We appreciate the confidence you have shown in

JBC by purchasing the desoldering iron DR 5600

Ref. 5600000. It has been manufactured with the

highest standards of quality to ensure reliable

service.

The DR 5600 desoldering iron includes the

following:

-Desoldering iron DR 5600 Ref. 5600000 with

the tip 5600-003 ref. 5600003.

-Spanner for change the desoldering tip Ref.

0780550.

-Instructions manual.

-Transport packaging.

The desoldering iron DR 5600 only works

connected to the following JBC stations:

-AR 5500 desoldering station.

-AM 6000 rework station.

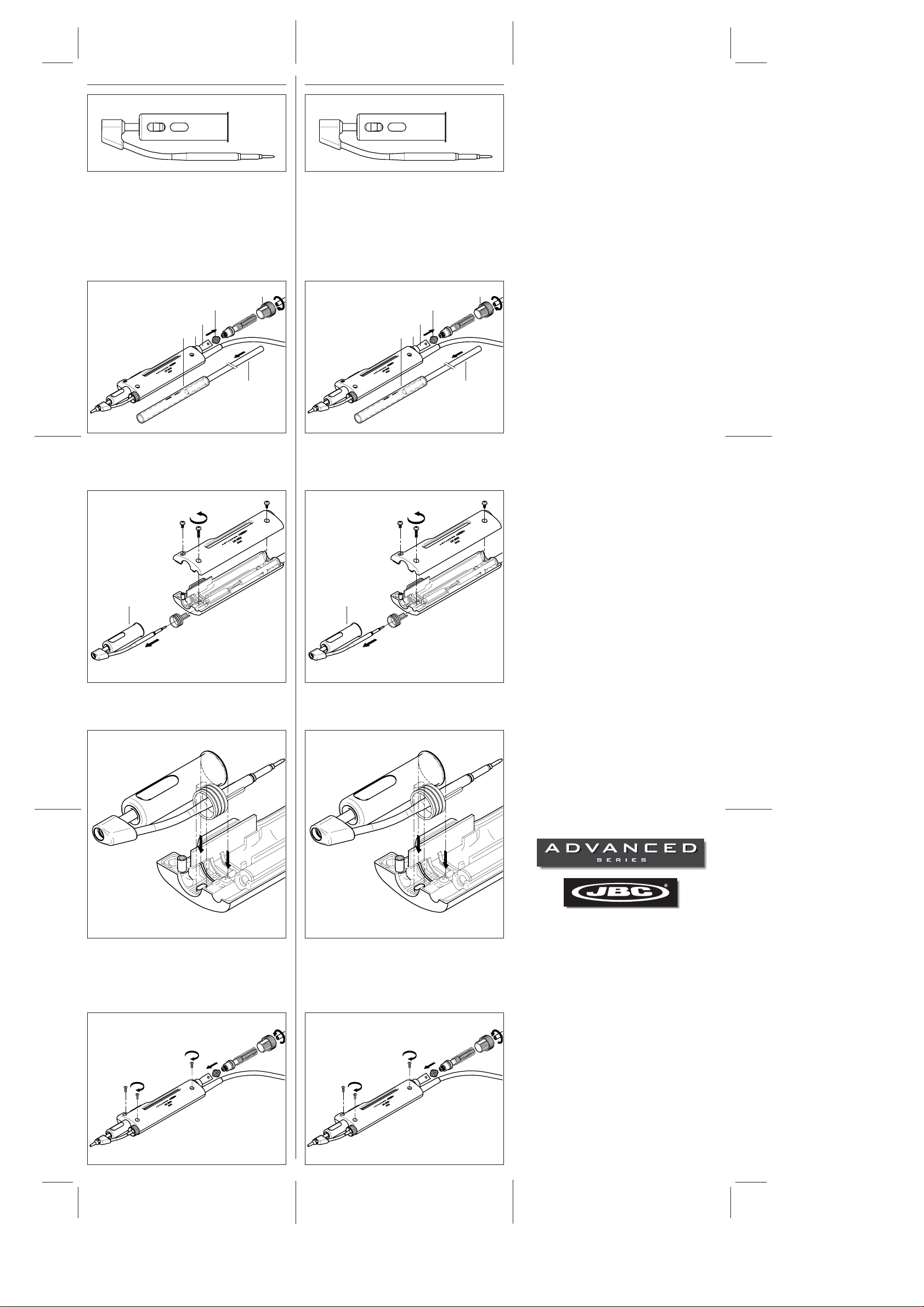

The desoldering iron is connected to the station

followingthebelowprocedure:

The cable connection of the desoldering iron is

connected to the plug in the desoldering iron stand

DR 8500 and the vacuum hose is connected to the

vacuum connection of the station. The cable

connection of the desoldering iron stand is plugged

into the terminal DESOLD of the station. Please

find the connection plan on figure in the rear page.

