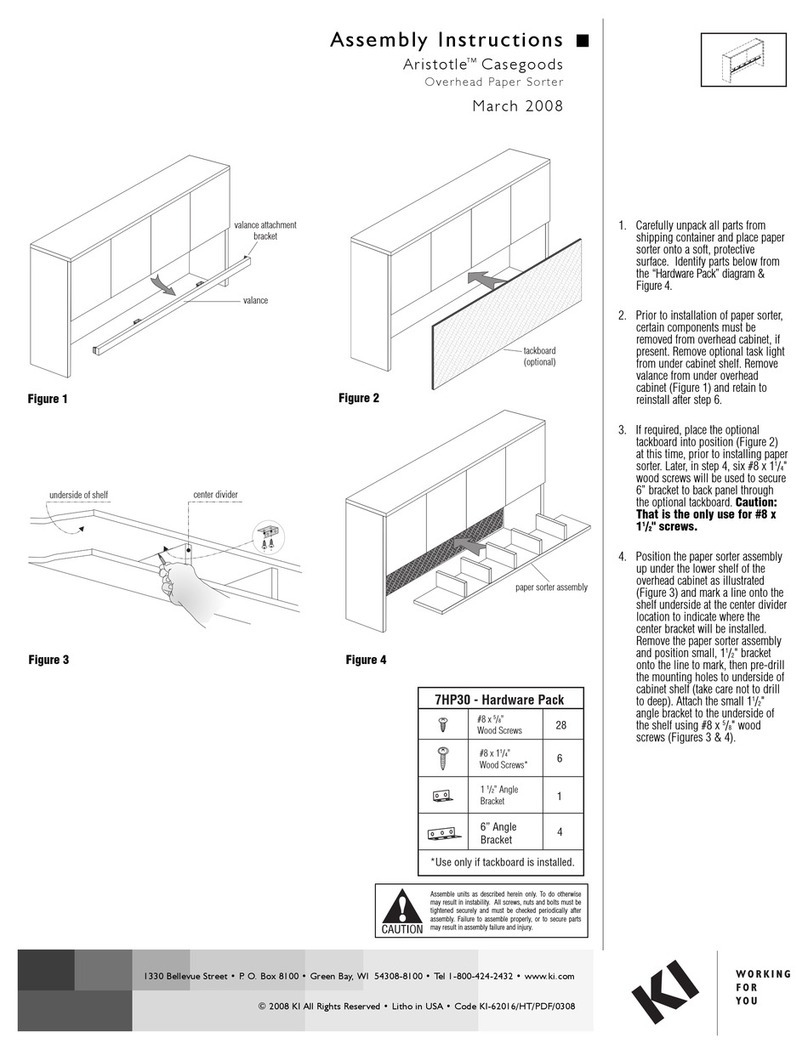

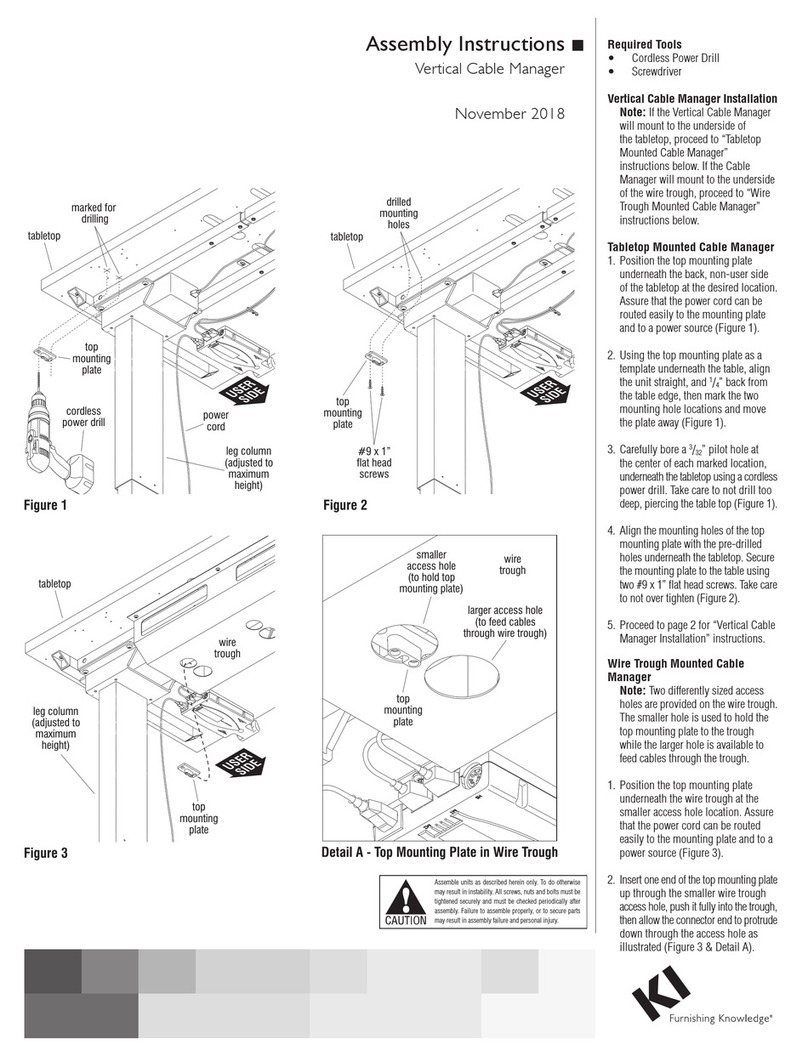

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Assembly Instructions

WorkUp Adjustable Table

Model RT

November 2016

Tools Required

• #3 Phillips Screwdriver

• 5mm Hex Key

Note: Before discarding any

packaging confirm all components

received against the packing list. Table

