666

JBC Net

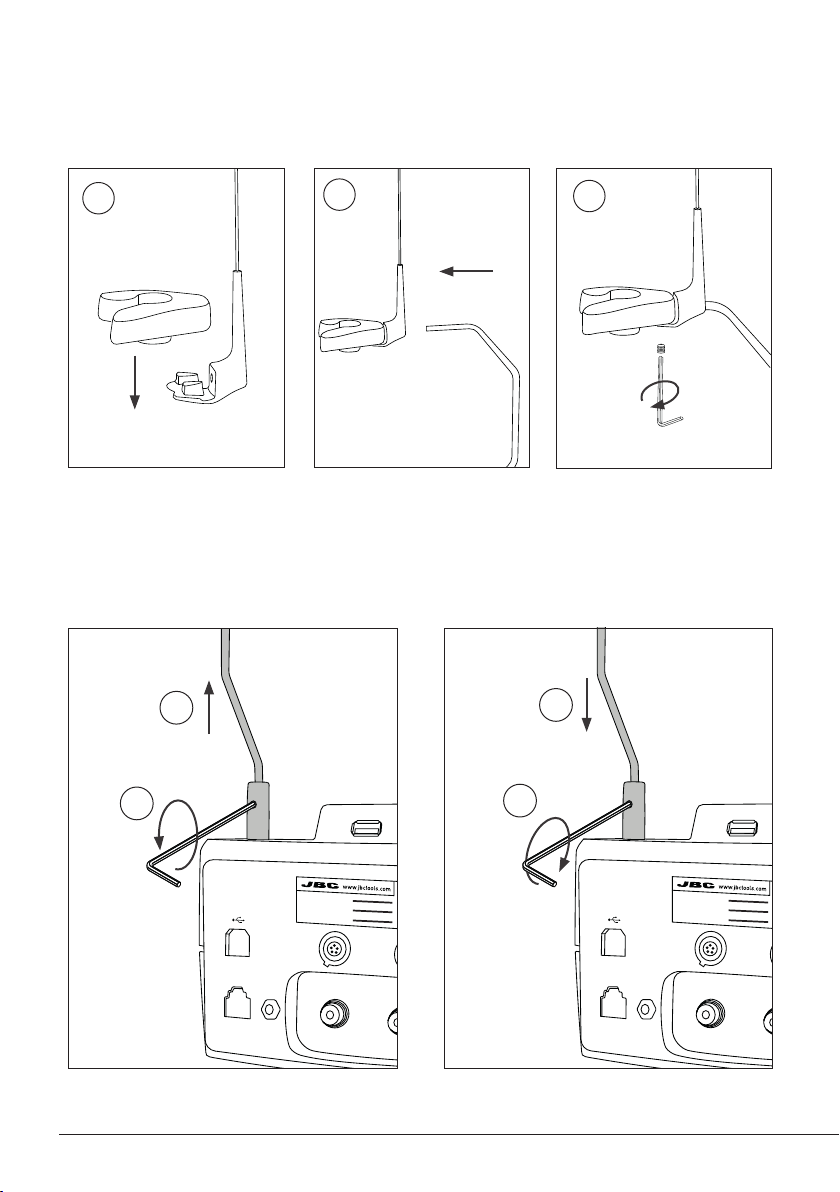

Export graphics

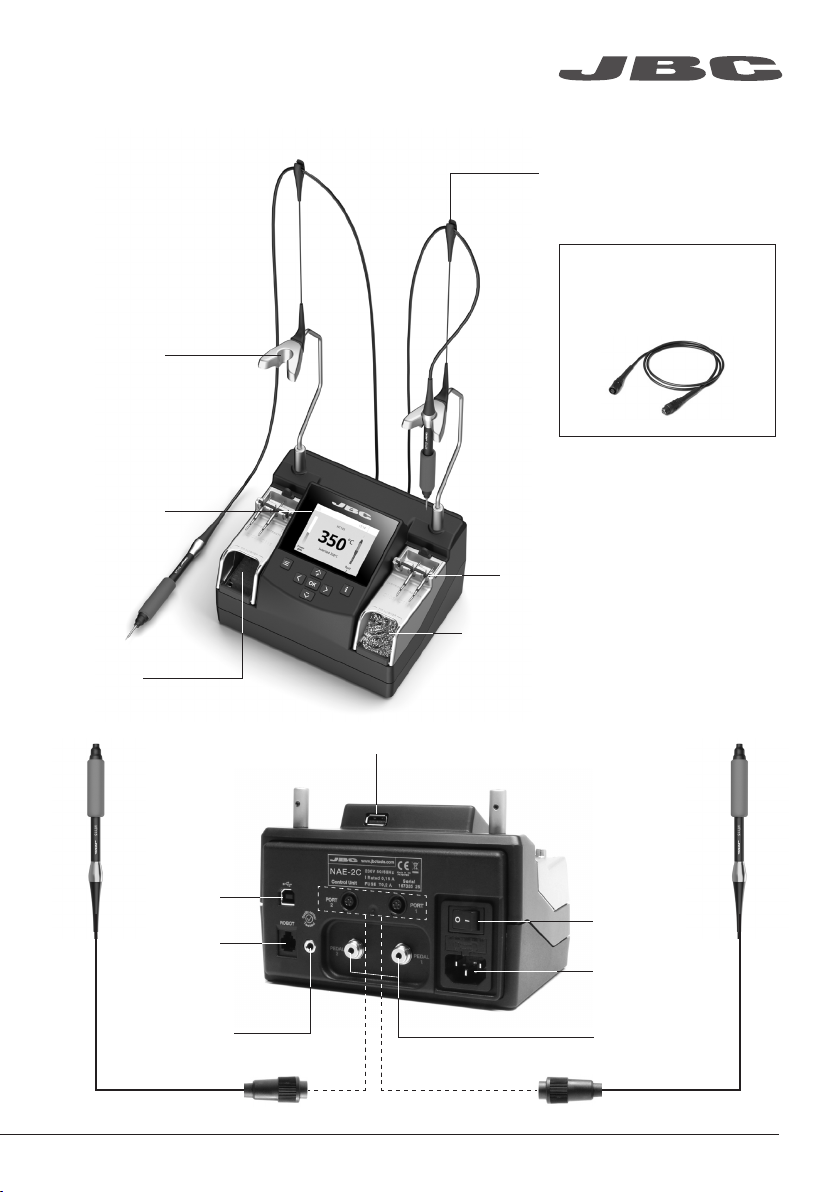

Insert a USB flash drive into the

USB-A connector to save your

soldering process in csv format.

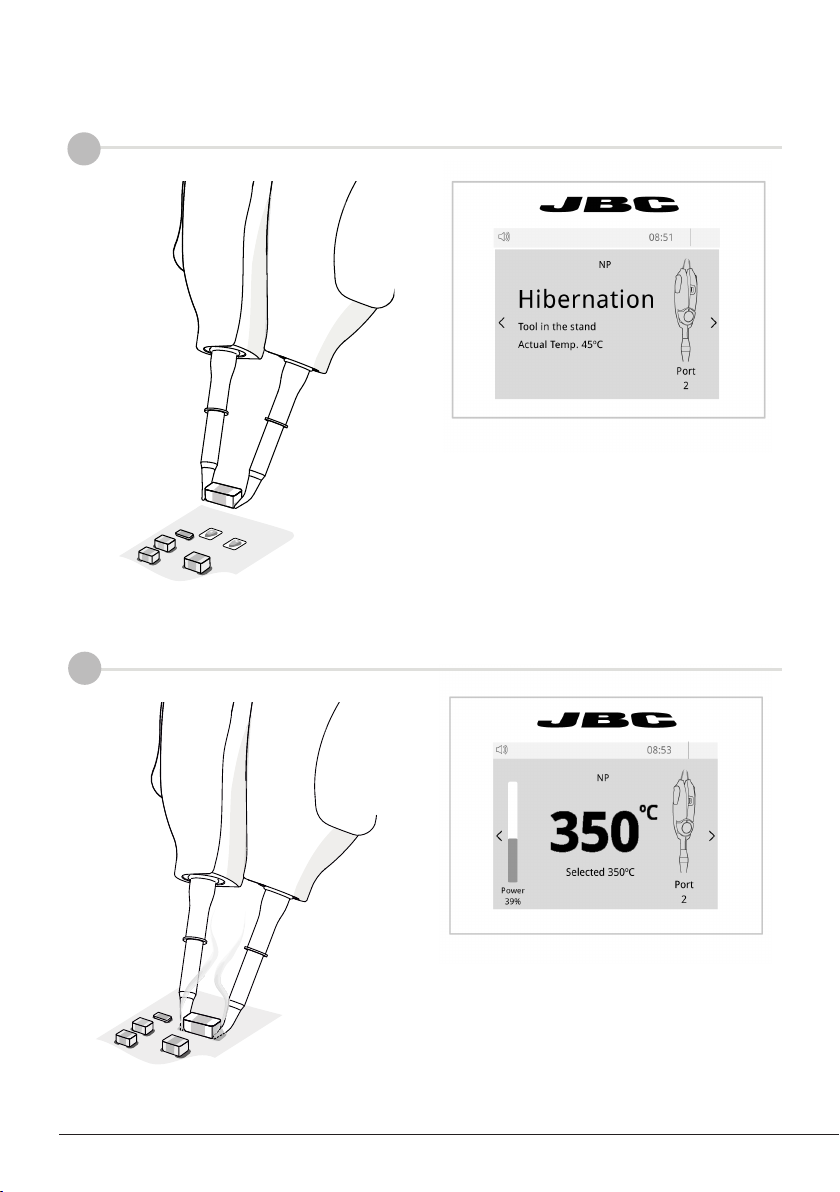

Profiles

Advanced Functionalities

It provides detailed graphics of tip temperature and power delivery in real time during

solder joint formation for analysis purposes. This helps you decide how to adjust your

process or which tip to use to obtain the best quality soldering.

