Display 35

6.1 Display - Torr / mTorr 35

6.2 Display - mbar 39

tinb25e1-a (2019-11) 7

7Analog Output 44

7.1 Log 1-8; Log-Linear Analog Output Equation &

Table - Torr 48

7.2 Log 1-8; Log-Linear Analog Output Equation &

Table - mbar 52

7.3 Log 0-7; Log-Linear Analog Output Equation &

Table - Torr 57

7.4 Log 0-7; Log-Linear Analog Output Equation &

Table - mbar 61

7.5 NONLIN 6V; Non-Linear Analog Output Equations 66

7.6 NONLIN 6V; Non-Linear Analog Output Table - Torr 68

7.7 NONLIN 6V; Non-Linear Analog Output Table - mbar 72

7.8 NONLIN 9V; Non-Linear Analog Output Equations &

Table 76

7.9 LINEAR ANALOG OUTPUT 79

8RS485 / RS232 serial communications 81

8.1 Device Specific Serial Communication Info 81

8.2 RS485 / RS232 Command Protocol Summary 82

9Service 85

9.1 Calibration 85

9.1 Maintenance 85

9.3 Troubleshooting 86

10 Factory Service and Support 88

11 Storage 88

13 Disposal 89

EU Declaration of Conformity 90

For cross-references within this document, the symbol (→XY)

is used.

8tinb25e1-a (2019-11)

1 Introduction / General Information

1.1 Description

The VGC031 vacuum gauge controller is a convenient and inex-

pensive power supply and readout instrument for the INFICON

PGE050 Pirani Gauge Enhanced or a Granville-Phillips® 275

Convectron®. The 1/8-DIN housing can be used as a bench top,

or mounted in a cutout in an instrument panel. The VGC031 is

powered by user supplied 12 to 28 V (dc), 2 W, or by the

INFICON power supply.

Thermal conductivity gauges measure pressure indirectly by

sensing the loss of heat from a sensor to the surrounding gases.

The higher the pressure of the surrounding gas, the more heat is

conducted away from the sensor. Pirani thermal conductivity

gauges maintain a sensor (usually a wire) at some constant tem-

perature, and measure the current or power required to maintain

that temperature. A standard Pirani gauge has a useful measur-

ing range of about 10-4 Torr to 10 Torr. By taking advantage of

convection currents that are generated above 1 Torr, convection-

enhanced Pirani gauges increase the measuring range to just

above atmosphere.

The VGC031 signals and relay functions are the same as found

on similar convection gauge controllers from other manufactur-

ers. The VGC031 Controller, PGE050 vacuum gauge tube and

gauge cable can be directly interchanged with MKS Instruments

/ Granville-Phillips® (GP) 375 or 475 controller, 275 Convec-

tron® gauge and gauge cable (Remote interface, relay and pow-

er connectors are different). Various analog output scaling pro-

vide signal compatibility with GP controller series 375, 475, the

original GP 1/4 DIN 275 Analog Convectron Gauge Controller as

well as the Mini-Convectron® module.

tinb25e1-a (2019-11) 9

1.2 Specifications

Supply voltage 12 … 28 V (dc), 2 W protected

against power reversal and tran-

sient over-voltages

Connection 2-pin pluggable terminal block

(mating connector included)

Permissible temperature

Operating

0 … +50 °C

Storage

–40 … +70 °C

Relative humidity

0 to 95%, non-condensing

Use

Operating

altitude up to 2500 m (8200 ft.)

Storage

altitude up to 12500 m (41000 ft.)

