Lancaster® Auditorium Seating with Power & Data

Assembly Instructions

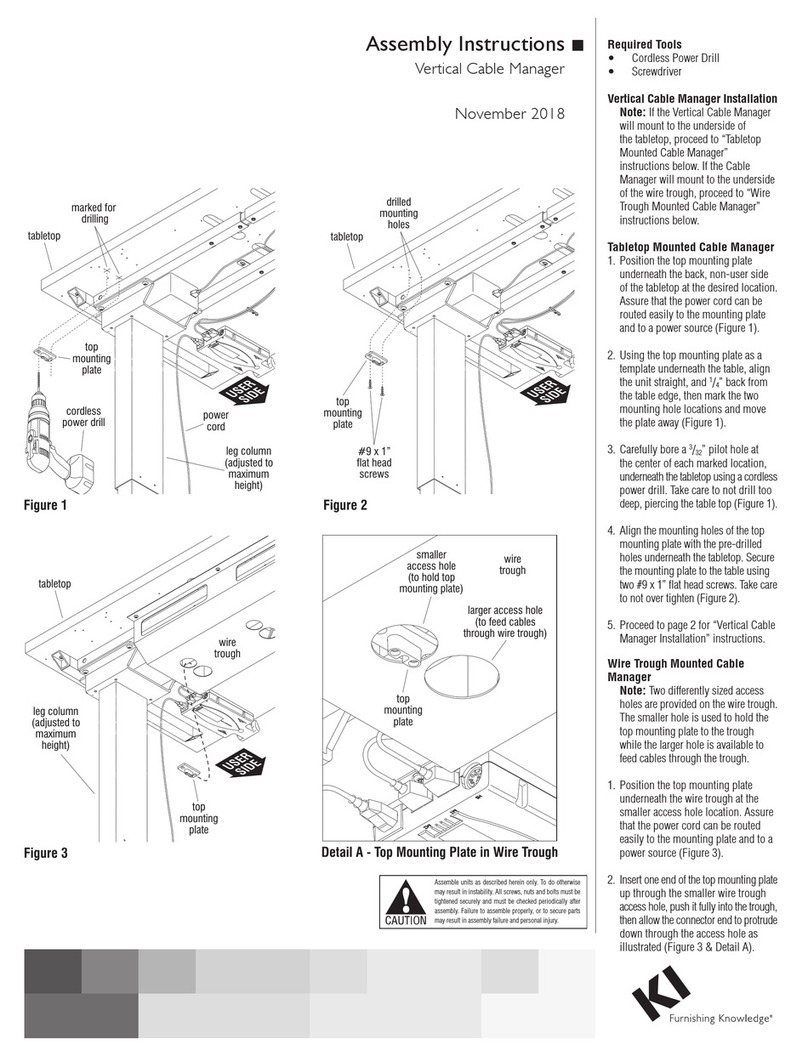

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

1

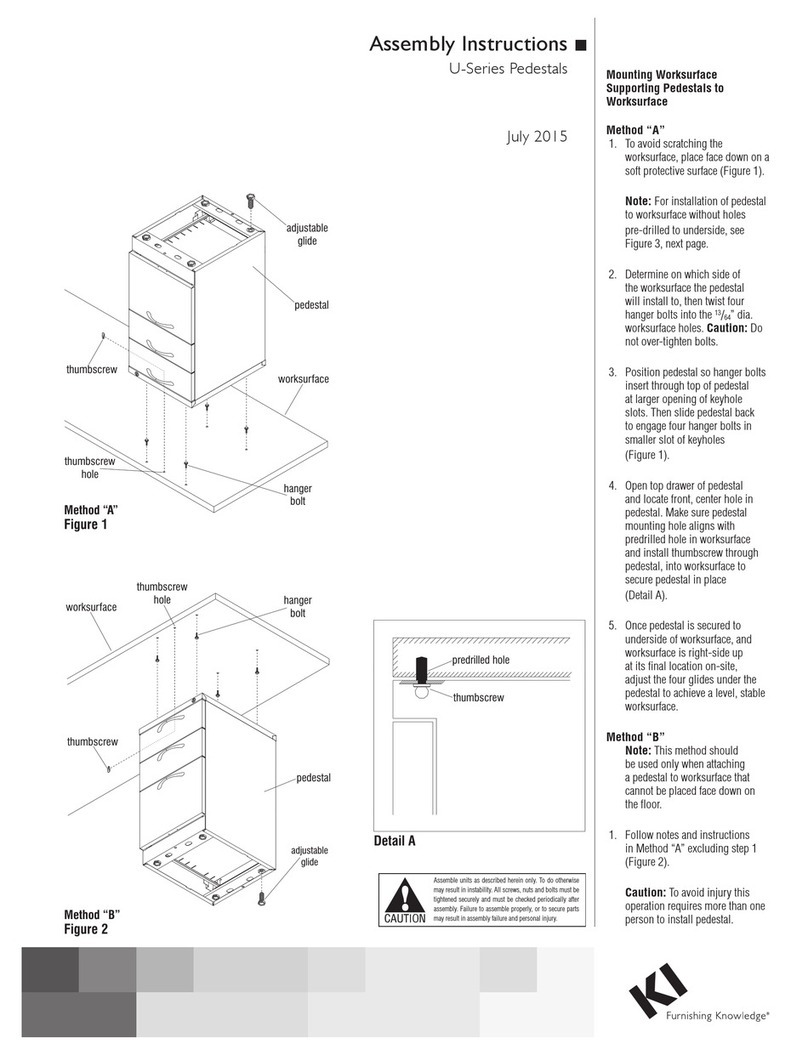

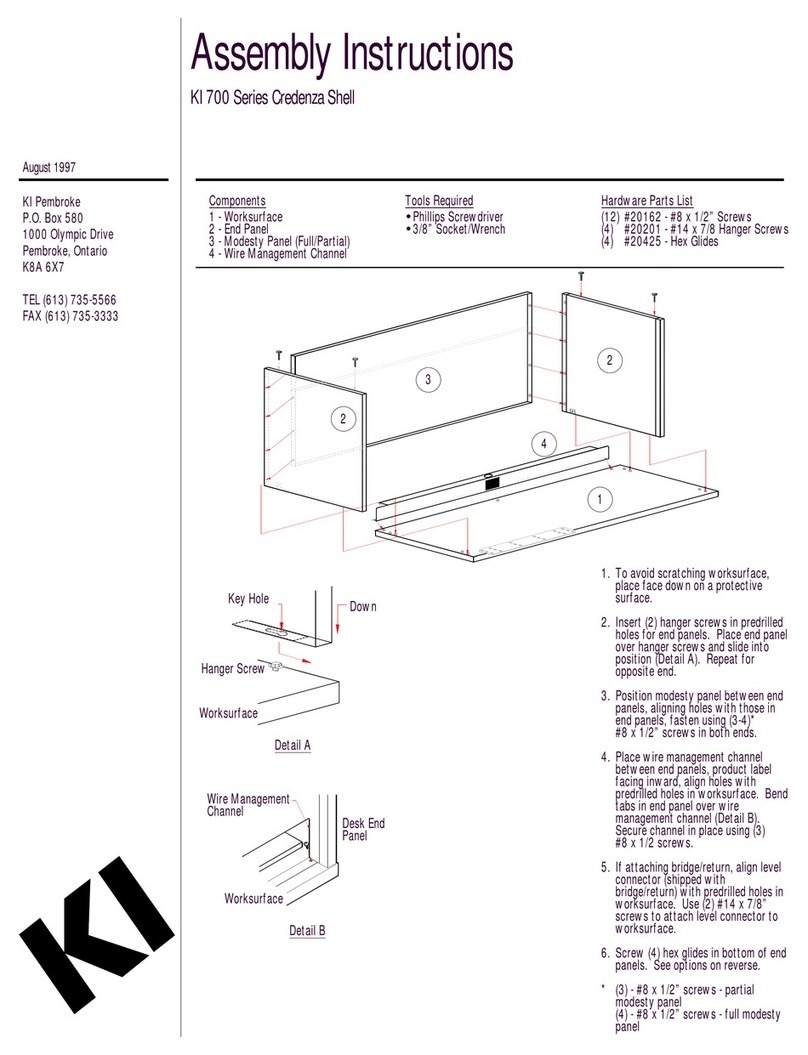

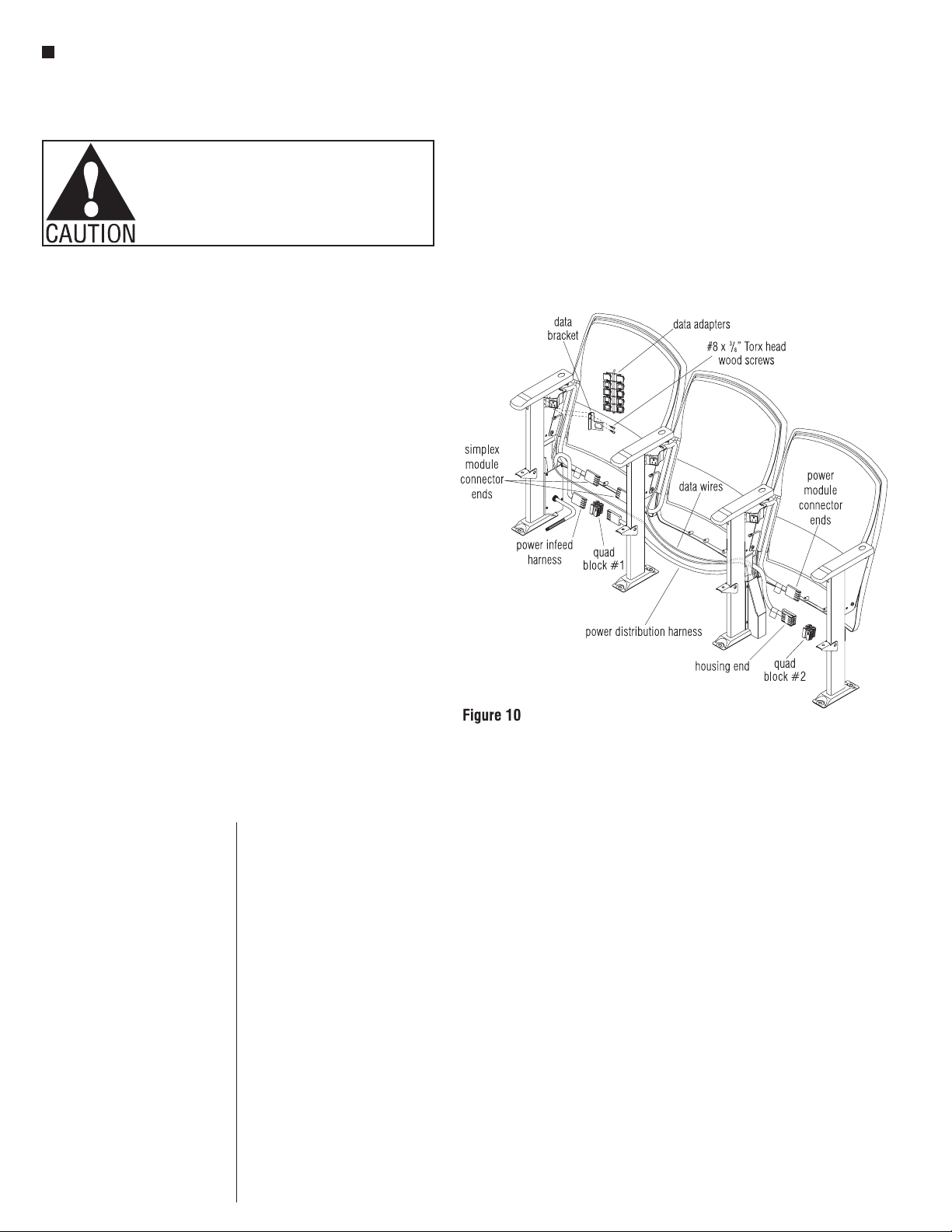

11. Attach power & data modules,

electrical components, data

wires and data jacks (optional).

Note: If unit is powered, the end

panel is installed at the same time

as the above items.

12. Attach and route the power

& data infeed connections

(optional).

13. Attach side covers (required with

power & data or optional without

power & data).

14. Attach end panel (required with

power & data or optional without

power & data).

15. Install the seats.

16. Tighten floor anchors.

17. Install ADA removable bases

(optional).

Note: ADA bases are not

available with power & data.

18. Mount row and seat numbering

(optional).

19. Clean product and site.

20. Walk through with installation

crew to assure the product has

been installed per Lancaster

Auditorium Seating Assembly

Instructions and space-planning

layout.

21. Perform final walk through with

the customer. Receive sign-off.

