9

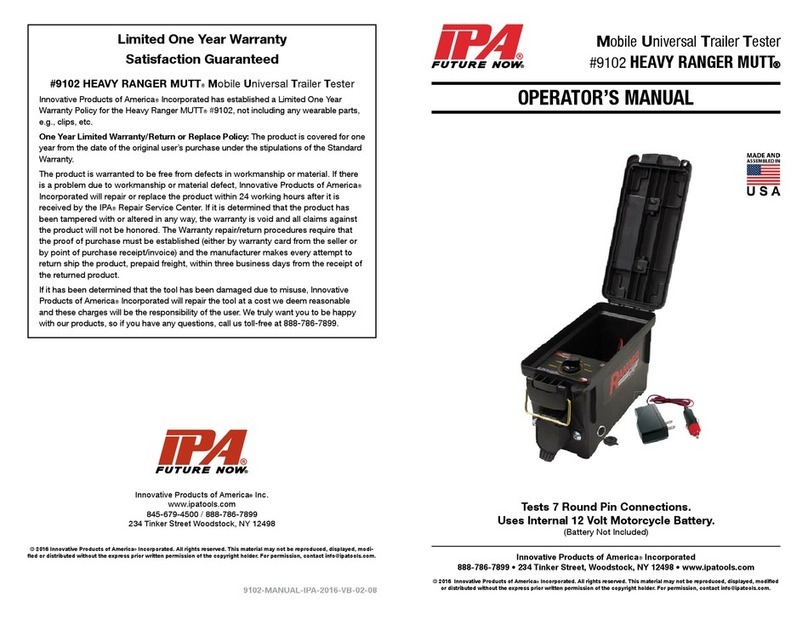

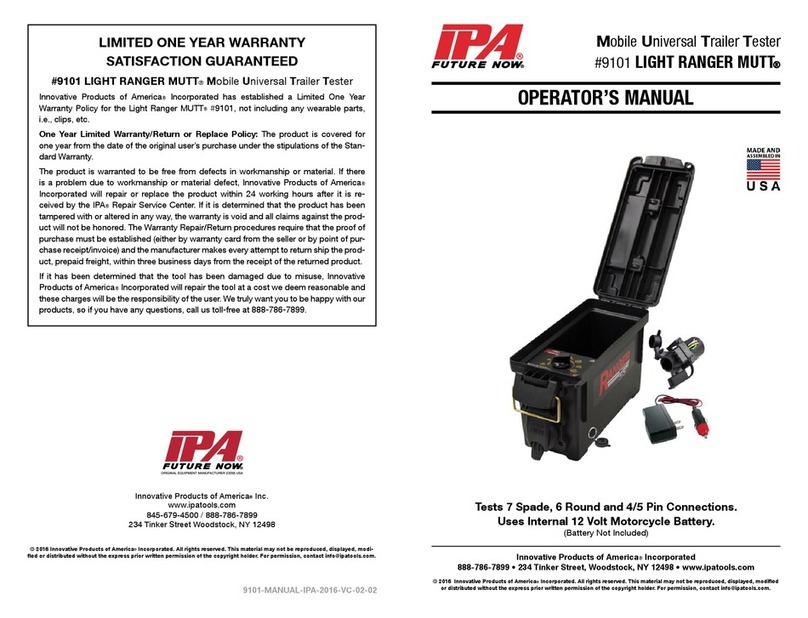

3.2 ELECTRICAL CONTROL PANEL

A. POWER SOURCE SWITCH

Select between Internal Battery, External Power or Power Off.

Center: OFF (battery charge in this position only)

Up: Installed Battery ON

Down: External Power ON (power supply is an optional accessory)

B. BACKLIT 30 AMP AMMETER

Meter shows current draw of a selected circuit up to 30 amps.

C. TROUBLE WARNING INDICATORS

Flashing red LEDs indicate problems that may exist in a selected circuit. This includes

the Overload Indicator, Open Circuit Indicator, and Reversed (Battery) Polarity Indicator.

D. MUTE SWITCH

ON disables sound. OFF enables sound.

E. AUTO CYCLE INDICATOR

Illuminates when Auto Cycle Mode is engaged.

F. VOLTAGE INDICATOR

Shows supplied battery voltage integrity. Operating voltage range: 12/24 volt DC.

G. GROUND INTEGRITY

A large green LED above the control knob indicates ground status. Ground

integrity is automatically veried when power is turned on.

H. CONTROL KNOB

Knob activates all electrical test modes and circuits to be diagnosed.

I. CIRCUIT INDICATORS

The small green LEDs illuminate or blink in testing phase.

J. TRAILER TYPE SWITCH

Selecting a mode changes wiring conguration: NATO/7 Spade/6/5/4 Pin,

7-Way Round Pin.

K. 30 AMP FUSE SOCKET

Overload protection.

A

B

D

Electrical Control Panel

PROGRAM REMOTE:

Hold down largebutton on remote while

powering up unit. Releaseafter 5 seconds.

AUTO CYCLE:

Press and releasecontrol knob.

ALL CIRCUITS ON:

Press and hold control knob or remote

for 5 seconds.

*

ACCESS ABS BLINK CODES:

Refer to ABS Manufacturer Manual todetermine

mfg. sequence. Select ABS or BRAKE LIGHT. To

flash power between circuits, press and release

control knob.To maintain power between circuits,

hold control knob for3seconds until beep.

M

OBILE

U

NIVERSAL

T

RAILER

T

ESTER

PULL KNOBTO ADJUST

MAX.120 PSI

AIR BRAKECONTROLS

WARNING: CHOCK ALL TRAILER WHEELS

BEFORE APPLYING AIR PRESSURE

OPENCLOSED OPENEXHAUST/

REMOTE

CLOSED

ON

OFF

VISIBLE ALERTS

Ground Integrity: During startup, all

circuits blinking indicate poor ground

pin or chassis ground problem.

Individual circuit(s) blinking indicates

bad return ground for that circuit.

(Check cable/pin connection.)

Open Circuit: Blinking circuit with

audible alert indicates disconnected

or open circuit.

Crossed Circuit: Selected circuit is

illuminated and crossed circuit(s)

blinks with audible alert.

INLET AIR PRESSURE IS DISPLAYED ON

EMERGENCY SIDE GAUGE: To set pressure,

connect shop air, push switch to open,

then adjust regulator knob.

LEAK DOWN TEST (Emergency/Service): To charge system

with air, set switch to open and fill to desired pressure.

Close switch to shut off air flow and note any pressure

drop through needle movement.

BRAKE ACTUATION: Open emergency side switch to release

parking brake. Open service side switch to actuate service

brakes. To operate service brakes with remote, set switch

to exhaust/remote and press small button on remote control.

30 30

1515 0

BRAKE

B/O STOP

ELEC. BRAKE

ABS

REVERSE

NATO/7 SPADE/6/5/4 PIN MODE

7-WAY ROUND PIN MODE

BRAKE

LIGHTS

GROUND

INTEGRITY

TAIL/TAG

B/O RUNNING

AUXILIARY

RIGHT TURN

RIGHT TURN

LEFT TURN

LEFT TURN

CLEARANCE

TAIL LIGHTS

*

ABS

TRAILER TYPE

OFF ON 7-WAY

ROUND PIN

NATO

7 SPADE

6/5/4 PIN

C

F

E

G

H

I

J

K