Housing 1/8-DIN panel-mount enclosure

(aluminum extrusion)

Connections

Gauge

9-pin D-sub female (mating

connector provided as part of the

gauge cable)

Analog output and serial

communications interface

9-pin D-sub male

Relay outputs 6-pin pluggable terminal block

(mating connector included)

Measurement range 1.3×10

-4

… 1333 mbar

1×10-4 … 1000 Torr

1.3×10

-2

Pa … 133 kPa

Display rate

0.5 s

Units

mbar, Torr or Pa

Display

bright OLED, 4 digits

1100 Torr … 1000 Torr

4 digits

999 Torr … 10.0 mTorr

3 digits

9.9 mTorr … 1.0 mTorr

2 digits

0.9 mTorr … 0.1 mTorr

1 digit

10 tinb25e1-a (2019-11)

Interface (digital)

RS232 and 2 wire/4 wire RS485

Protocol

ASCII

Analog output

Log-linear 0 to 7 V (dc) or

1 to 8 V (dc),

1 V/decade

Linear

0 to 10 V (dc)

Non-linear S-curve

0.375 to 5.659 V (dc)

Non-linear S-curve

0 to 9 V (dc)

Switching function relays two single-pole double-throw

relays (SPDT), 1 A at 30 V (dc)

resistive, or ac non-inductive

tinb25e1-a (2019-11) 11

1.3 Dimensions

mm (inch)

Weight

≈250 g (9 oz.)

12 tinb25e1-a (2019-11)

1.4 Options & Accessories

Ordering No.

Power supply for VGC031

399-575

Input

100 … 240 V (ac), 50 … 60 Hz

Output

24 V (dc)

Cable length

2 m (6 ft)

The conventional IEC60320 AC power entry receptacle allows

use with any user supplied AC mains power cord set available

worldwide.

tinb25e1-a (2019-11) 13

2 Important Safety Information

INFICON has designed and tested this product to provide safe

and reliable service, provided it is installed and operated within

the strict safety guidelines provided in this manual. Please read

and follow all warnings and instructions.

To avoid serious injury or death, follow the safety informa-

tion in this document. Failure to comply with these safety

procedures could result in serious bodily harm, including

death, and or property damage.

Failure to comply with these warnings violates the safety stand-

ards of installation and intended use of this instrument. INFICON

disclaims all liability for the customer’s failure to comply with

these instructions.

Although every attempt has been made to consider most possi-

ble installations, INFICON cannot anticipate every contingency

that arises from various installations, operation, or maintenance

of the module. If you have any questions about the safe installa-

tion and use of this product, please contact INFICON.

This device meets FCC part 15 requirements for an unintentional

radiator, class A.

2.1 Safety Precautions - General

Hazardous voltages are present with this product during normal

operation. The product should never be operated with the covers

removed unless equivalent protection of the operator from acci-

dental contact with hazardous internal voltages is provided.

WARNING

14 tinb25e1-a (2019-11)

WARNING! There are no operator serviceable parts or

adjustments inside the product enclosure. Refer servicing to

service trained personnel.

Do not modify this product or substitute any parts without au-

thorization of qualified INFICON service trained personnel. Re-

turn the product to an INFICON qualified service and repair cen-

ter to ensure that all safety features are maintained. Do not use

this product if unauthorized modifications have been made.

WARNING! Source power must be removed from the

product prior to performing any servicing.

After servicing this product, ensure that all safety checks are

made by a qualified service person. When replacement parts are

required, ensure that the parts are specified by INFICON Sub-

stitutions of non-qualified parts may result in fire, electric shock

or other hazards. Use of unauthorized parts or modifications

made to this product will void the warranty.

To reduce the risk of fire or electric shock, do not expose this

product to rain or moisture. These products are not waterproof

and careful attention must be paid to not spill any type of liquid

onto these products. Do not use these products if they have

been damaged. Immediately contact INFICON to arrange return

of the product if it is damaged.

Due to the possibility of corrosion when used in certain environ-

mental conditions, it is possible that the product’s safety could be

compromised over time. It is important that the product be peri-

odically inspected for sound electrical connections and equip-

ment grounding. Do not use if the equipment grounding or elec-

trical insulation has been compromised.

