Operator’s Manual JM 2040

10

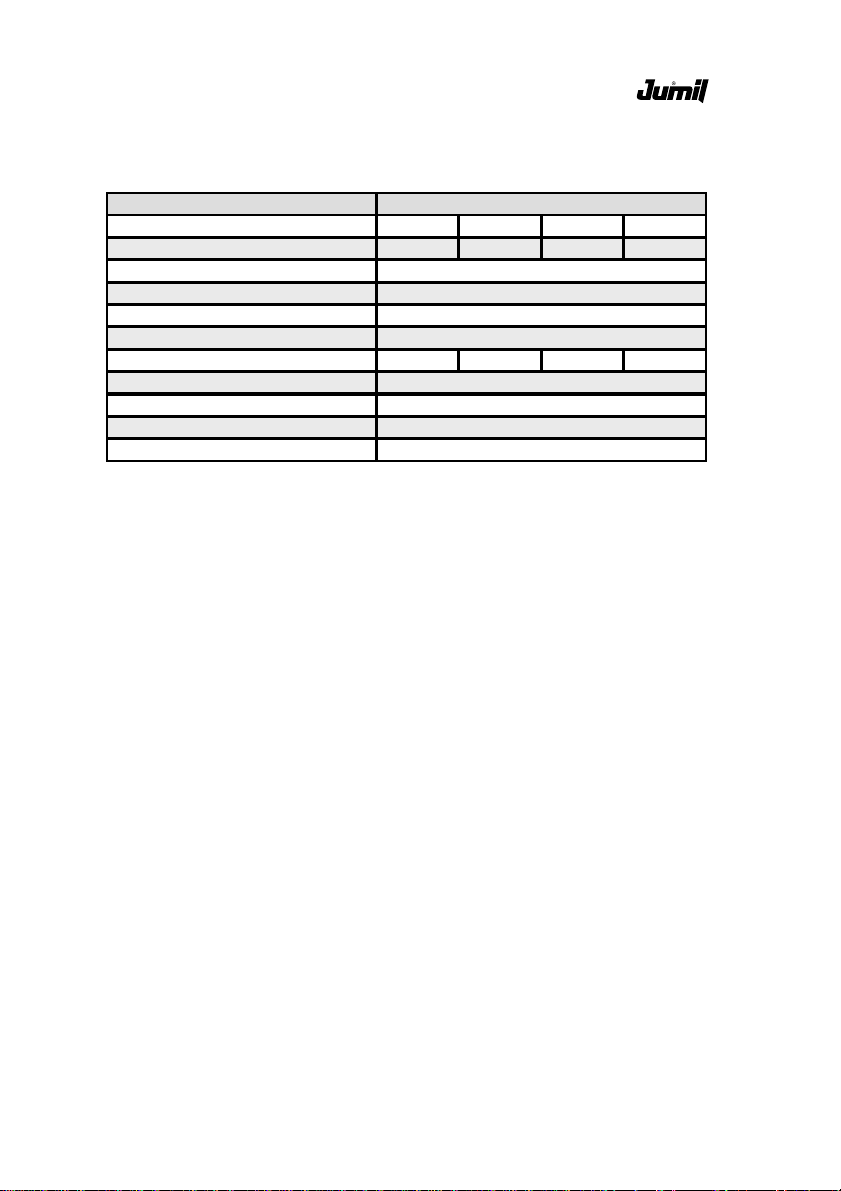

5.1 - Discs and Wedges

Forthe seeddistributionJumil usesthehorizontal drilleddiscsystem,

oflarger precision due to the unique characteristics of project.

JUMIL possesses several discs for be used in agreement with the

type of culture and/or seed size to be used.

