2

components. Do not use the product in high humid or dusty environments.

•Using an incompatible battery may cause explosion. When battery replacement is

required, please consult the manufacturer first, and choose batteries of the same or

equivalent type suggested by them. Do not disassemble, crush, puncture the

batteries or short circuit the external connection point, and do not expose them in

the environment over 60°C (140°F). Never throw batteries into fire or water. Please

do not attempt to open or repair the batteries. Dispose of used batteries properly.

Do not put waste batteries, circuit boards or other components that may contain

batteries with other wastes. For battery recycling, please contact the local recycling

center.

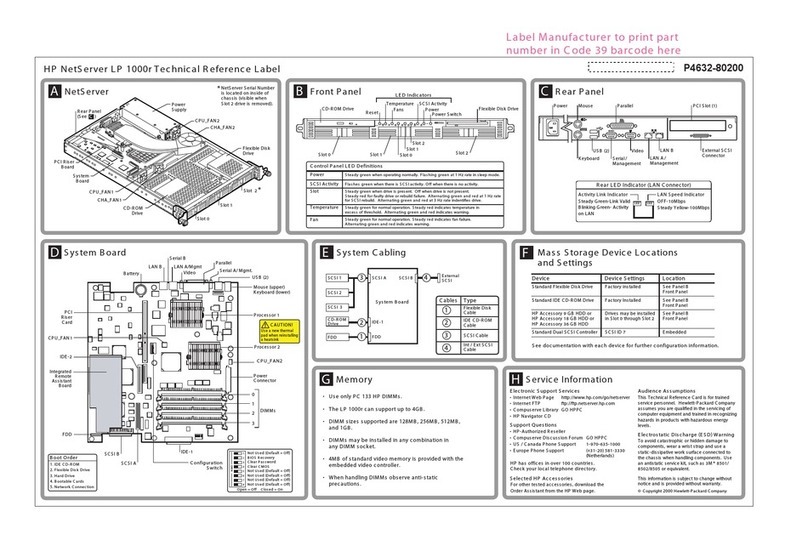

•For independent cabinets, please install front and side stabilizers before installing

the equipment into the cabinet. For cabinets connected with other cabinets, please

install front stabilizers first. Failure to install the corresponding stabilizers before

installing the equipment into the cabinet may cause the cabinet to tip over, possibly

leading to personal injury. Hence, please do make sure to install stabilizers before

installing the equipment into the cabinet. After installing the equipment and other

components into the cabinet, only one component can be pulled out from the

cabinet through its sliding part at one time. Pulling out several components at the

same time may cause the cabinet to turn over, resulting in serious personal injury.

•Please do not move the cabinet on your own. Considering the height and weight of

the cabinet, the moving of the cabinet should be completed by at least two people.

Moving it without adequate, trained personnel could result in severe injury or

death.

•It is prohibited to directly short-circuit the copper busbar. Please do not touch the

copper busbar when the cabinet is powered on.

•This is a Class A product, and may cause radio interference. In such case, users may

need to take necessary measures to mitigate the interference.

1.2 Precautions

The following considerations may help avoid problems that could damage the

components or cause data loss, etc.

•In the event of the following, please unplug the power plug from the outlet and

contact Inspur Customer Service:

-The power cables, extension cables or power plugs are damaged.

-The products get wet.

-The products have fallen or have been damaged.

-Other objects have fallen into the products.

-The products do not or cannot function normally even when you operate