2.2 Safety Precautions - Service and Operation

Ensure the enclosure of the VGC031 is connected directly to a

good quality earth ground.

Ensure that the vacuum port on which the PGE050 vacuum

gauge tube is mounted is electrically grounded.

tinb25e1-a (2019-11) 15

Use an appropriate power source of 12 to 28 V (dc), 2 W or use

INFICON series optional power supplies.

Turn off power to the unit before attempting to service the con-

troller.

Turn off power to the unit if a cable or plug is damaged or the

product is not operating normally according to this instruction

manual. Contact qualified INFICON service personnel for any

service or troubleshooting condition that may not be covered by

this instruction manual.

It is important that the product be periodically inspected for

sound electrical connections and equipment grounding. Do not

use if the equipment grounding or electrical insulation has been

compromised.

Do not use if the unit has been dropped or the enclosure has

been damaged. Contact INFICON for return authorization and

instructions for returning the product to INFICON for evaluation.

2.3 Electrical Conditions

WARNING! When high voltage is present in any vacuum

system, a life threatening electrical shock hazard may exist un-

less all exposed electrical conductors are maintained at earth

ground potential. This applies to all products that come in con-

tact with the gas contained in vacuum chambers. An electrical

discharge within a gaseous environment may couple dangerous

high voltage directly to any ungrounded conductor of electricity.

A person could be seriously injured or killed by coming in contact

with an exposed, ungrounded electrical conductor at high volt-

age potential. This condition applies to all products that may

come in contact with the gas inside the vacuum chamber

(vacuum / pressure containment vessel).

16 tinb25e1-a (2019-11)

2.3.1 Proper Equipment Grounding

WARNING! Hazardous voltages that could seriously in-

jure or cause death are present in many vacuum processes. Ver-

ify that the vacuum port on which the PGE050 vacuum gauge

tube is mounted is electrically grounded. Consult a qualified

Electrician if you are in doubt about your equipment grounding.

Proper grounding of your equipment is essential for safety as

well as intended operation of the equipment. The PGE050

vacuum gauge tube and enclosure of the VGC031 controller

must be connected directly to a good quality earth ground. Use a

ground lug on the PGE050 gauge vacuum connection / flange if

necessary.

WARNING! In order to protect personnel from electric

shock and bodily harm, shield all conductors which are sub-

ject to potential high voltage electrical discharges in or

around the vacuum system.

2.3.2 Electrical Interface and Control

It is the user’s responsibility to ensure that the electrical signals

from this product and any connections made to external devices,

for example, relays and solenoids, are used in a safe manner.

Always double check the system set-up before using any signals

to automate your process. Perform a hazardous operation analy-

sis of your system design and ensure safeguards and personnel

safety measures are taken to prevent injury and property dam-

age.

tinb25e1-a (2019-11) 17

2.4 Overpressure and use with hazardous gases

WARNING! Install suitable protective devices that will

limit the level of pressure inside your vacuum chamber to less

than what the vacuum chamber system components are capable

of withstanding. INFICON gauges should not be used at pres-

sures exceeding 1000 Torr absolute pressure.

In cases where an equipment failure could cause a hazardous

condition, always implement fail-safe system operation. For ex-

ample, use a pressure relief device in an automatic backfill op-

eration where a malfunction could result in high internal pres-

sures if the pressure relief device was not installed on the

chamber.

The PGE050 vacuum gauge tube connected to the VGC031

controller is not intended for use at pressures above 20 psia

(1000 Torr); DO NOT exceed 35 psig (<2½ bars) pressure inside

the sensor. If your chamber goes to higher pressures, you

should install an isolation valve or pressure relief device to pro-

tect the gauge tube from overpressure conditions. With some fit-

tings, actual safe overpressure conditions may be lower; for ex-

ample, a quick-connect, O-ring compression fitting may forcibly

release the gauge tube from the vacuum chamber fitting with

only a few psi over local uncorrected barometric (atmospheric)

pressure.