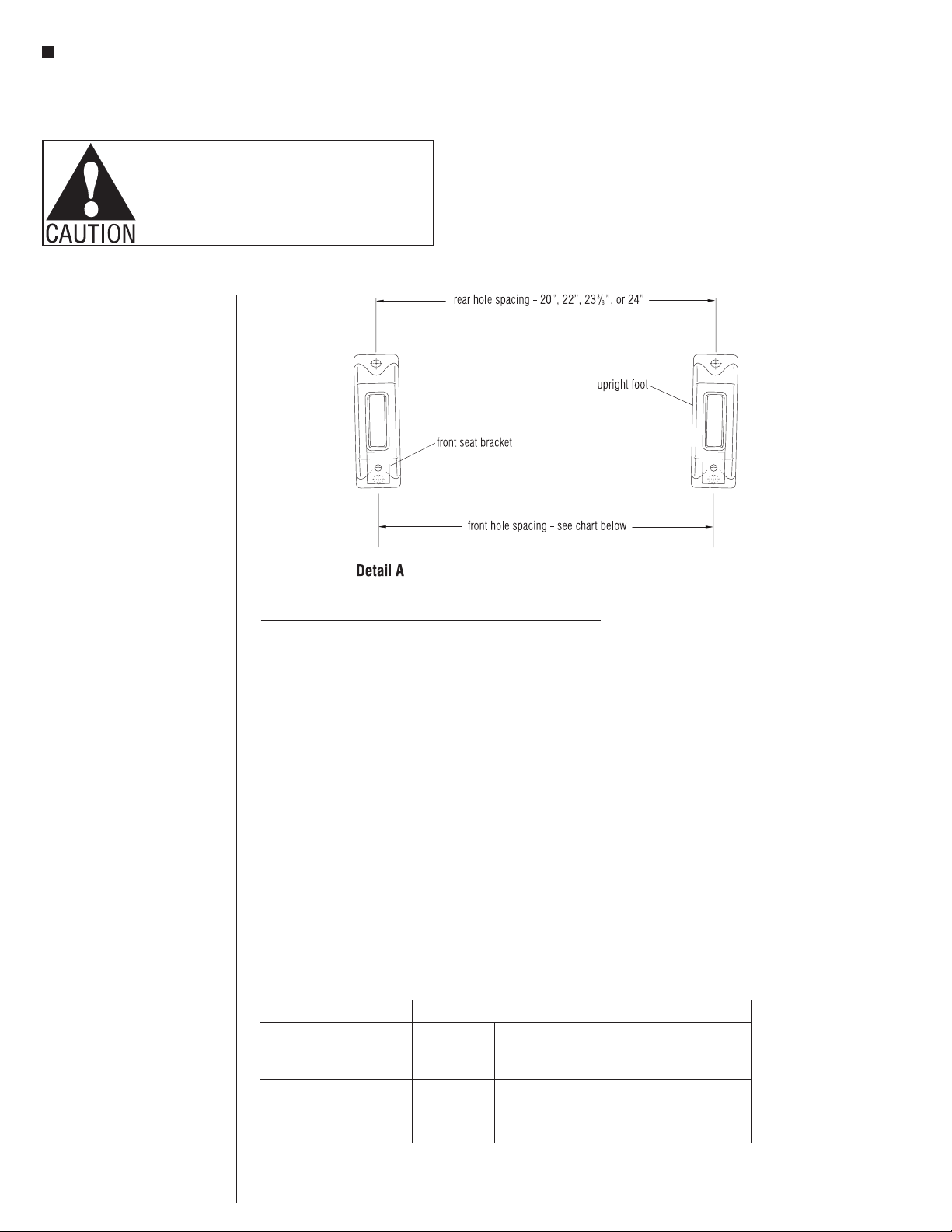

Note: Dimensional spacing

referenced is centerline to

centerline unless otherwise noted.

Concrete Floors

• 5⁄16 -18 or 3⁄8-16 grade 5

expansion anchors

• Standard flat washers, plated

• LockTite (red) thread lock or

equal

• Two screw assemblies

required per upright

Note: Floor-mounting fasteners are

not provided.

