7

SAFETY WARNING

This analyser must only be used in well-ventilated locations by trained and competent

persons after due consideration of all the potential hazards and with regard to local and

National regulations and guidelines.

The analyser extracts combustion gases that may be toxic in relatively low concentrations.

These gases are exhausted from the bottom of the instrument.

Users or portable gas detectors are recommended to conduct a “bump” check before

relying on the unit to verify an atmosphere is free from hazard.

A “bump” test is a means of verifying that an instrument is working within acceptable limits

by briefly exposing to a known gas mixture formulated to change the output of all the

sensors present. (This is different from a calibration where the instrument is also exposed

to a known gas mixture but is allowed to settle to a steady figure and the reading adjusted

to the stated gas concentration of the test gas).

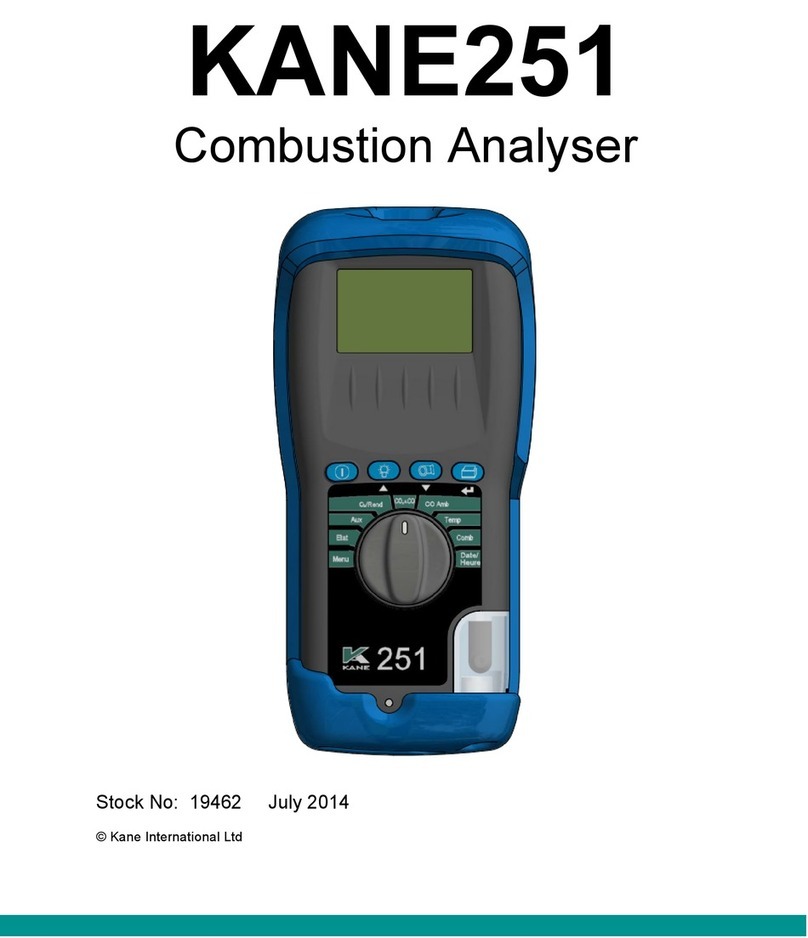

KANE9206 OVERVIEW

The KANE9206 is broadly based on the KM9106 and whilst retaining many of its core

features has been significantly enhanced. The most visible difference is the large

graphical display on the handset. Up to 15 lines of text/data can be displayed. The

handset links to the main analyser unit using wireless communications or the normal

cable. It also has a USB connector to link to a PC via a cable and has an infra-red output

to link to the portable Kane KMIRP-2 printer.

The main analyser unit also contains significant enhancements over the KM9106.

STANDARD FEATURES:

19301 Battery charger

18277 UK mains lead

18276 EU mains lead

18275 US mains lead

19332 Instruction manual

Kane 'LIVE' software download from Kane website

HANDSET: KBHS

Wireless and cable connectivity to analyser unit.

Wireless and USB connectivity to PC

GPS location

IR connectivity to Kane IRP portable printers

Monster data storage memory (64k records)

Graphical display with choice of large or small fonts.

Battery rechargeable via main unit or mains charger