Desoldering process

Use the tip model with a larger diameter than the

pad to be desoldered, so as to achieve maximum

aspiration and thermal efficiency.

1Apply the desoldering iron tip so that the

component terminal penetrates within its orifice.

2When the solder liquefies, start gently to rotate

the desoldering tip so that the component’s

terminal can be eased away from the sides.

3Press then, not before, the vacuum pump

push-button just long enough to aspirate the solder.

WARRANTY ENGLISH

TheJBC2yearswarranty,guarantees

thisequipmentagainstallmanufacturing

defects, covering the replacement of

defectivepartsandallnecessarylabour.

Warranty doesnotcoverproductwear

due to use or mis-use.

In order for the warranty to be valid,

equipment must be returned, postage

paid, to the dealer where it was

purchasedenclosingthis,fullyfilledin,

sheet.

GARANTIA ESPAÑOL

JBC garantiza este aparato durante 2

años, contra todo defecto de

fabricación,cubriendolareparacióncon

sustitución de las piezas defectuosas

eincluyendolamanodeobranecesaria.

Quedanexcluidasdeestagarantíalas

averías provocadas por mal uso del

aparato y desgaste por uso.

Esindispensableparaacogerseaesta

garantía el envio del aparato al

distribuidordondeseadquirió,aportes

pagados, adjuntando esta hoja

debidamentecumplimentada.

GARANTIE FRANÇAIS

JBC garantit cet appareil 2 ans contre

tout défaut de fabrication. Cela

comprendlaréparation,leremplacement

des pièces défectueuses et la main

d'oeuvrenécessaire.

Lagarantienecouvrepasl’usureliéeà

l’utilisation et à la mauvaise utilisation

dumatériel.

Pour bénéficier de cette garantie il est

indispensabled'envoyerl'appareilchez

le distributeur où il a été acquis, en

ports payés, en joignant cette fiche

dûmentremplie.

1 2 3

DR5600Ref.5600000

Desoldering tip

Heating element

Pushbutton vacuum pump Vacuum hose

Desoldering iron cable

Solder tin deposit Metal

Glass

Change of desoldering tip

This operation should be done while the tip is

hot, at a minimum temperature of 250°C, so that

any tin left inside is in molten state.

-Rest the desoldering iron body in the support

and unscrew the tip to be replaced, with the aid

of the spanner supplied.

-Fit the new tip, and tighten up with the spanner

to achieve a good air tightness.

Ref. 0780550

After pressing the desoldering key there is a

slight delay until the self-contained vacuum pump

stops, this is to make sure that the vacuum

circuit is completely empty.

If any solder remains are left on any terminal after

attempting to desolder it, resolder it with fresh

solder and repeat the desoldering operation.and

replaced if dirty or damaged.

Tip care

-The largest rod that fits in the tip hole should

periodically be passed through in order to

clean the intake tube.

-To clean the tips, use the sponge included

with the stand and check it is lightely moisted.

To emptythesolder tin depositandchangethefilter

For this, the lid needs to be unscrewed and first

the tin deposit and then its spiral must be

removed to clean the inner part of the deposit

with a brush.

-The condition of the filter must be checked

and replaced if dirty or damaged.

-The deposit needs to be inserted with spiral

filter put into place. Then the whole must be

closed by screwing the lid shut.

Solder tin deposits

It can be chosen between two different deposit

types:

-Metal Ref. 0812630.

-Glass Ref. 0812620.

Lid

Brush

Ref. 0786640

Filter Ref. 0780840

Deposit

Spiral

-Do not file the tips or use abrasive tools

which may damage the tip’s protective surface

coating and avoid knocking them about.

-If the tip has been a long time without being

tinned, use a metal brush to remove any dirt

and oxid.

IMPORTANT::

::

: DO NOT press the pushbutton

vacuum pump while tinning the desoldering tip,

as the fumes given off by the flux would quickly

soil the ducts and filter of the air circuit.

-Place the new heating element. Check that

the right extremity of the upper part of the

heating element is inserted in the slot

located inside the body of the desoldering

iron (see drawing hereunder).

-Screw out the body of the desoldering iron.

Open up the body and remove the heating

element.

-Screw in the body of the desoldering iron.

Put the spiral and the filter back into the

deposit. Place the deposit inside the body

of the desoldering iron and screw in the

shut lid.

Lid

Brush

Ref. 0786640

Filter Ref. 0780840

Deposit

Spiral

Heating element

Ref. 5600010

Change of the heating element of the desoldering

iron (Ref. 5600010)

-To realize this operation, the lid needs to

be unscrewed and first the tin deposit and

then its spiral and filter must be removed

to clean the inner part of the deposit with a

brush.