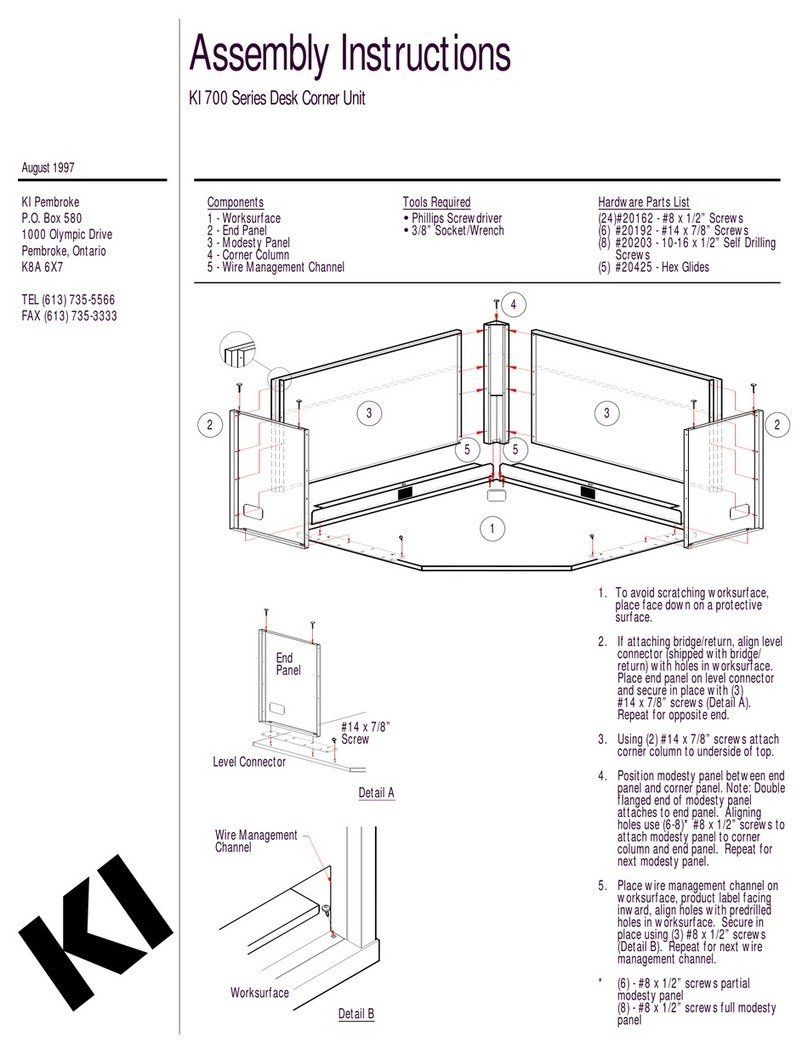

Steps For Installation

1. Read and review Lancaster

Auditorium Seating Assembly

Instructions.

2. Review space-planning layouts.

3. Review job site and verify

field conditions.

4. Verify floor structural

conditions.

5. Stage product for installation.

6. Locate and mark layout

reference points.

