JUMO 404304 Series User manual

Other JUMO Transmitter manuals

JUMO

JUMO SIRAS P21 AR User manual

JUMO

JUMO Wtrans p User manual

JUMO

JUMO 4AP-30 User manual

JUMO

JUMO dTRANS T07 User manual

JUMO

JUMO dTRANS p02 DELTA User manual

JUMO

JUMO dTRANS p02 DELTA User manual

JUMO

JUMO SIRAS P21 DP User manual

JUMO

JUMO JUMO dTRANS p20 DELTA User manual

JUMO

JUMO dTRANS T02 Ex User manual

JUMO

JUMO TRANS T06 Junior User manual

JUMO

JUMO B 707025.0 User manual

JUMO

JUMO JUMO dTRANS p20 DELTA User manual

JUMO

JUMO CTI-500 User manual

JUMO

JUMO B 90.7027.1 User manual

JUMO

JUMO dTRANS T09 AS User manual

JUMO

JUMO 907021/10 User manual

JUMO

JUMO dTRANS T05 User manual

JUMO

JUMO CTI-500 Use and care manual

JUMO

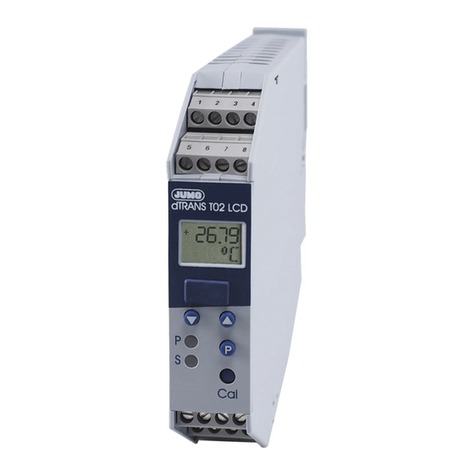

JUMO dTRANS T02 LCD User manual

JUMO

JUMO dTRANS T06 Ex User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide