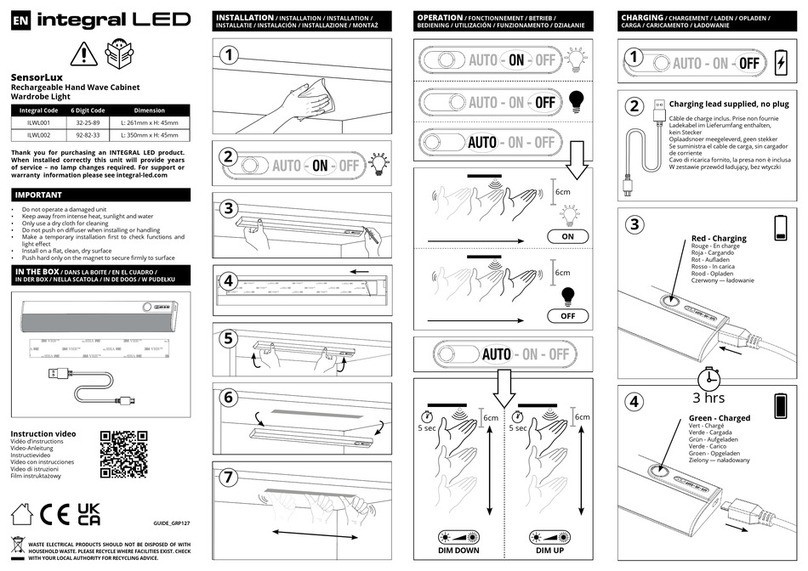

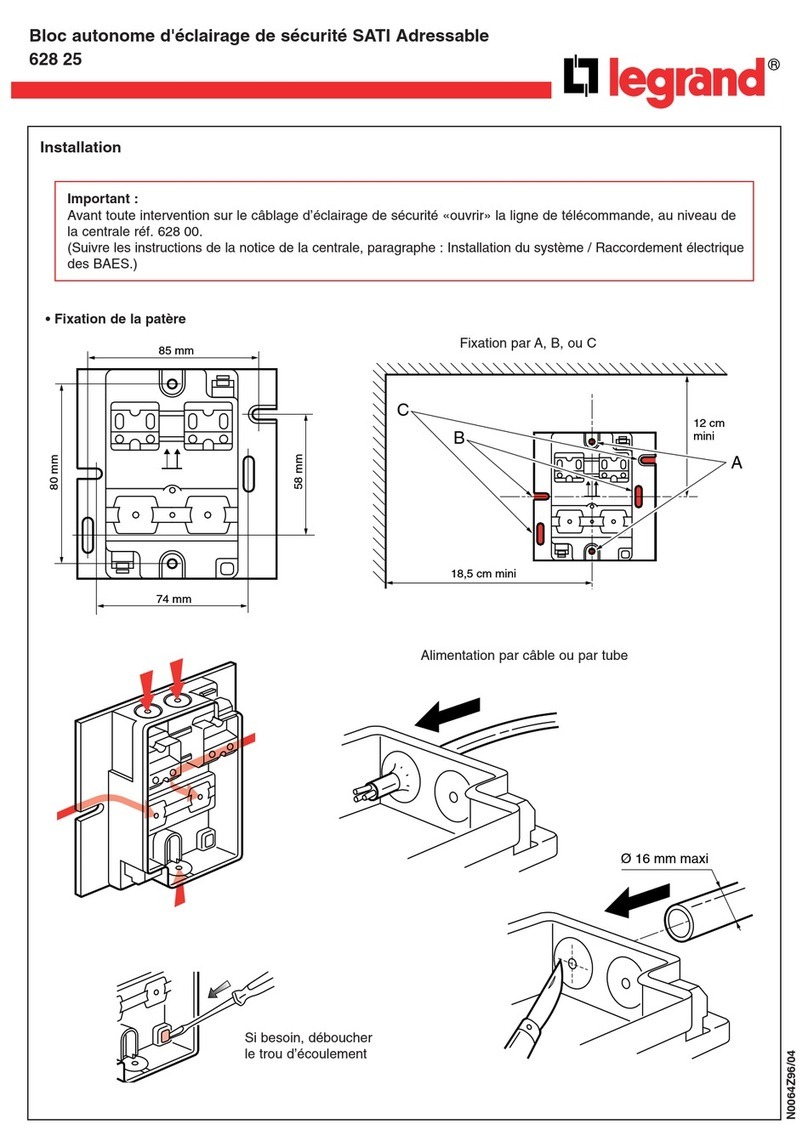

Fig.2

>=80mm

Fig.4

Fig.5

Fig.6

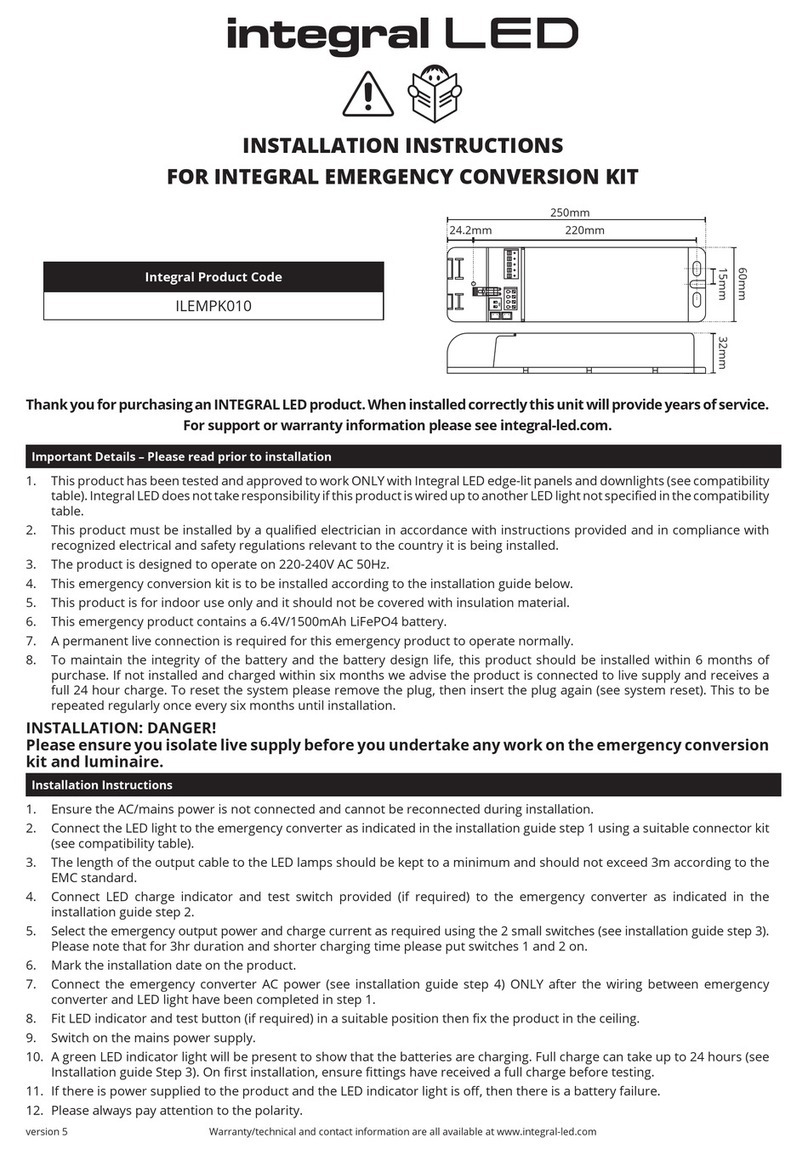

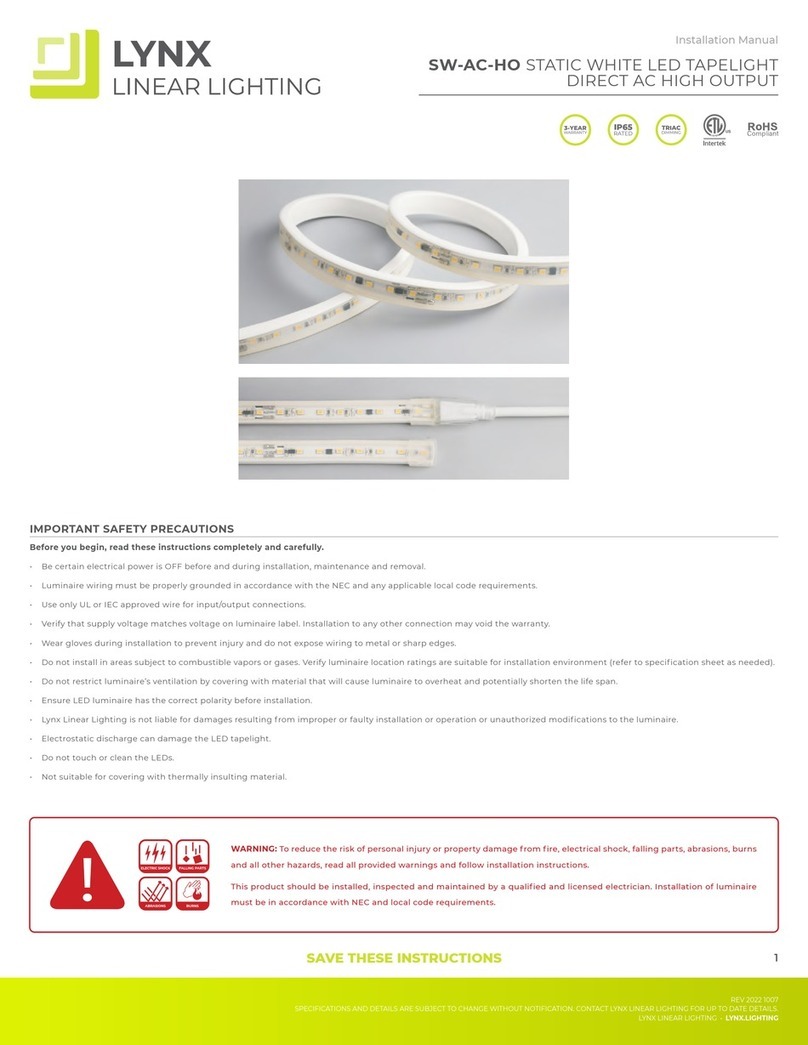

A) PRE-INSTALLATION GUIDE

Take some time to plan your project. The specication, length, mounting position and

distance from an object determines the appearance of a lit LED strip. Consider the

placement of the LED driver and wires and how the LED strip will be turned ON and

OFF. Calculate the total wattage required.

We recommend that you test the strip position before tting by temporarily holding

the LED strip in place using a suitable masking tape if required. Safely connect the

power supply (see instructions). You can then carefully move the strip to try dierent

angles and positions to gain the desired illumination eect. Check for reections and

shadows.

