ENGLISH

2

1. INDEX

1.

INDEX................................................................................................................................... 2

2.

GENERAL INFORMATION.................................................................................................. 3

2.1.

S

COPE OF THE MANUAL

...................................................................................................................3

2.2.

I

DENTIFYING THE MACHINE

.............................................................................................................4

2.3.

D

OCUMENTATION PROVIDED WITH THE MACHINE

...........................................................................4

3.

TECHNICAL INFORMATION............................................................................................... 4

3.1.

G

ENERAL DESCRIPTION

...................................................................................................................4

3.2.

L

EGEND

..........................................................................................................................................4

3.3.

D

ANGER ZONES

...............................................................................................................................4

4.

SAFETY INFORMATION ..................................................................................................... 5

4.1.

S

AFETY REGULATIONS

....................................................................................................................5

5.

HANDLING AND INSTALLATION....................................................................................... 8

5.1.

L

IFTING AND TRANSPORTING THE PACKAGED MACHINE

..................................................................8

5.2.

C

HECKS ON DELIVERY

.....................................................................................................................8

5.3.

U

NPACKING

–

A

SSEMBLY

...............................................................................................................8

5.4.

B

ATTERIES

......................................................................................................................................9

5.4.1.

Batteries: preparation ................................................................................................................9

5.4.2.

Batteries: installation and connection........................................................................................9

5.5.

T

HE BATTERY CHARGER

...............................................................................................................10

5.5.1.

Choosing the battery charger...................................................................................................10

5.5.2.

Preparing the battery charger...................................................................................................10

5.5.3.

ON BOARD battery charger ...................................................................................................10

5.6.

L

IFTING AND TRANSPORTING THE MACHINE

..................................................................................11

6.