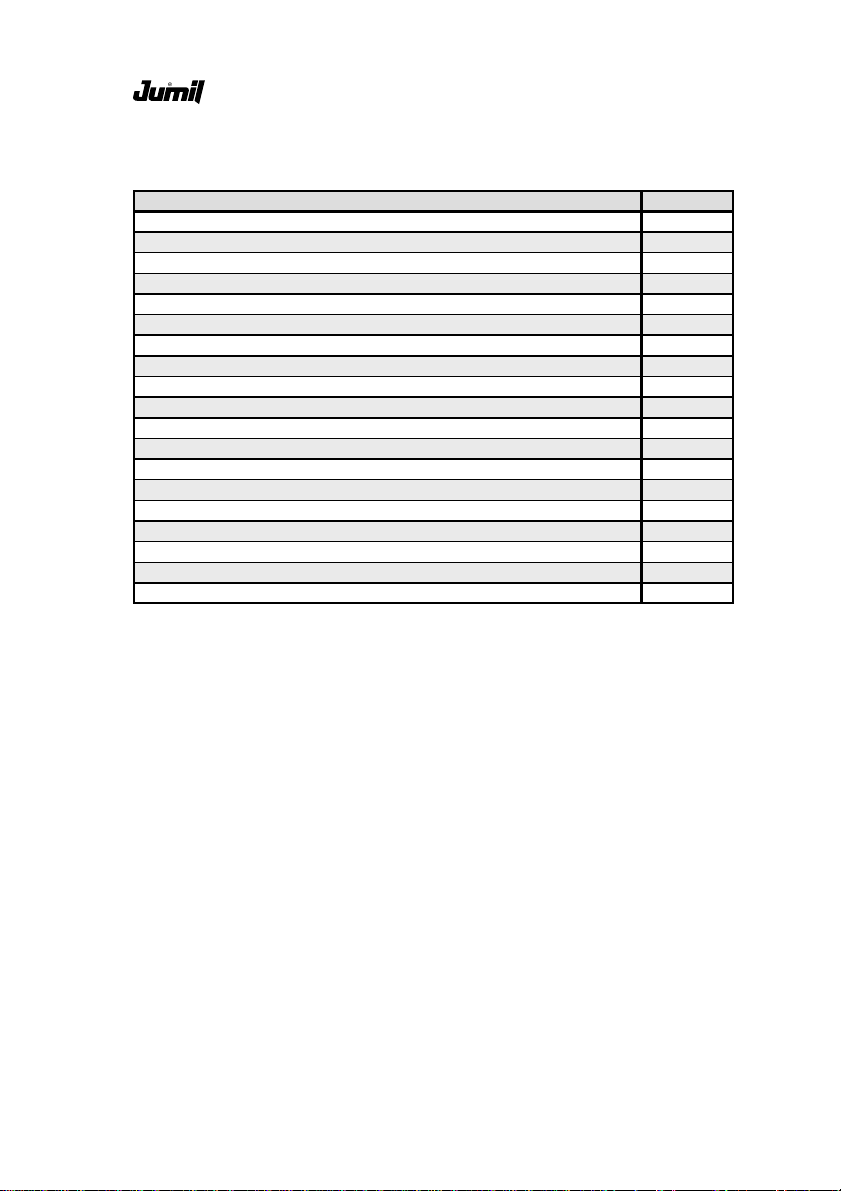

DESCRIPTION CODE

COTTON DISC 64FXE4,5F6,5X11,5 27.10.058

COTTON DISC 64FXE4,5XF5,5X10,5 27.10.057

COTTON DISC WITHOUT LINTER 40FXE5,0 27.18.607

RICE DISC 22FXE4,0XF14,0 27.10.063

RICE DISC 22FXE5,5XF12,0 27.10.142

RICE DISC 22FXE5,5XF13,0 27.28.699

RICE DISC 24FXE4,5XF14,0 27.10.064

JALO BEAN DISC 36FSXE6,5XF9,5X16,5 **27.28.711

BEAN DISC 41FSXE5,5XF7,5X13,5 27.28.545

BEAN DISC 72FDXE5,5XF8,0X12,0 27.10.072

BEAN DISC 80FDXE4,5XF7,0X10,0 27.10.071

SUNFLOWER DISC 20FSXE3,5XF5,0X11 27.28.591

SUNFLOWER DISC 20FSXE3,5XF6,0X12 27.28.590

SUNFLOWER DISC 20FSXE4,0XF7,5X15 27.10.148