Consider the surface you are applying the LED strip to; the surface should be stable,

clean and smooth. On removal of a xed LED strip - damage to the substrates may

occur. Take care in measuring the length required before cutting the strip, take into

account the space needed for the connection wires.

• Do NOT press or twist the strip or other components during installation (Fig.1).

• Do NOT power the strip in the reel.

• The LED strip must only be installed in sheltered areas (indoor or outdoor). The unit

is protected against water jets and dust. Not suitable for water immersion.

• The Integral LED strip has excellent exibility but requires the bending diameter to

be no smaller than 80 mm (Fig.2).

• The strip is pre-tted with positive and negative connection wires at both ends.

• Check the supply voltage and wire connections before switching the power ON.

B) INSTALLATION INSTRUCTIONS

1) To ensure a successful installation, please read the complete guide

2) Release the LED strip from the package and unreel.

3) Measure and cut the LED strip to the required length (only cut at the cut marks with

the power OFF). Please see the instructions below to seal the strip -section C.

4) For a secure x, supplied screws or alternative xings may have to be used based on

the mounting substrate.

5) Metal mounting clips can be applied to secure the strip at approximately 50 cm

intervals. Carefully position and x the clips, insert one side of the strip into the clip,

and gently push the other side to secure. You can also use the optional plastic clips

if you prefer (supplied without screws). The supplied screws are designed for use

with the metal clips.

6) Once the strip is axed, it is then ready to be wired. Please see section D.

