6

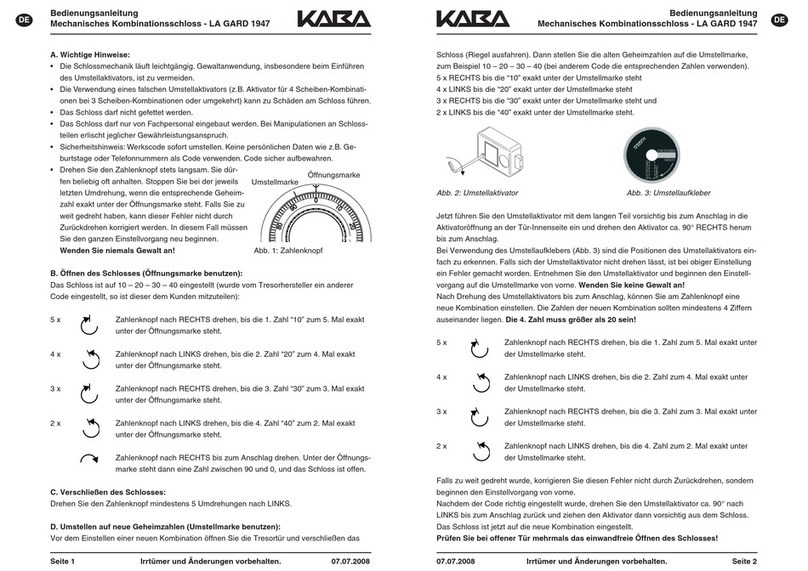

D. INSTALLING THE SPINDLE

D-1 For doors ranging in thickness from 1 3⁄8"

(35 mm) to 1 7⁄8" (48 mm) use the shorter

spindle (supplied) and align as shown.

D-2 For doors ranging in thickness from 2"

(51 mm) to 2 1⁄2” (64 mm) use the longest

spindle (supplied) and align as shown.

D-3 Make sure the spindle matches the picture

shown depending on the hand of the lock.

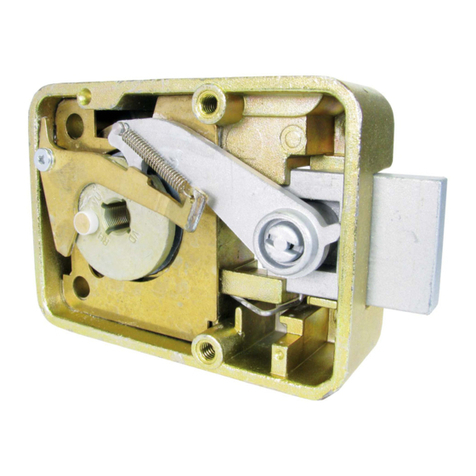

E. INSTALLING THE L CK

E-1 Place the rubber gaskets around the lock

body with the lock body sitting into the

recessed portion of the gasket. Assure

the holes in the back of the lock and the

gasket match.

E-2 If using the cover plates (supplied), an

additional hole must be drilled in the cover

plates before the installation continues

(See back of cover plate).

E-3 Once additional hole has been drilled, place the cover plate on the back of

the lock between the gasket and the door.

E-4 For doors ranging in thickness from 1 3⁄8”( 35 mm) to 1 5⁄8”( 41 mm), use

the shorter mounting screws (supplied) and align as shown

E-5 For doors ranging in thickness from 1 3⁄4" (44 mm) to 2” (51 mm), use the

medium mounting screws (supplied) and align as shown.

E-6 For doors ranging in thickness from 2 1⁄8" (54 mm) to 2 1⁄2” (64 mm), use

the longest mounting screws (supplied) and align as shown.

Note: If cover plates are used, it may be necessary to use the next size

screw to mount the lock.

E-7 Hold the outside and inside units on the door with the spindle in the

proper position.

E-8 Finger-tighten the (2) mounting screws, assuring the lock is vertical and

sitting flush against the door.

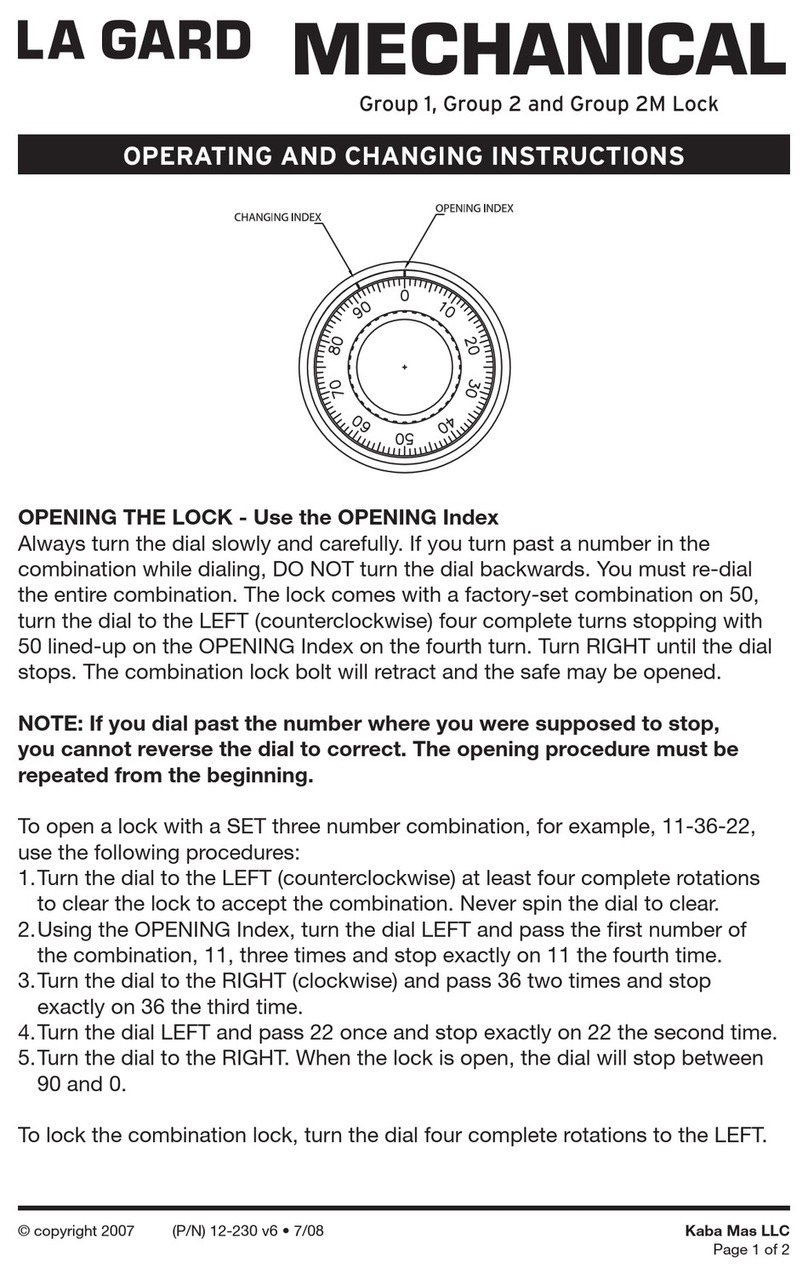

Viewed from

the outside

Door hung on right

spindle should

engage the latch

as above

Door hung on left

spindle should

engage the latch

as above

Note: Assurance that the proper spindle is

used is extremely critical. If the wrong

spindle is used, binding or lockout can occur.

The door thickness including gaskets and trim plates can not exceed 2 1⁄2"

(64 mm).