6

Lancaster®Auditorium Seating with Power & USB

Assembly Instructions

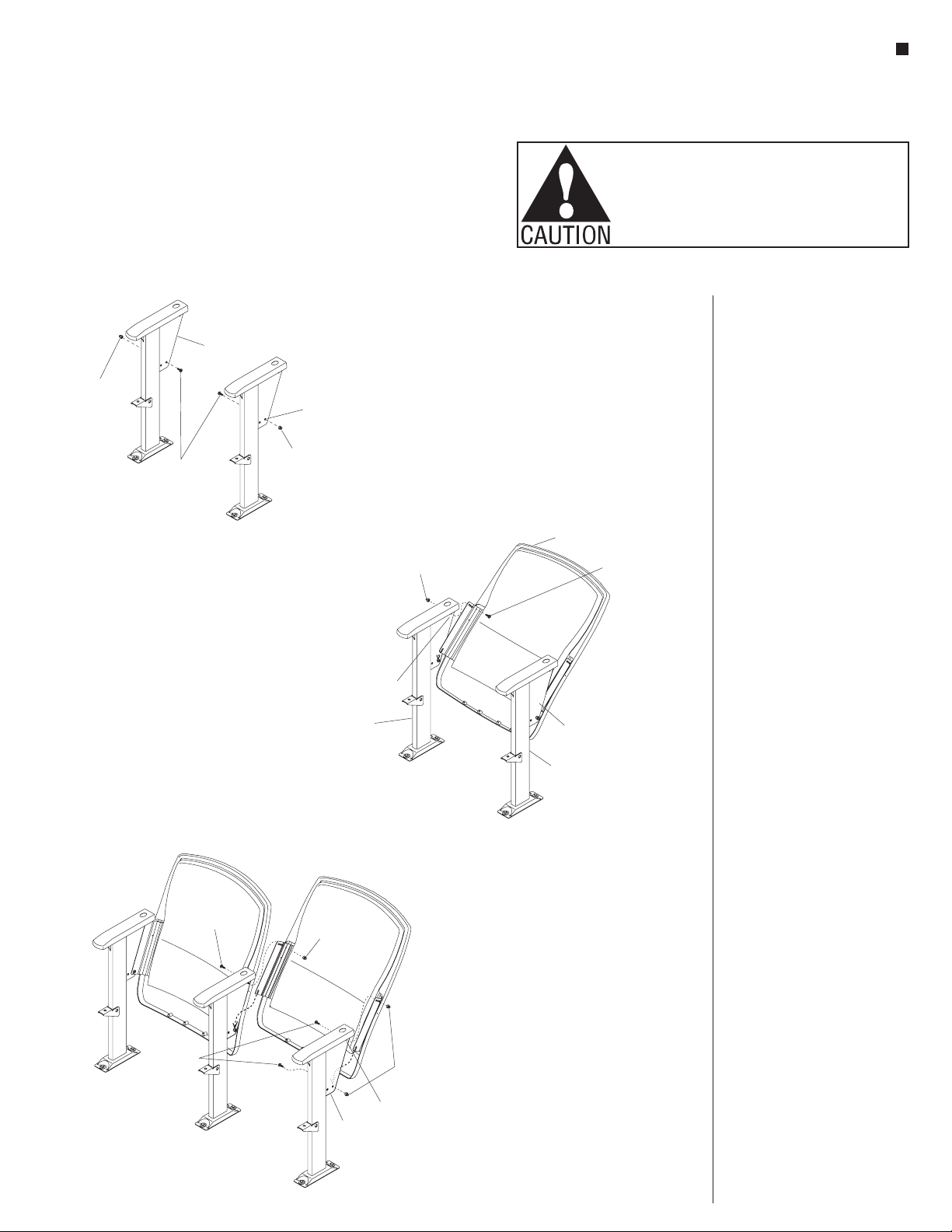

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

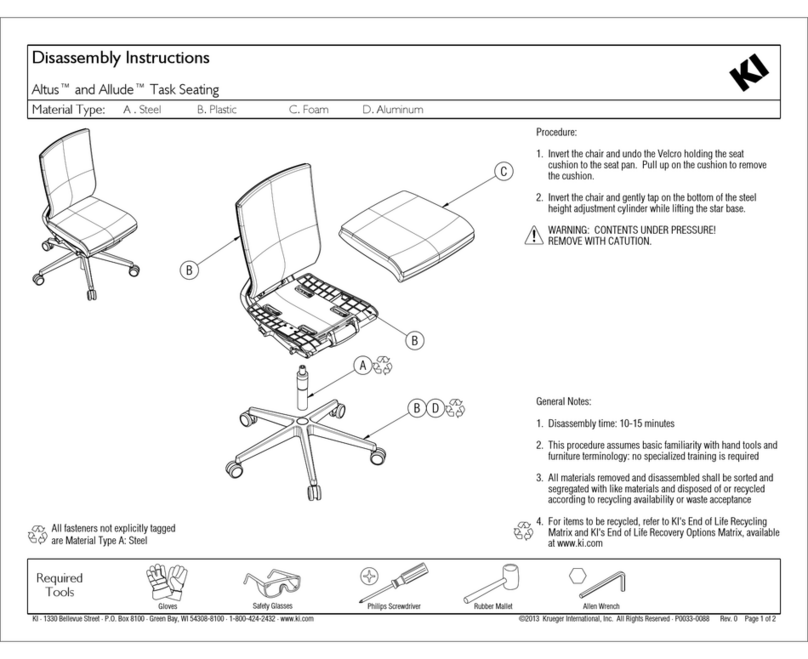

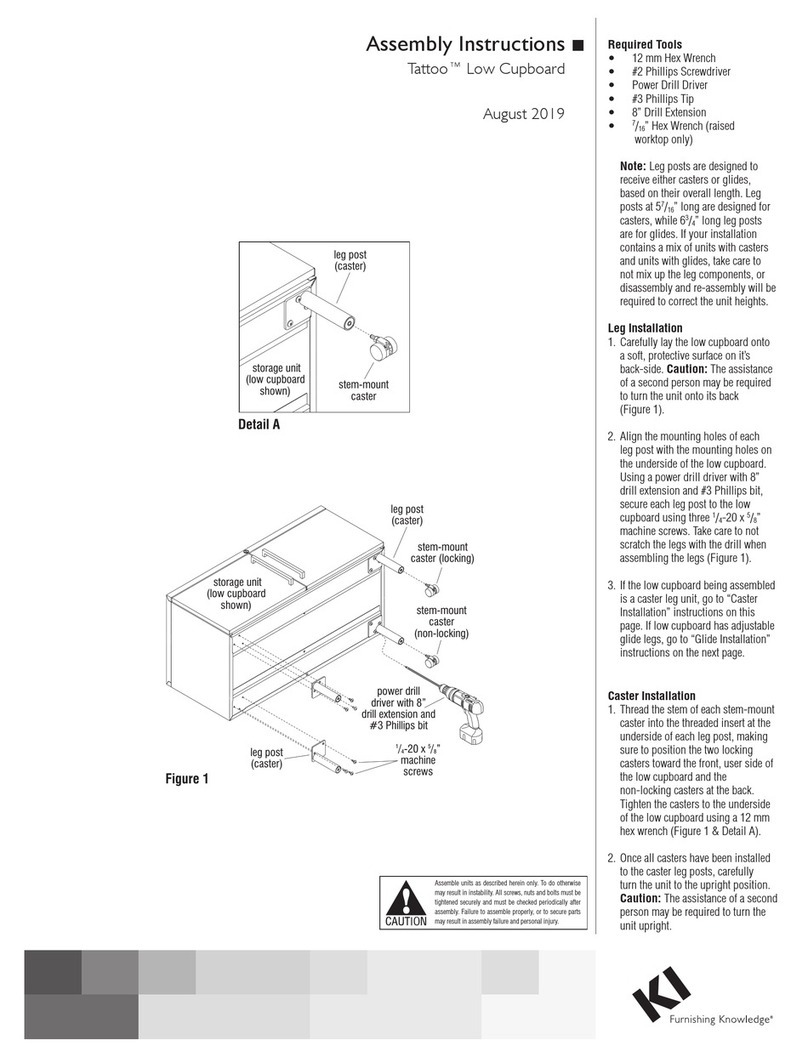

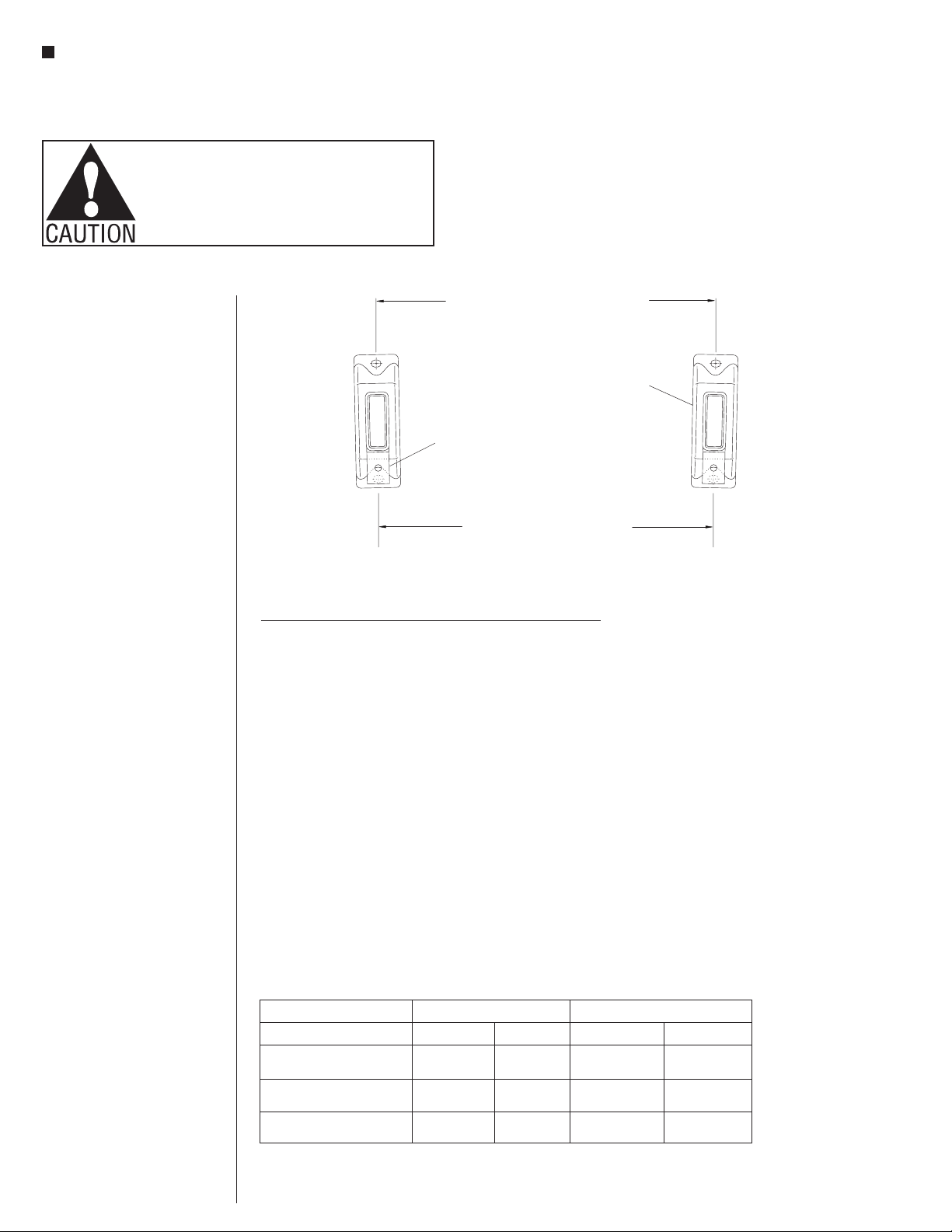

Power & USB Module

Installation

Note: Power components should

be installed before the seats are

assembled.

1. Secure the power & USB module

assembly to the module mounting

bracket using two #6 x 1/4” pan

head screws (Figure 6).

2. Secure the power & USB module

assembly with mounting bracket

to the top of the upright gusset

with two 1⁄4-20 x 5⁄8” Torx head

screws and two 1⁄4-20 acorn nuts

(Figure 6).

Note: If an end panel is attached

to an upright with a power & USB

module, the front screw of the

module mounting bracket will go

into the threaded insert in the

end panel.

