Place the �n on the gears

Your sta�ons is being updated

Do you want to update firmware?

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

Place the �n on the gears

Your sta�ons is being updated

Do you want to update firmware?

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

1

2

Inlet

Nozzle

Wire

Guidance

Solder Wire Loading

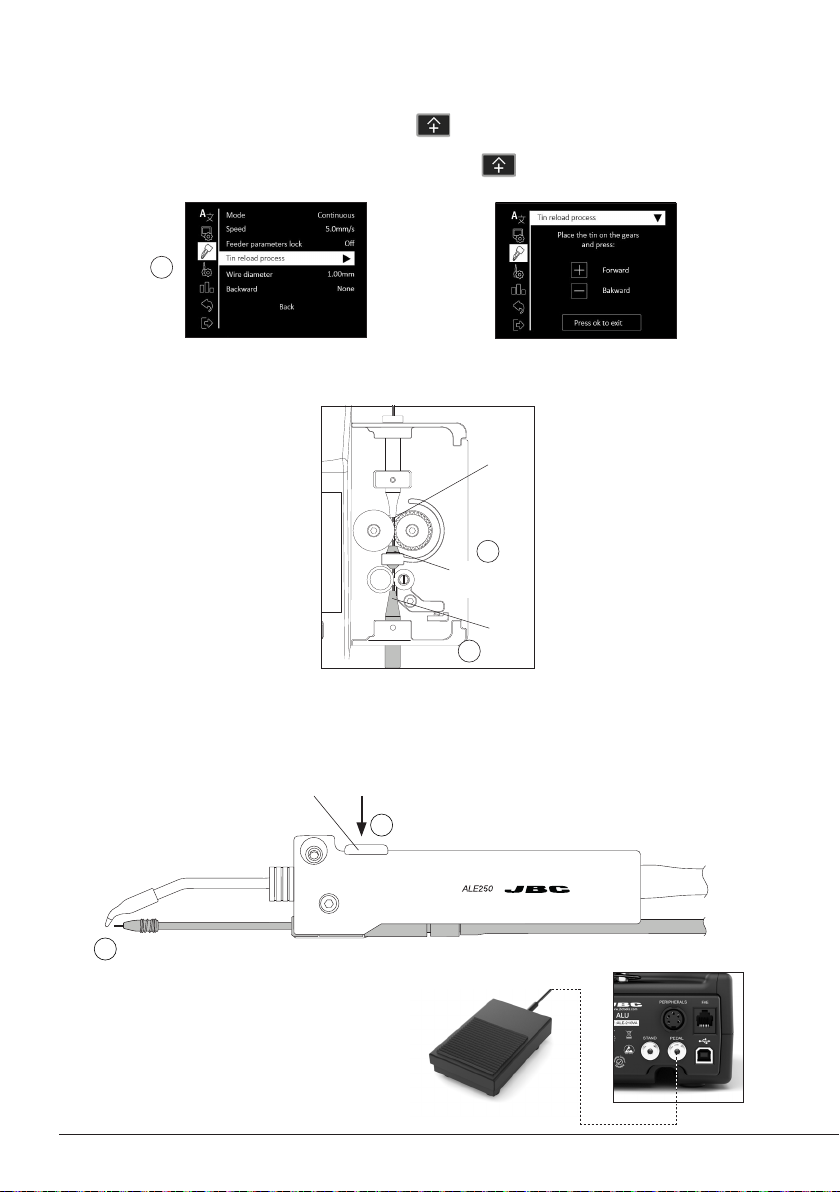

Pass the solder wire through the wire guidance

and introduce the solder wire into the inlet nozzle

(1) until it reaches the wheels (2).

Make sure the wire passes through the intermediate nozzle (3) and enters the guide tube (4).

Guide

Tube

Wheels

Intermediate

Nozzle

4

3

Acces to Main Menu by , select “Feeder Settings” (1) and then “Wire Diameter” (2) to adjust the

value to the current solder wire diameter.

12

Select “Tin Reloaded Process” (1) and then use to feed the solder wire and advance until it

comes out of the outlet nozzle. If needed, carefully push the wire until it gets locked in between the

rotating wheels for the wire to start moving forward. Keep pressed and after a while, the wire

will advance faster.