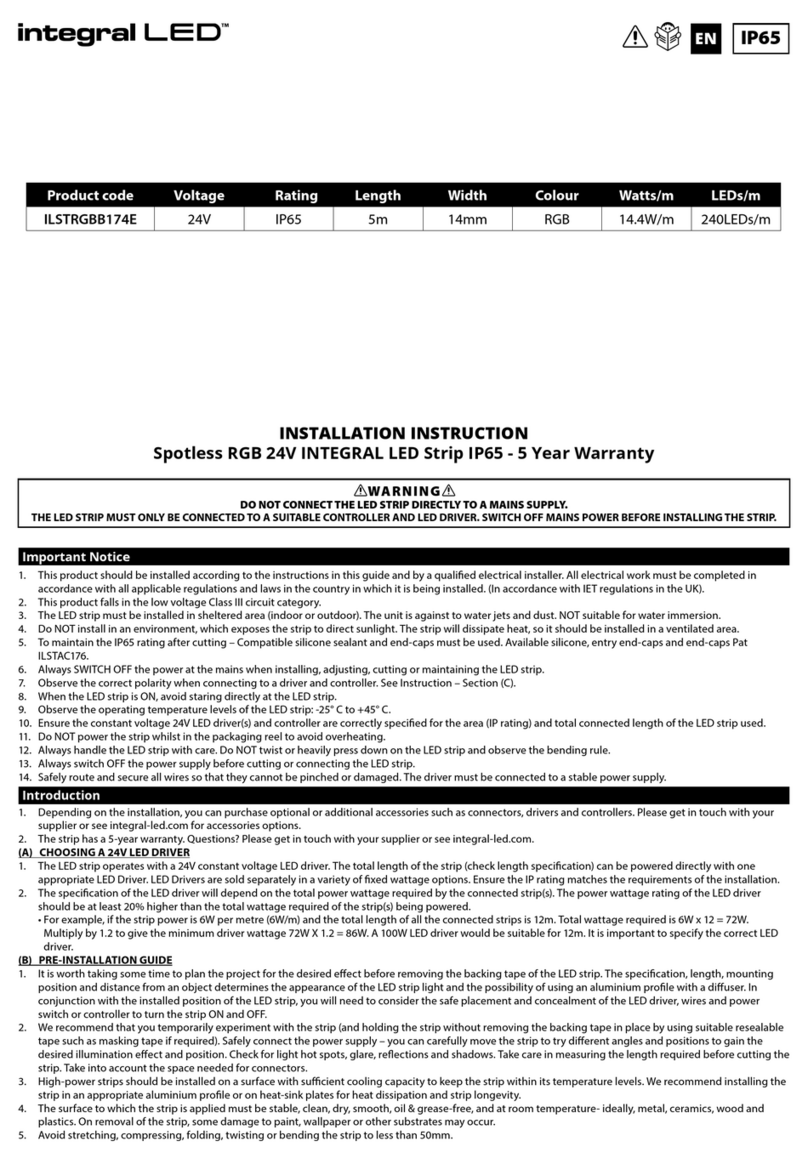

C) CUTTING THE IP65 STRIP - Switch OFF the power.

If the strip needs to be cut to length, please measure carefully and cut squarely at the

appropriate cut marks only using a sharp cutting implement (Fig.3).

The silicone is required to maintain the IP65 rating. Wear protective gloves and

eyewear and work on a protected surface (in case of spills) in a well-ventilated area.

We recommend that the strip is allowed to dry for 24hrs and to cure for 7 days before

subjecting the strip to water. For control, always apply from the nozzle (cut the nozzle

4-5mm from the top).

1) If the strip needs to be cut to length or into two or more lengths, all non-

powered ends must be sealed using a silicone sealant and a sealed end cap.

a. Cut the strip squarely with a sharp cutting implement - only at the black cut marks

on the rear of the strip. – ll the top of the sealed end cap with silicone using the

nozzle. Then carefully ll the end of the strip. You can use your gloved nger or a tool

to make sure all gaps are lled and a good seal made. Seal the end cap over the strip.

Wipe any excess silicon. (Fig.4)

2) All powered ends have to be sealed using a silicone sealant and a wired sealed

end cap

a. Cut the strip squarely with a sharp cutting implement - only at the black cut marks.

For an end to be powered, carefully remove just enough of the diuser on the strip

above the contacts to solder on wires. Clean the contacts with emery paper and

then solder on the power wires – Please pay attention to the polarity.

b. Once the wires have been soldered, carefully and safely apply power to the strip to

Fig.3

Fig.1