CAUTION! If the internal pressure of a vacuum gauge

device is allowed to increase above local uncorrected baro-

metric pressure (atmospheric pressure side), vacuum fit-

tings may release and possible overpressure conditions

may cause leaks that would allow the gas inside the gauge

tube to release into the atmosphere of the surrounding en-

vironment. Toxic, pyrophoric and flammable gases are ex-

amples of hazardous gases that if allowed to leak out of the

vacuum/pressure containment vessel into the atmospheric

environment, could cause bodily injury and possible dam-

age to equipment. Never expose the gauge tube internal

volume to pressure above local atmospheric pressure when

using hazardous gases.

18 tinb25e1-a (2019-11)

2.5 Gases other than Nitrogen / air

WARNING! Do not attempt to use with gases other than

nitrogen (N2) or air without referring to correction factor data ta-

bles.

INFICON gauges and modules are calibrated for direct readout

of nitrogen or air. Do not attempt to use with other gases such as

argon (Ar) or carbon dioxide (CO2) unless accurate conversion

data for N2to other gas is properly used. Refer to sections titled

"Using the gauge with different gases", "Display" and "Analog

Output" for a more complete discussion.

WARNING! Do not use the convection gauge connected

to this device in an explosive atmosphere or in the presence of

flammable gases, vapors or fumes. Do not use this device to

measure the pressure of explosive or combustible gases or gas

mixtures. The sensor wire in the gauge normally operates at

125 °C, but if malfunction should occur, the wire temperature

could exceed the ignition temperature of certain combustible

gases and gas mixture. This could cause an explosion which

could result in serious injury or death.

tinb25e1-a (2019-11) 19

3 Installation

3.1 Mechanical Installation - Controller

The VGC031 is designed for use on a bench top, or it may be

mounted in an instrument control panel.

To mount the VGC031 in a panel:

1. Make a cutout in your instrument control panel as shown in

the drawing above. Be sure to allow clearance behind the

panel for the instrument as well as connectors and cables at

the rear of the instrument

2. Gently pry the front panel bezel loose and remove.

Bezel

Screw mounting

brackets on either

side

20 tinb25e1-a (2019-11)

3. Slide the VGC031 into the panel hole cutout.

4. On either side of the VGC031 are two screw-mounting brack-

ets. When the screws in the front of the instrument are turned

counterclockwise, the hold-down brackets recess out of the

way into the VGC031 housing. When these screws are turned

clockwise, the brackets rotate out 90° behind the panel.

Tighten these screws until the brackets hold the VGC031 in

place against the panel.

5. Press the front panel bezel back in place.

3.2 Electrical Installation

3.2.1 Grounding

Be sure the vacuum gauge and your vacuum system are

properly grounded to protect personnel from shock and injury.

Be aware that some vacuum fittings, especially those with O-

rings, may not produce a good electrical connection between the

gauge and the chamber it is connected to.

3.2.2 Electrical Connections

A good recommended practice is to remove power from any

cable prior to connecting or disconnecting it.

The INFICON VGC031 may replace similar controllers from

other manufacturers, such as the Granville-Phillips®375 control-

ler. Many of these other controllers employ the same 9-pin and

15-pin D connectors, but they do not all use the same signal /

pinout configurations. If you wish to use your existing cables, be

sure to check compatibility with the tables on the next page.

Rewire your cables as necessary.

Other manuals for VGC031

1

Table of contents

Other Inficon Controllers manuals

Inficon

Inficon TPG300 User manual

Inficon

Inficon XTC/3 User manual

Inficon

Inficon TPG300 User manual

Inficon

Inficon VGC083C User manual

Inficon

Inficon VGC083B User manual

Inficon

Inficon MAG050 User manual

Inficon

Inficon VGC083A User manual

Inficon

Inficon Protec P3000 Operational manual

Inficon

Inficon IC6 User manual

Inficon

Inficon SQC-310 User manual