Main Menu Screen

Wire

1

AP250

AL250

AL250

SF280

SF250

ALE250

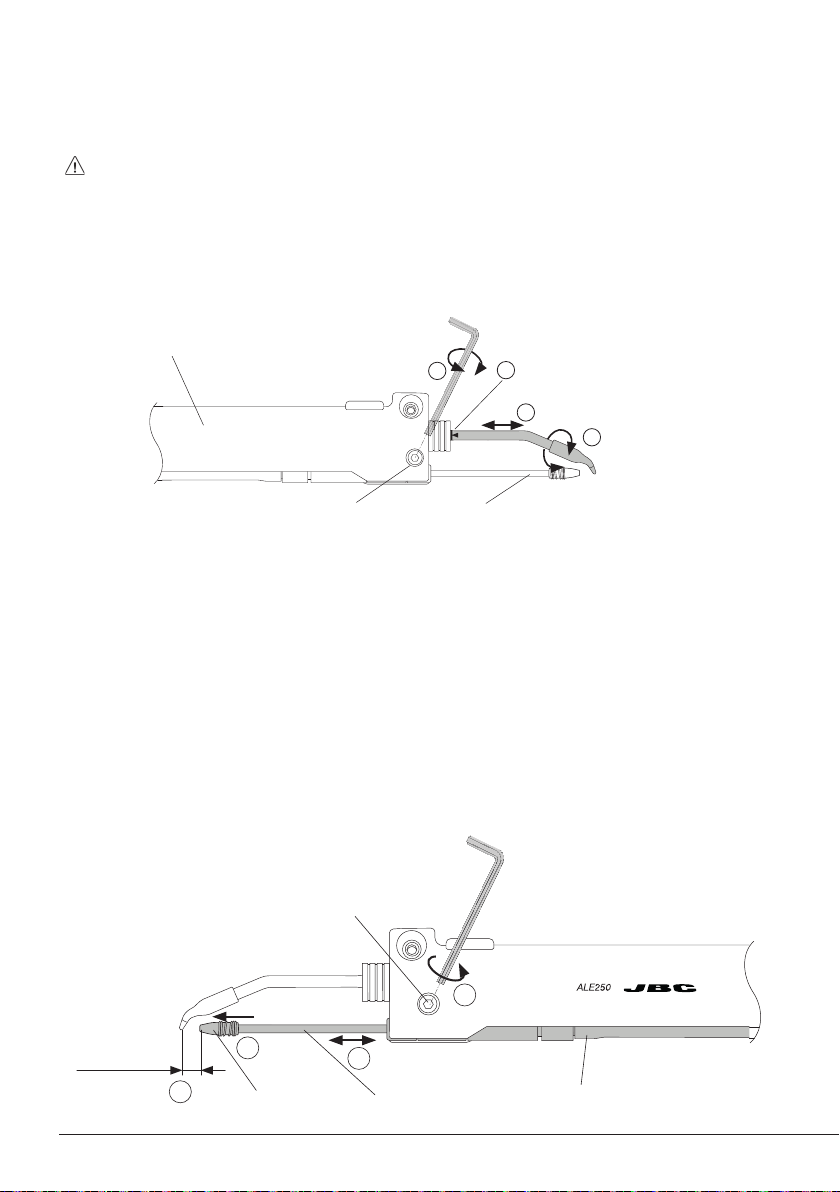

Solder Wire Dragging Button

Forward the solder wire by pushing the dragging button (1) until the wire comes out of the tip (2).

1

2

Solder Wire Feeding

To feed the solder wire, alternatively, the pedal

P405 can be used. The pedal should be plugged

in at the rear of the feeder control unit into the

pedal connector.

9

Solder Wire Unloading

With Solder Wire Perforation

To unload solder wire with perforation that has already passed through the guide tube, cut the wire

between the wire guidance and the inlet nozzle (1). To extract the wire out of the tube, hold the tool on

your hand and press until the wire stops moving forward. Grasp the wire coming out of the outlet

nozzle with a plears and pull from it until it is completely out.

Without Solder Wire Perforation

When using a kit without solder wire perforation, press until the wire is completely wound to

unload the solder wire. It is best to rotate the reel by hand as the wire is being pulled back in order to

keep it neatly arranged on the reel.

Or, If preferred, proceed as described above for perforated solder wire unloading.

Place the �n on the gears

Your sta�ons is being updated

Do you want to update firmware?

EARTH FUSE F1.25 A

USE ONLYWITH A 250 V FUSE

EARTH FUSE F1.25 A

Solder Wire

Wire Winding Direction

Place the �n on the gears

Your sta�ons is being updated

Do you want to update firmware?

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

Inlet Nozzle

Wire Guidance

1

40 mm

50 mm

60 mm

80 mm

100 mm

130 mm 130 mm

para manuales - color gris

200 mm

300 mm