Graphics

Get greater quality and control in your production.

Manage your whole soldering process remotely in real time.

For more information see www.jbctools.com/webmanager.html.

Designed to avoid thermal shock when soldering Ceramic Chip components like

MLCC, this new and unique feature allows controlling the heating ramp up rate of the

tool to gradually increase the temperature of the component through all the phases of

the soldering process. Up to 25 fully configurable soldering profiles can be stored.

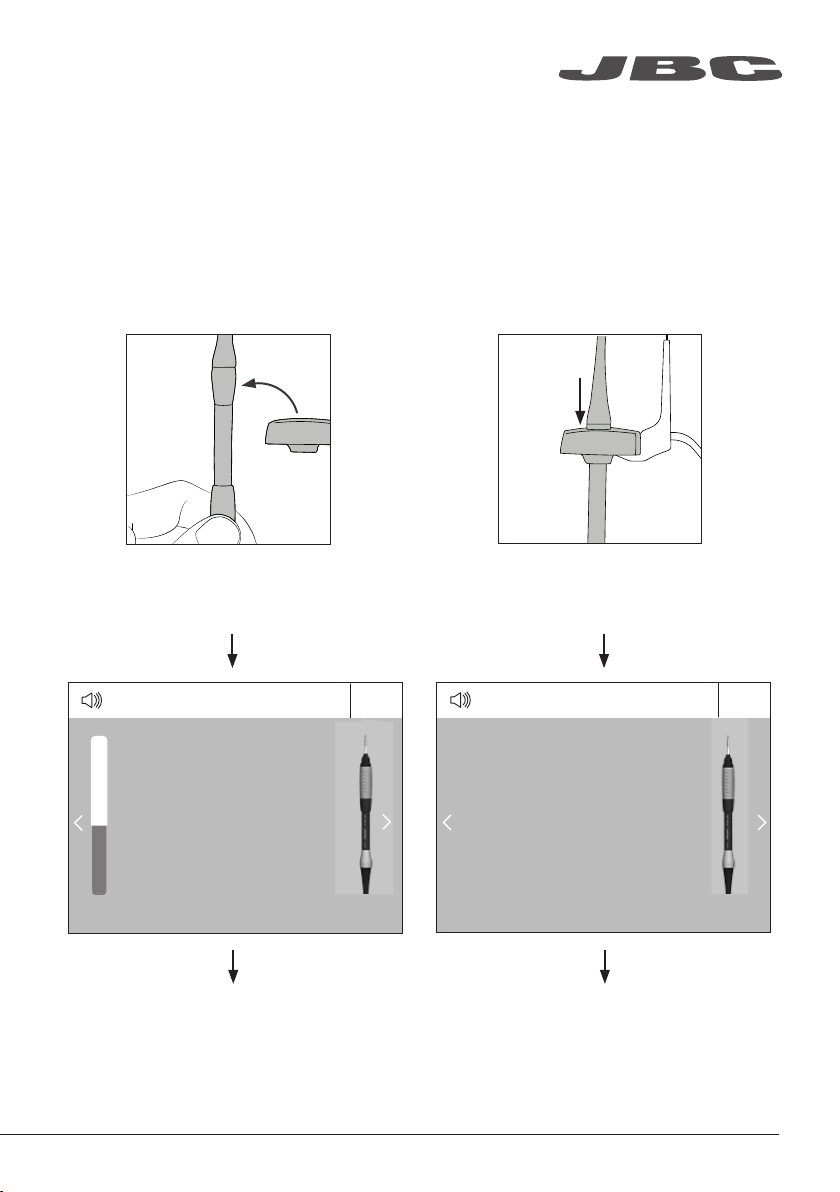

USB flash drive is connected.

Station is controlled by a PC.

Station is controlled by a robot.

System notifications

Station software update.

Press INFO to start the process.

Warning.

Press INFO for failure description.

Error.

Press INFO for failure description,

the type of error and how to proceed.

The following icons will be displayed on the screen’s status bar.

Station update

Download the JBC Update File from

www.jbctools.com/software.html

Insert the USB flash drive with the

file downloaded to the station.

Files

Update