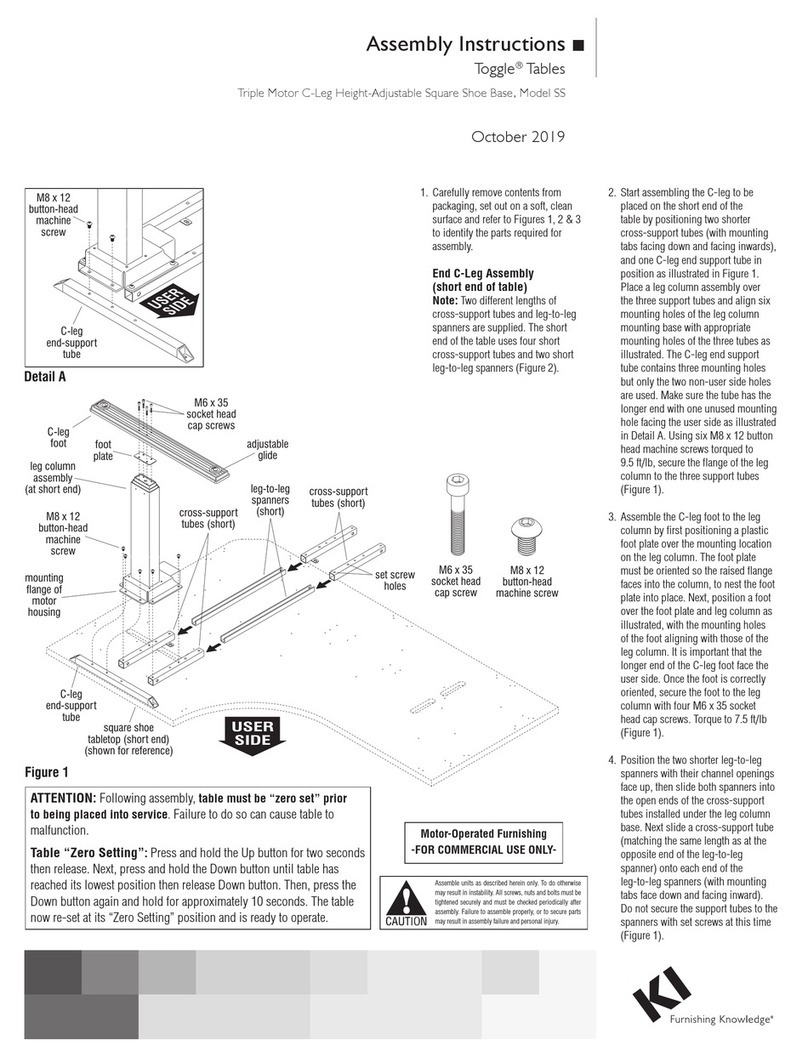

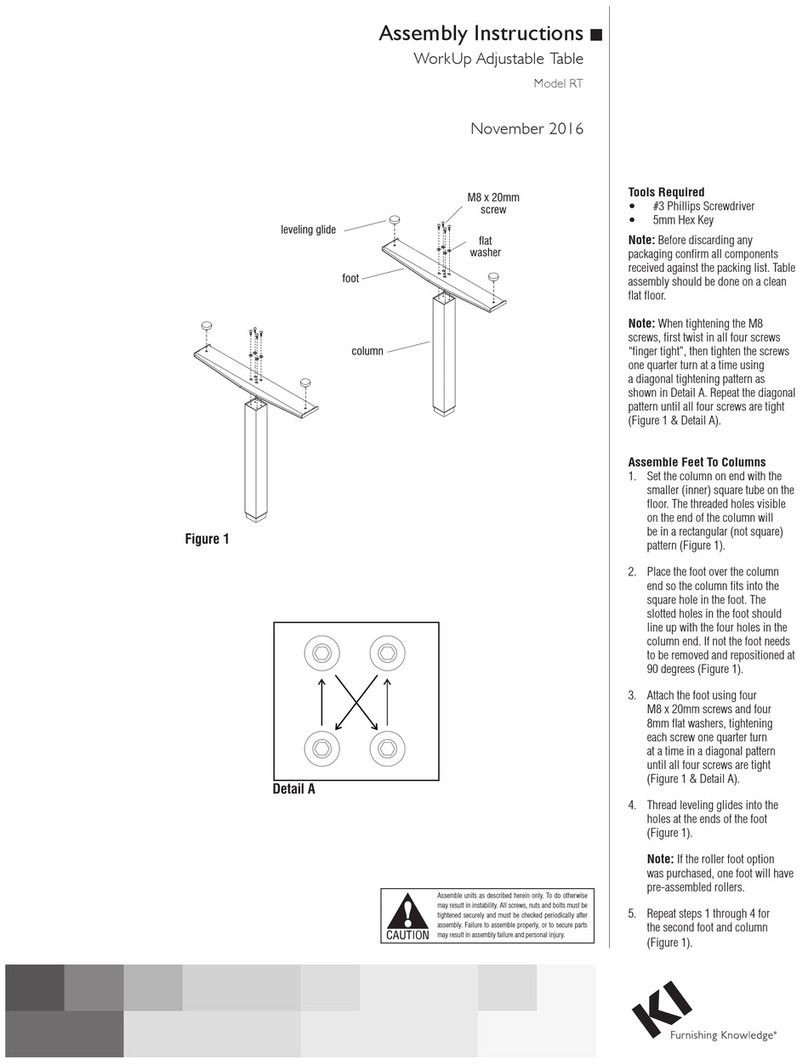

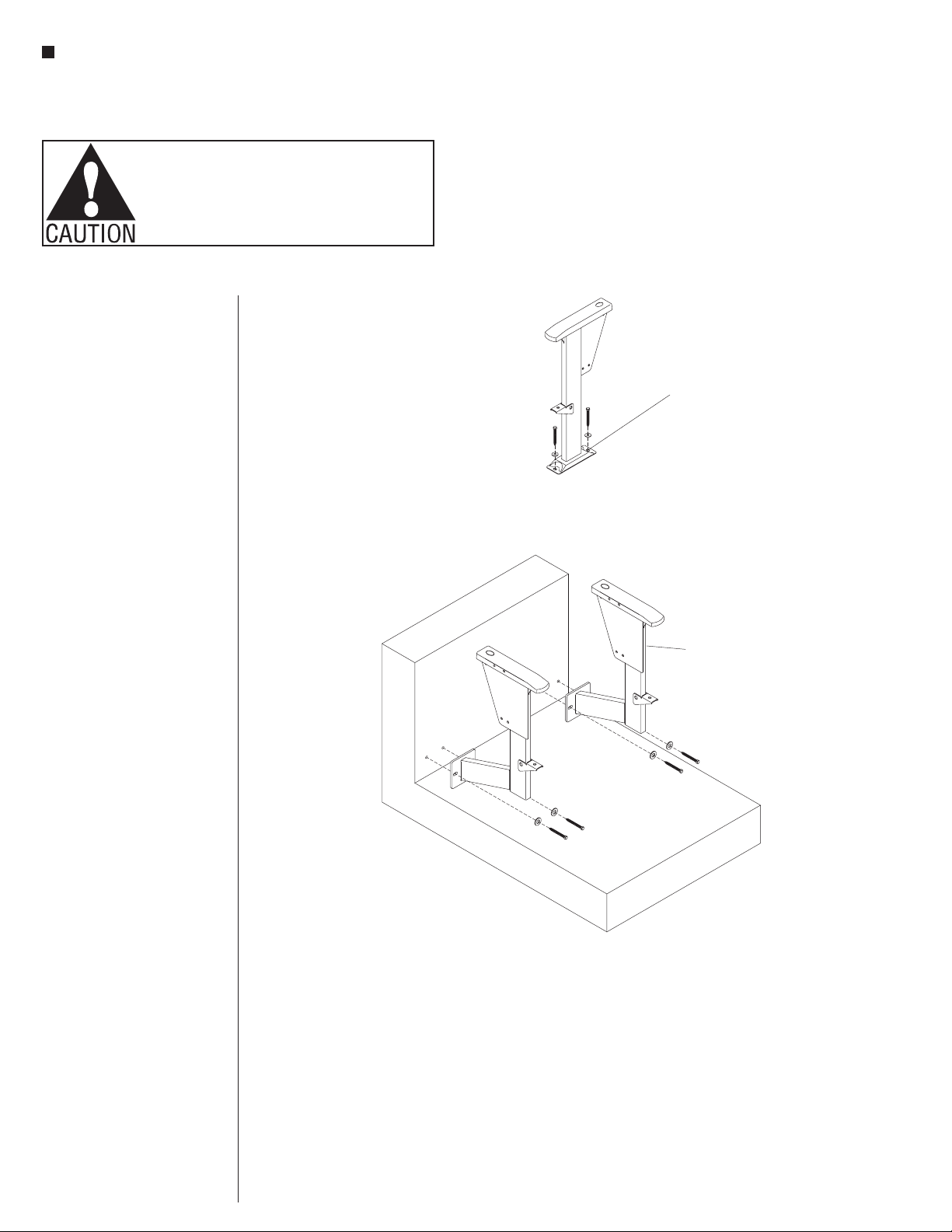

Power Infeed Installation

1. Orient and attach the power infeed

bottom bracket as illustrated, to

the foot of the upright using the

floor fastener bolt which secures

the upright to the floor (Figure 7

& Detail A).

2. Attach the top of the power infeed

outer box to the upright arm

gusset, and to the power infeed

bottom bracket below, using

1/4-20 x 5/8” Torx head screws and

1/4-20 acorn nuts (Figure 7).

3. Position the power infeed end

cover as illustrated up to the

installed power infeed outer box

and secure together using

1/4-20 x 5/8” Torx head screws and

1/4-20 acorn nuts (Figure 7).

4. Locate the power infeed harness

and components. Route the

8-wire end of the power infeed

harness through the 90° metal

connector and secure the

connector to the conduit end of

15

/ -20 x/”

torx head screws

48

#6 x/”

pan head screws

14

1

/ -20 acorn nuts

4

power & USB

module assembly

module mounting

bracket

Figure 6

power infeed

outer box

15

/ -20 x /”

Torx head screw

48

upright

arm gusset

power infeed

harness

5-wire

end

power infeed

bottom

bracket

quad connector

90° metal connector

floor

fastener

90° pulling elbow

liquid-tight

conduit

liquid-tight

connector

