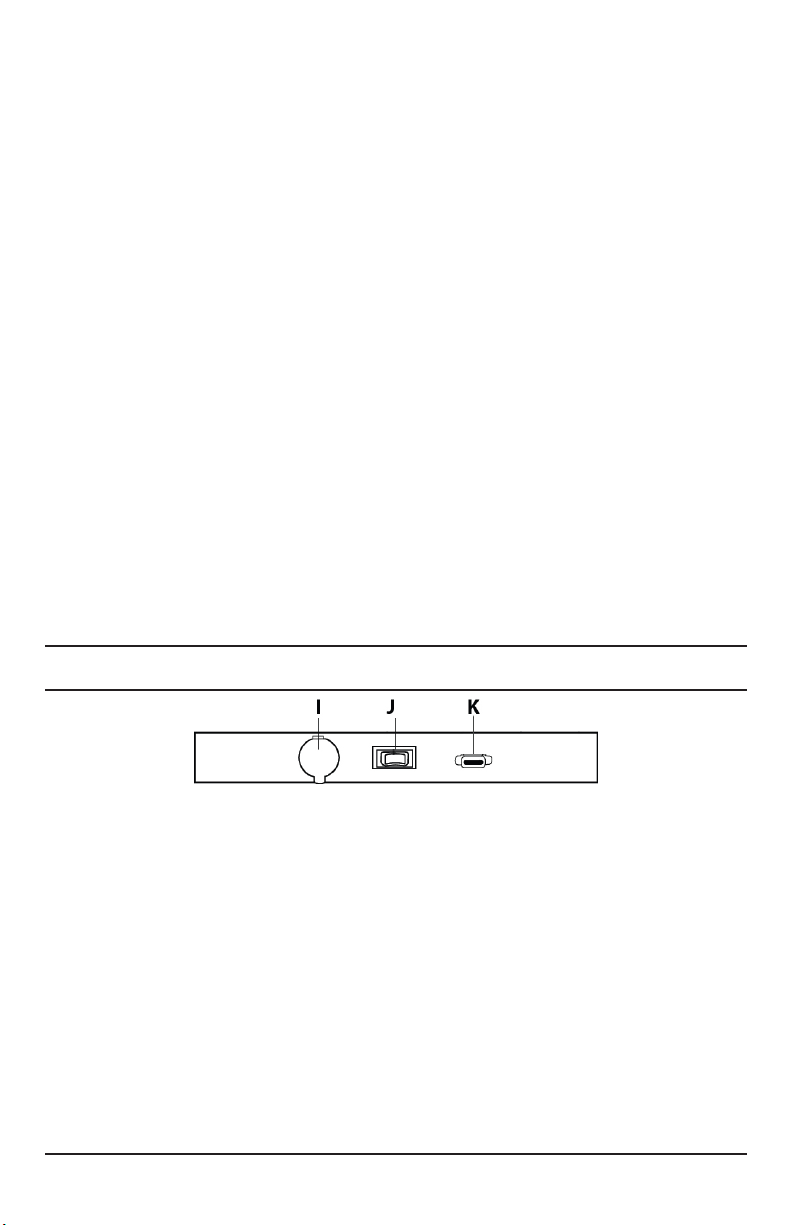

10

OPERATING INSTRUCTIONS

This section contains information on the usage of the #9004A Mobile Universal Trailer

Tester (SMART MUTT®).

7 WAY FLAT/SPADE PIN TESTING PROCEDURE

To avoid false readings:

• Visually inspect trailer socket for corroded and/or squeezed pins.

• Bad or broken socket pins can cause false readings. Clean all connections and load

socket with a dielectric grease.

MANUAL TESTING MODE

NOTE: Prior to any testing on the MUTT®, connect the trailer to the tester or you will

receive erroneous readings. The MUTT®is to be used while connected ONLY.

• Secure the 7 at/spade cable from trailer to socket on the right side of the tester.

Initial power starts a test cycle through all the LEDs. This performs the Ground

Integrity test / Open Circuit test.

• Check Voltage Indicator (Fig. 2-B) for green illumination. In the case of low or weak

supply voltage, yellow color illuminates. Red illumination from the Voltage Indicator

shows inadequate power supply. Also see Warning Indicator section (page 12).

• Ground Integrity Check: When the SMART MUTT® is rst turned on, notice the green

lights circling the dial. This indicates the SMART MUTT® testing for ground integrity.

If there is a lack of ground, all the green lights begin to ash to alert you to the ground

problem. If you only see one green light ashing, this indicates an open circuit (check

TRAILER CONFIGURATION SET-UP

The 9004A Smart MUTT is a microprocessor controlled diagnostic trailer tester speci-

cally designed for testing lights and electric brakes on trailers with 4, 5, 6 Round pin and

7 Spade Pin type connections. Every time you power up the tester, the internal com-

puter wants to know which type of trailer connection you are testing. Note, this phases

is known as Trailer Conguration Set up and is indicated by a high speed ickering of

the LEDs surrounding the control knob. If left untouched after 15 seconds, the tester will

always default to a 7-spade pin conguration. However, if the user is testing a 4, 5, or

6 round Pin type trailer connection, this setting can be adjusted by rotating the control

knob counterclockwise to select the desired number of circuits (as noted on the face

panel). Trailer Conguration Setup is repeated each time the unit is powered up.

Testing 4, 5, and 6 Round Pin Type Trailer Connections

The 9004A is hard wired to a 7-spade pin connector, located on the side of the tester.

Each unit is supplied with a plug-in adapter, which will adapt the 9004A to 4,5 and 6

round pin type connections. To test trailers with these types of connections, this adapter

must be plugged In line between the Tester and the Trailer. The instructions above for

Trailer conguration set up, should be used for more efcient and accurate testing.

Call 888-786-7899 with any technical questions.