SUNFLOWER DISC 20FSXE4,0XF8,5X17 27.10.161

SUNFLOWER DISC 24FSXE3,5XF5,0X11 27.28.566

SUNFLOWER DISC 24FSXE3,5XF6,0X12 27.28.567

PLAIN DISC E4,5 27.28.701

PLAIN DISC FOR MAIZE 24FXE4,5 27.28.709

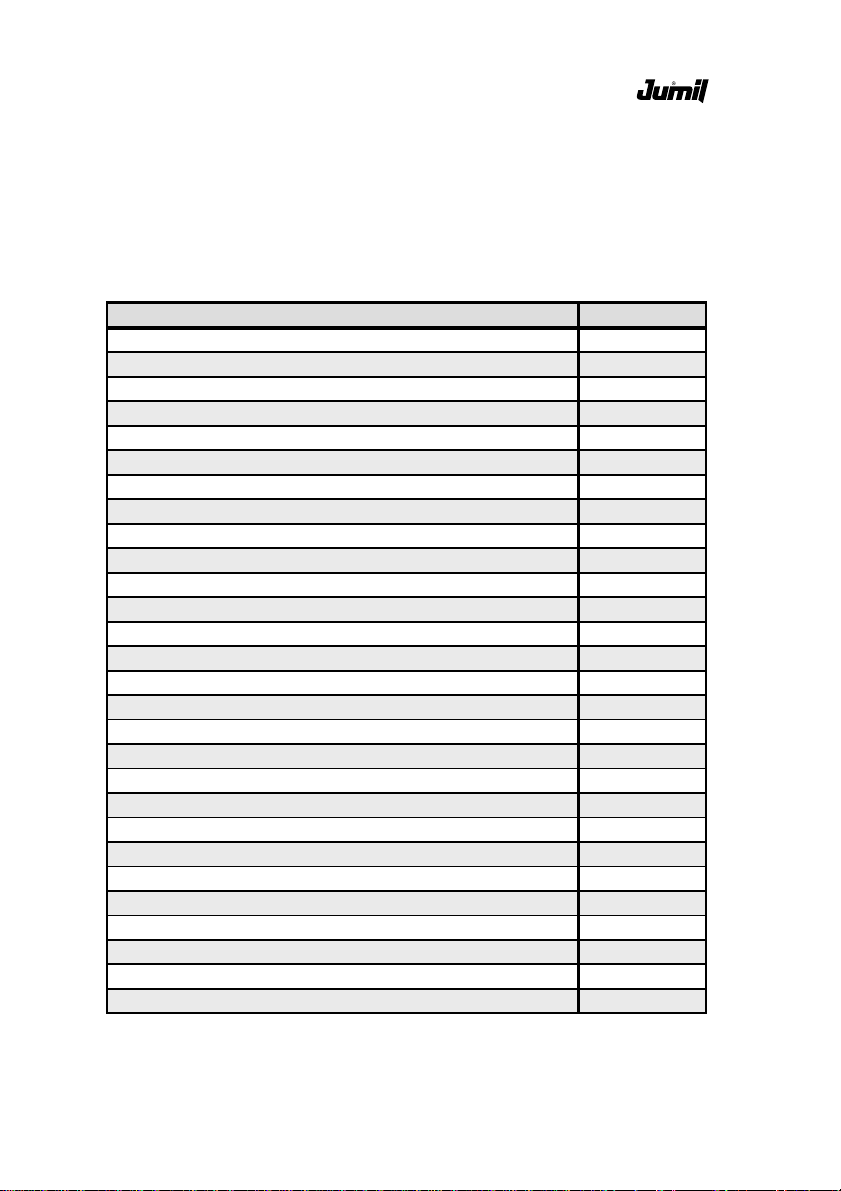

MAIZE DISC 22FXE4,0XF13,0 27.10.143

MAIZE DISC 22FXE4,0XF14,0 27.10.139

MAIZE DISC 22FXE7,5XF12,0 *27.10.141

MAIZE DISC 24FXE4,0XF10,5X15,0 27.28.596

MAIZE DISC 24FXE4,0XF11,0X16,0 27.28.595

MAIZE DISC 24FXE4,0XF9,0X13,8 27.28.577

MAIZE DISC 24FXE4,0XF9,5X14,0 27.28.597

MAIZE DISC 24FXE4,5XF10,5X14,0 27.28.578

MAIZE DISC 24FXE4,5XF13 27.28.694