junction box

(not included)

#8 x /”

Torx head screw

3

8

1/ -20

acorn nut

4

power infeed

end cover

power infeed

inside cover

Figure 7

Detail A

4. Locate the power infeed harness and

components. Route the 5-wire end of the

power infeed harness through the 90-deg

metal connector and secure the connector to

the conduit end of the harness. Next run the

5-wires of the power infeed through the

power infeed inside cover and into, then out

through the corner opening of the 90-deg

pulling elbow. Twist the pulling elbow onto

the 90-deg metal connector over the power

infeed inside cover and tighten the jamb-nut

at the 90-deg metal connector side. Route

the 5-wires back into the corner, and out the

other side of the pulling elbow, then through

the liquid-tight connector, the liquid-tight

conduit and into the customer supplied

junction box. A certified electrician, following

all applicable state and local codes must

secure the components together and attach

the power infeed to building source power at

the appropriate time, verifying the electrical

integrity of the finished system (Figure 7).

Power Infeed Installation

5. Secure the power infeed inside cover to

the power infeed outer box using four #8 x

3/8” Torx head screws (Figure 7).

2. Attach the power infeed outer box to the

upright arm gusset at the top, and to the

power infeed bottom bracket below, using

1/4-20 x 5/8” Torx head screws and 1/4-20

acorn nuts (Figure 7).

1. Orient and attach the power infeed bottom

bracket as illustrated, to the foot of the

upright using the floor fastener bolt which

secures the upright to the floor (Figure 7 &

Detail A).

3. Position the power infeed end cover as

illustrated up to the installed power infeed

outer box and secure together using 1/4-20 x

5/8” Torx head screws and 1/4-20 acorn nuts

(Figure 7).

the harness. Next run the 8-wires

of the power infeed through the

power infeed inside cover and

into, then out through the rigid

conduit straight coupler. Twist

the coupler onto the 90° metal

connector, sandwiching the power

infeed inside cover and tighten

the jamb-nut at the 90° metal

connector side. Route the 8-wires

through the liquid-tight

connector, the liquid-tight

conduit and into the customer

supplied junction box. A

certified electrician, following all

applicable state and local codes

must secure the components

together and attach the power

infeed to building source power

at the appropriate time, verifying

the electrical integrity of the

finished system (Figure 7).

5. Secure the power infeed inside

cover to the power infeed outer

box using four #8 x 3/8” Torx head

screws (Figure 7).