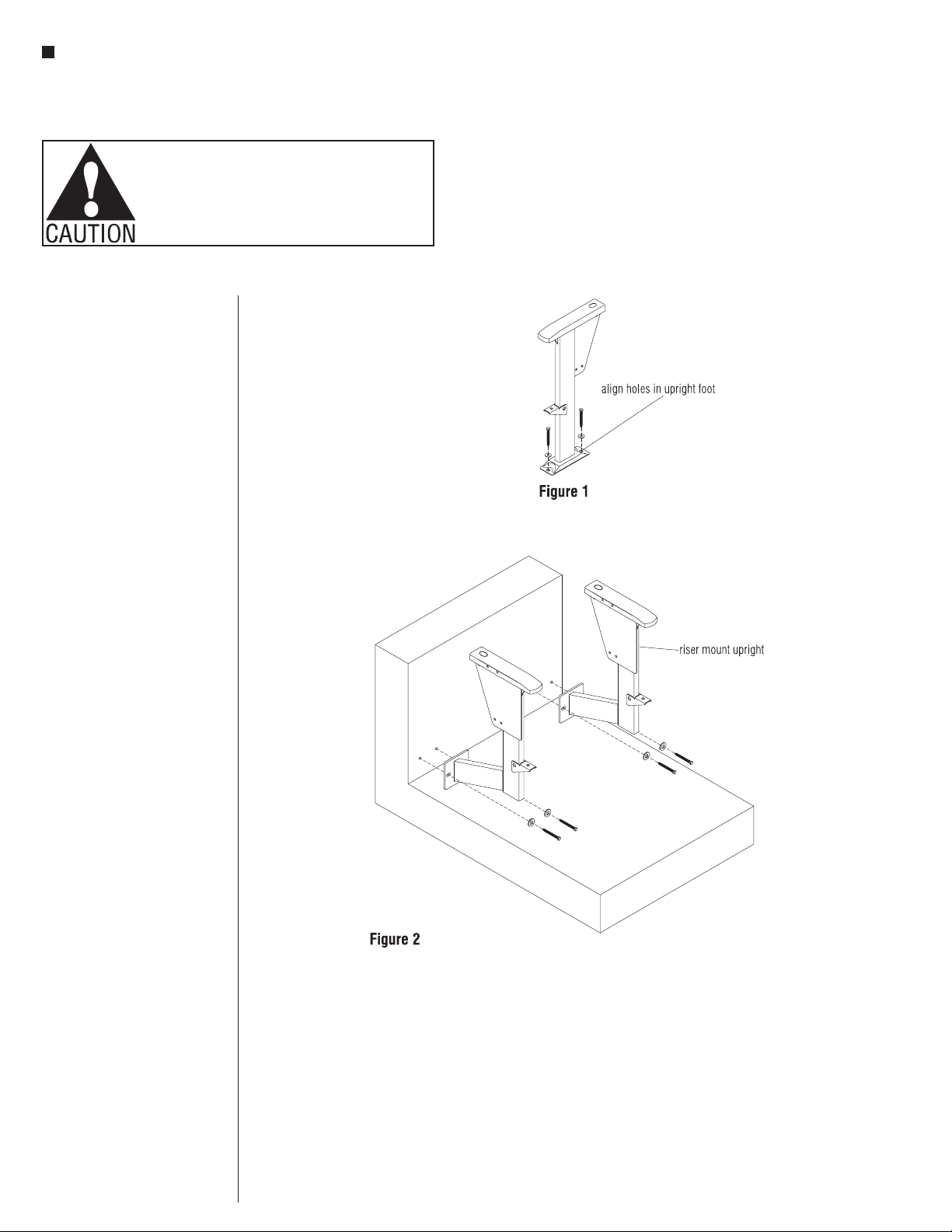

7. Locate and drill upright holes

into floor.

8. Attach uprights to the floor,

following the space-planning

layout. Install anchor bolts (not

provided) loosely to allow for

adjustment.

9. Attach backs to the uprights.

Refer to the space-planning

layout to determine location of

sizes and which top hole should

be used on the back bracket

(to determine the back angle)

(center hole is standard).

Note: Optional power & data

components should be installed

before the seats are assembled.

10. Install aisle light tube and

housing (optional).

Note: Read these assembly

instructions carefully prior to

product installation. Electrically

interconnected furnishings

must also be mechanically

interconnected. Product failure

and personal injury may result if

instructions are not followed.

Minimum Construction

Required For Upright

Installation

Wood Floors

• Minimum two layers of 3⁄4”

thick plywood

• APA rated grade plywood

• Allow minimum embedment

11⁄2” with lag screws

• Use toggle bolt if less than

11⁄2” embedment

Concrete Floors

• 3000 psi concrete

compressive strength

• 3” thick free of obstructions

for 11⁄2”

• 4” thick for riser mount free of

obstruction for 21⁄2”

• Riser to be plumb within 1⁄8°

• Minimum anchor embedment

11⁄2”

Note: Warranty null and void if KI

Lancaster Seating product line is

installed on flooring not meeting

minimum structural requirements

stated above.

Floor Fastener Requirements

Wood Floors

•5⁄16” x 13⁄4” lag bolts

• Grade 5

• 5⁄16” flat washers

• 3⁄8” toggle bolts

• All hardware to be plated

• Two bolt assemblies required

per upright

Tools Required:

• Hammer drill and bit for concrete

anchor holes

• Drill and bit for pilot holes in

wood floors

• Torx 27 head for back screws and

end panels

• Torx 20 head for electrical covers

• 9⁄16” deep well socket with ratchet

• 7⁄16” open-faced wrench

• 9⁄16” open-faced wrench

• Chalk line

• Tape measure

• Torque wrench