7

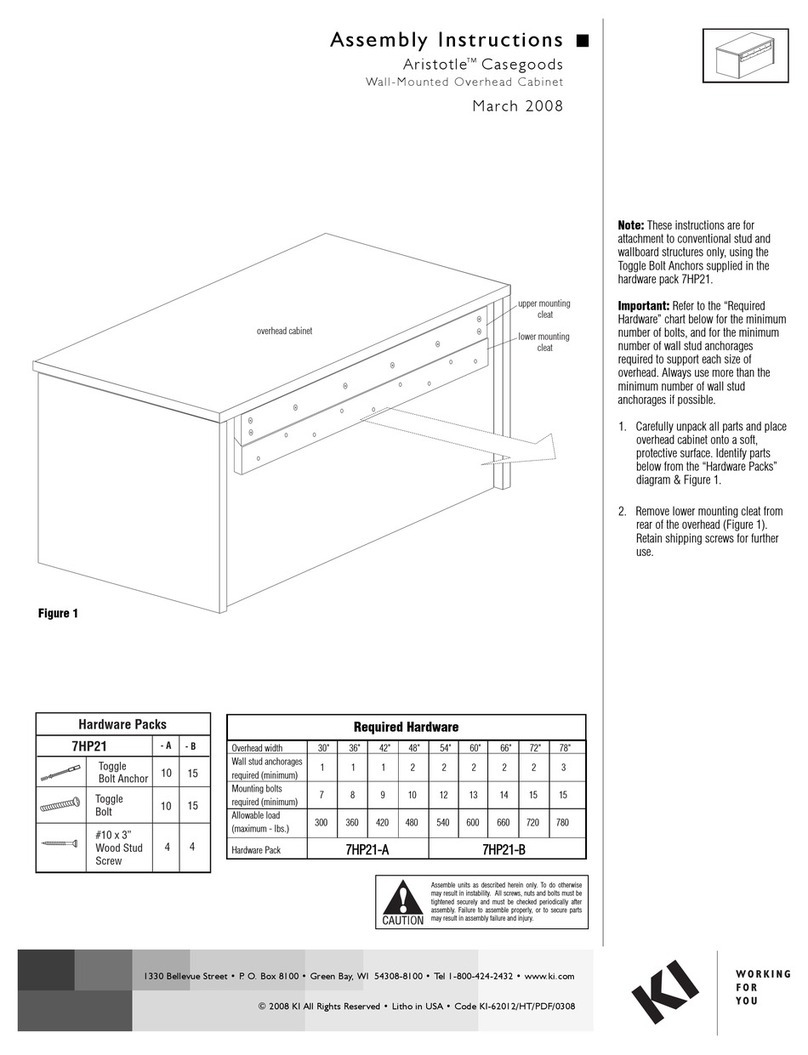

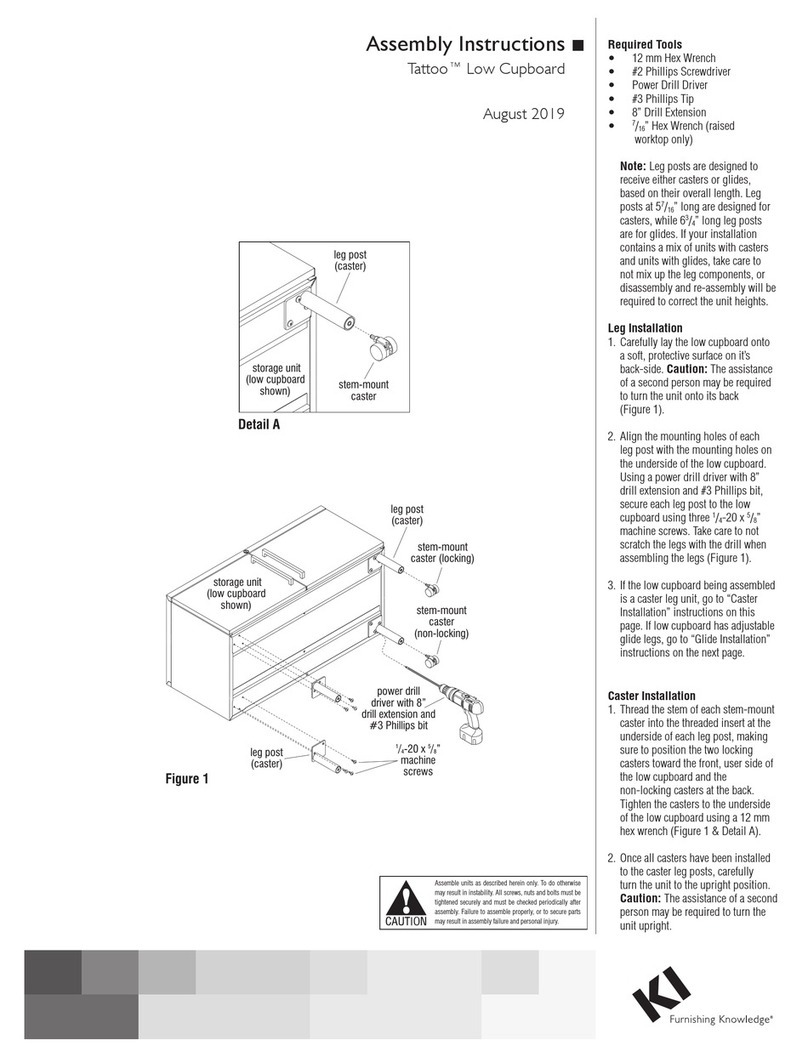

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Pirouette®Tables - Nesting-Base - Power Modules

Assembly Instructions

Dean®In-Surface Power

Module Installation

Note: The Dean In-Surface power

module is available with 3-prong

plug or Pattern electrical system.

The figures on this page illustrate

the installation of a Dean In-Surface

power module for Pattern to a

24” x 48” Pirouette Nesting-Base

table. Your configuration may vary.

Note (Power Modules for

Pattern): The Pattern electrical

system allows up to ten distribution

blocks or 50’ of jumpers from the

infeed distribution block, whichever

comes first, connected to one

standard 15-amp power cord.

Note: If tables are configured

side-to-side or back-to-back with

Pattern electrical, tables must be

mechanically connected with gangers

or splice plates before any electrical

connections are made.

Power Module

(Pattern electrical shown)

tabletop

cutout

tabletop

tabletop

tabletop

cutout

Dean In-Surface

Power Module

(Pattern electrical shown)

Detail D - (underside view)

tabletop

Dean In-Surface

Power Module

(Pattern electrical

shown)

clamp

bracket

assembly

Detail E - (underside view)

tabletop

Dean In-Surface

Power Module

(Pattern electrical shown)

clamp bracket

assembly

1. With the assembled table in the

upright position, orient the Dean

In-Surface power module as shown

and route the connector end (or

plug end) down through the tabletop

cutout in the tabletop. Press the

module down firmly into the cutout

(Figure 2 & Detail C).

