8

SHORT CIRCUIT AND OVERLOAD TESTING

Short Circuit: When a positive power source (12V +) is directly connected to or touching

the ground (-), wire insulation can wear through due to vibration; exposed copper wire can

make contact with the metal trailer frame resulting in a short circuit and a blown fuse in

the vehicle.

Overload: When the load (lights and/or electric brakes) attempts to draw more current

(amps) than the circuit was designed to handle, this often results in blown fuses.

Summary: The Ranger MUTT® is capable of providing up to 10A of current to a selected

circuit. It is equipped with an internal, auto-resetting thermal circuit breaker, which is

designed to remove power to the selected circuit when the load exceeds 10A in overload

condition. Once power is removed, the circuit breaker requires a 30-second cooldown

cycle until power can be reapplied. If the source of the excessive current draw, i.e., the

overload condition is still present, the circuit breaker will immediately remove power once

again. This process will be repeated until the source of the excessive current draw is

removed. Most small trailers should not exceed 10A per circuit when wired properly. You

should check the specied current draw for each light bulb or LED on the trailer circuit to

determine whether it’s an overload condition, short circuit condition or faulty equipment,

e.g., electric brakes, lights, harnesses, etc.

NOTE: The auto-resetting thermal circuit breaker used in the Ranger MUTT®is thermally

activated and requires a short cooldown time between uses. The more often it is tripped,

the longer the required cooldown time before it will become active again.

TEST 6-WAY ROUND AND 4/5-PIN TRAILERS WITH

3-WAY ADAPTER

TESTING PROCEDURE

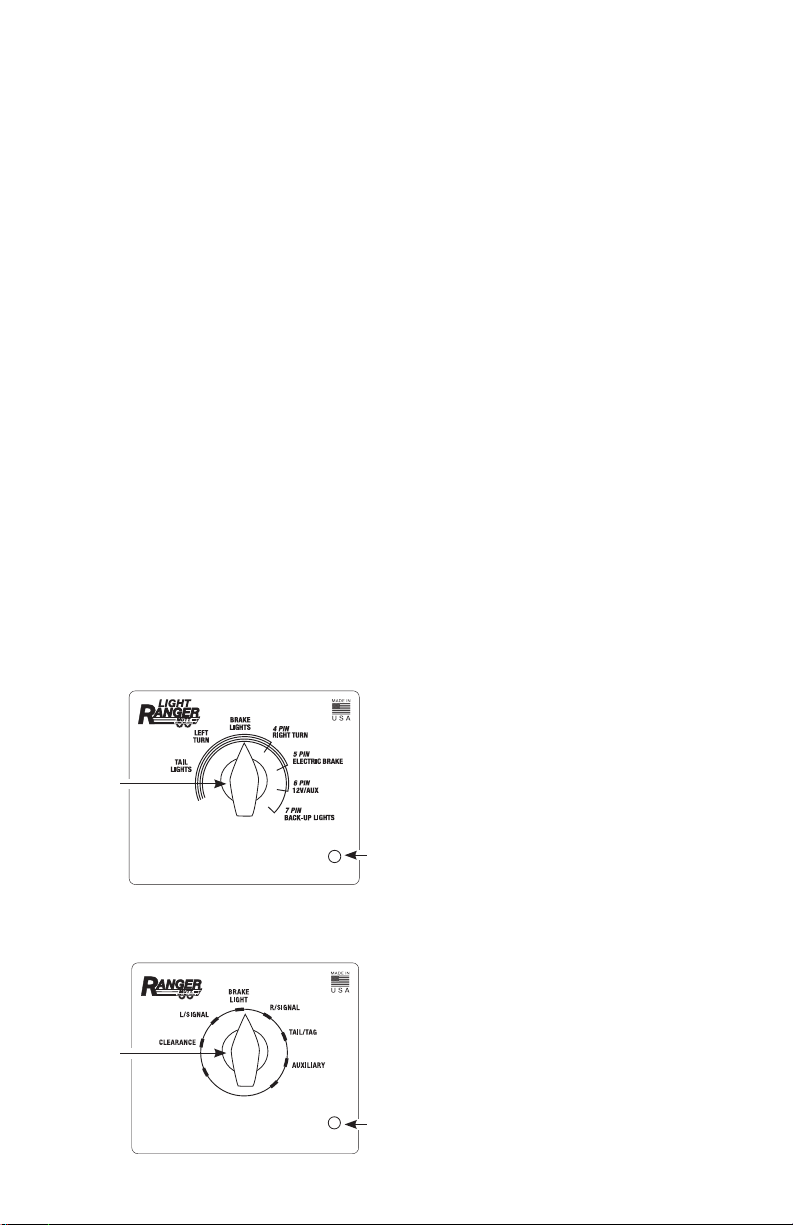

The #9101 Light Ranger MUTT® is designed to test trailers with 6-way round and 4/5-pin