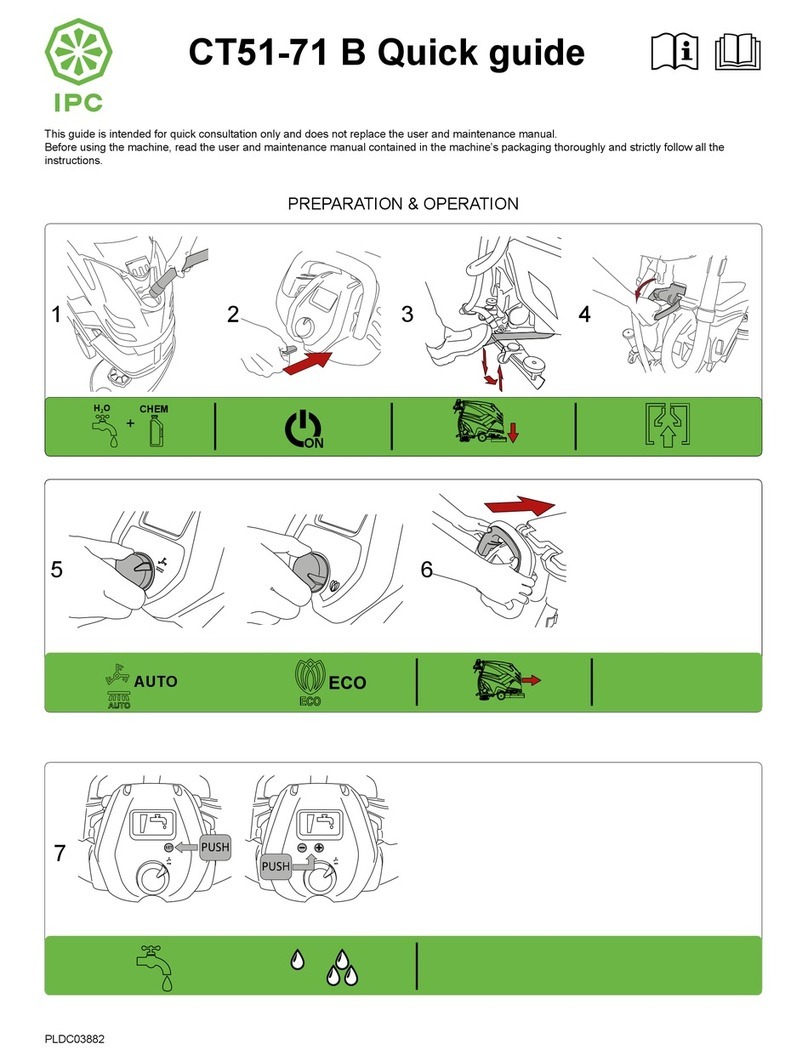

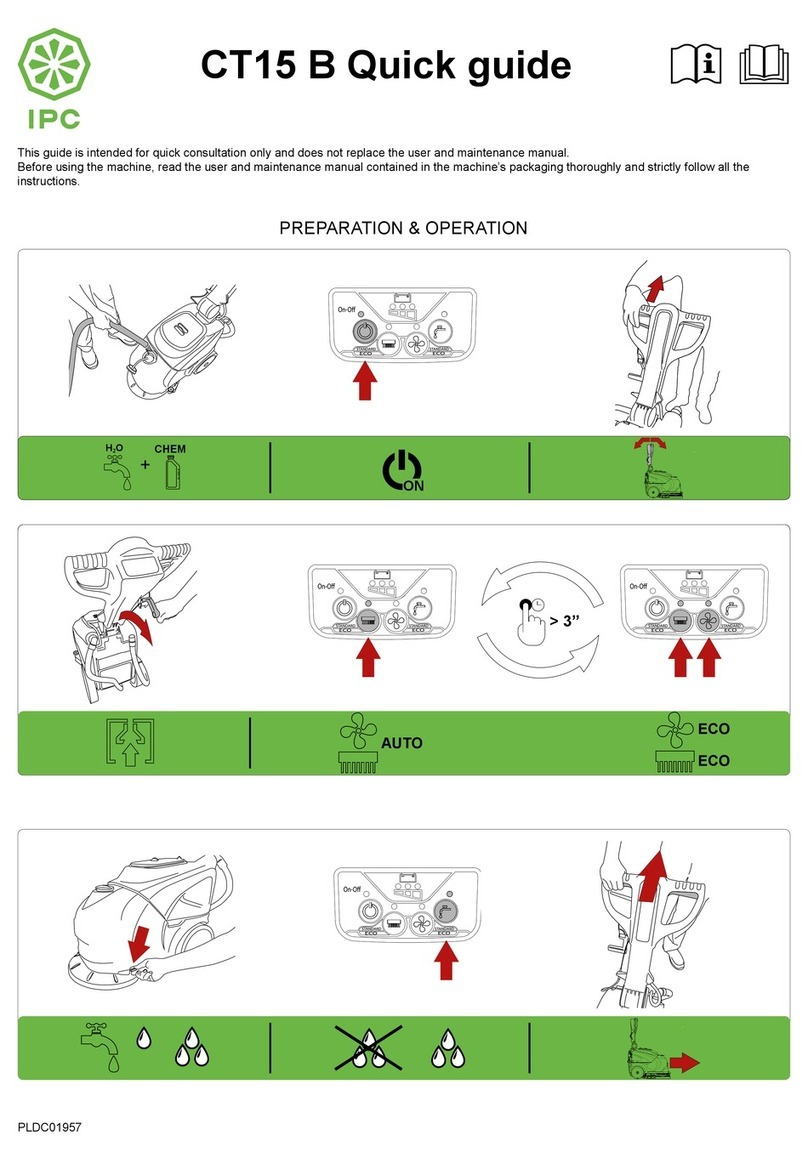

PRACTICAL GUIDE FOR THE OPERATOR..................................................................... 11

6.1.

C

ONTROLS

-

D

ESCRIPTION

............................................................................................................11

6.2.

M

OUNTING AND ADJUSTING THE SQUEEGEE

..................................................................................11

6.3.

M

OUNTING AND CHANGING THE BRUSH

/

ABRASIVE DISKS

..............................................................12

6.4.

D

ETERGENTS

-

I

NSTRUCTIONS

.......................................................................................................12

6.5.

P

REPARING THE MACHINE FOR WORK

............................................................................................12

6.6.

W

ORKING

......................................................................................................................................13

7.

PERIODS OF INACTIVITY................................................................................................. 14

8.

BATTERY MAINTENANCE AND CHARGING.................................................................. 15

9.

MAINTENANCE INSTRUCTIONS ..................................................................................... 15

9.1.

M

AINTENANCE

-

G

ENERAL RULES

.................................................................................................15

9.2.

R

OUTINE MAINTENANCE

...............................................................................................................15

9.2.1

Detergent tank filter: cleaning .................................................................................................15

9.2.2

Squeegee blades: replacing......................................................................................................15

9.2.3

Fuses: replacing.......................................................................................................................16

9.3.

R

OUTINE MAINTENANCE

...............................................................................................................16

9.3.1.

Daily operations ......................................................................................................................16

9.3.2.

Weekly operations ...................................................................................................................16

9.3.3.

Six monthly operations............................................................................................................17

10.

TROUBLESHOOTING AND ERROR CODES.............................................................. 18

10.1.

H

OW TO RESOLVE POSSIBLE PROBLEMS

........................................................................................18