2. At the underside of the Dean

In-Surface power module are two

horizontal channels which are used

to secure the clamp bracket assembly

onto each end of the module. Rotate

each clamp bracket so the screws are

facing away from the power module

as illustrated in Detail D. Insert

the top clamp bracket into the two

openings on each end of the power

module, then slide until the top

bracket is completely engaged with

the channel (Detail D).

3. Using the screws on the clamp

bracket assembly, tighten to secure

the Dean-In-Surface power module

to the tabletop (Detail E).

4. Select the appropriate data plate

adapter for the phone/data jack to

be used and carefully remove from

injection molded tree (Detail F).

Note: Jacks are sold by separate

companies and are not supplied with

the module.

5. Wire the jack appropriately to the

data plate and snap the data plate

assembly into the module grommet

opening as shown (Detail G).

Note: Depending on style of data

jack used, it may be necessary to

route the phone/data cord through

the module grommet opening and

data plate to install. Each installation

may vary.

6. Proceed to “Electrical Overview”

instructions on page 12.

BBB

CCC

DDD

EEE

FFF

Data Adapter Plates

Hubbell Nextspeed Keystone Series,

Blank (no coupler/jack)

Panduit Mini-Com Series

BBB

CCC

DDD

EEE

HHH

L-Com Keystone Modular, NETCONNECT and

110 Connect Series Modular Jack, Siemon

ZMAX Style, Allen Tel Versa Tap Series, Leviton

Quick Port Series, Belden REVConnect, HDMI

Adapter Cable.

HHH

FFF

ADC Truenet Series

Ortronics Tracjack Series

Video Monitor Jack/DB-15