connectors with the use of the 3-way adapter. The faceplate on the Ranger MUTT®shows

which functions are supplied for each pin layout. For example: a 5-pin trailer is wired for

tail lights, left turn, brake lights, right turn and electric brakes, but not 12V aux. or backup

lights. Consequently, when those circuits are selected on the Ranger MUTT®, they do not

power anything on a 5-pin trailer. See g. 2 for the #9101 faceplate layout. The supplied

adapter provides an easy way to plug 4, 5 or 6-pin trailers into the Light Ranger

MUTT . A brief explanation of how to get started is provided below.

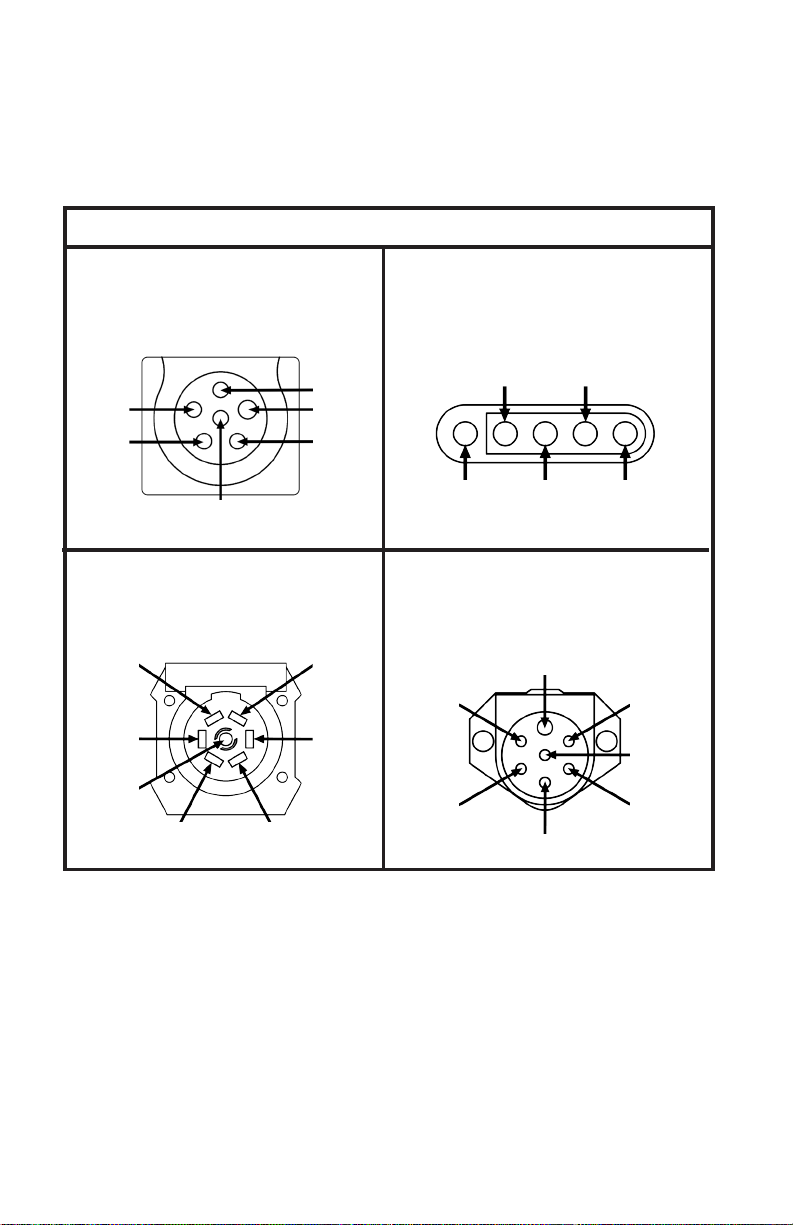

1. Plug the 3-way adapter into the 7-way socket on the Ranger MUTT®.

2. Be sure to push rmly until the key is down far enough for the ap to lock in behind it.

3. Plug the trailer into the proper terminal on the 3-way adapter. NOTE: The 5-pin

connector also works for 4-pin trailer sockets.

4. To begin testing the trailer, turn the control knob to the desired circuit

(as indicated on the faceplate).

5. Once the knob is turned to the selected circuit, power is being sent to the

corresponding wire on the trailer.

6. Follow the 7-way pin testing procedure (pg. 7) section for further information.