assembly should be done on a clean

flat floor.

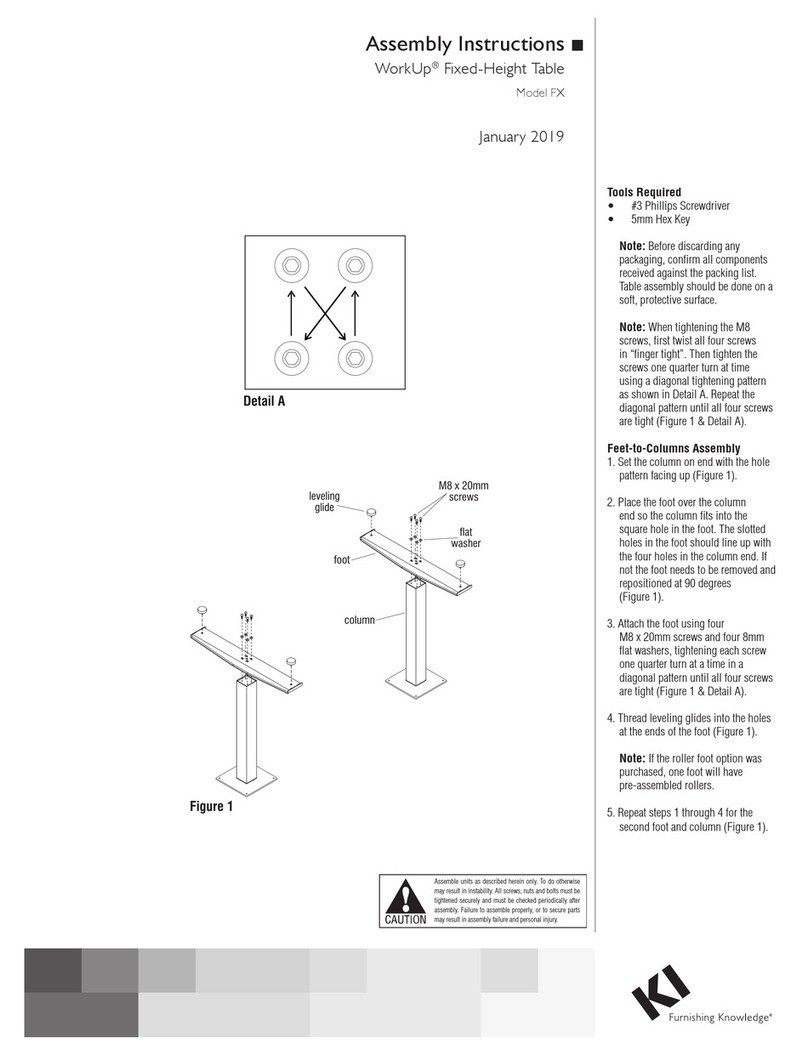

Note: When tightening the M8

screws, first twist in all four screws

“finger tight”, then tighten the screws

one quarter turn at a time using

a diagonal tightening pattern as

shown in Detail A. Repeat the diagonal

pattern until all four screws are tight

(Figure 1 & Detail A).

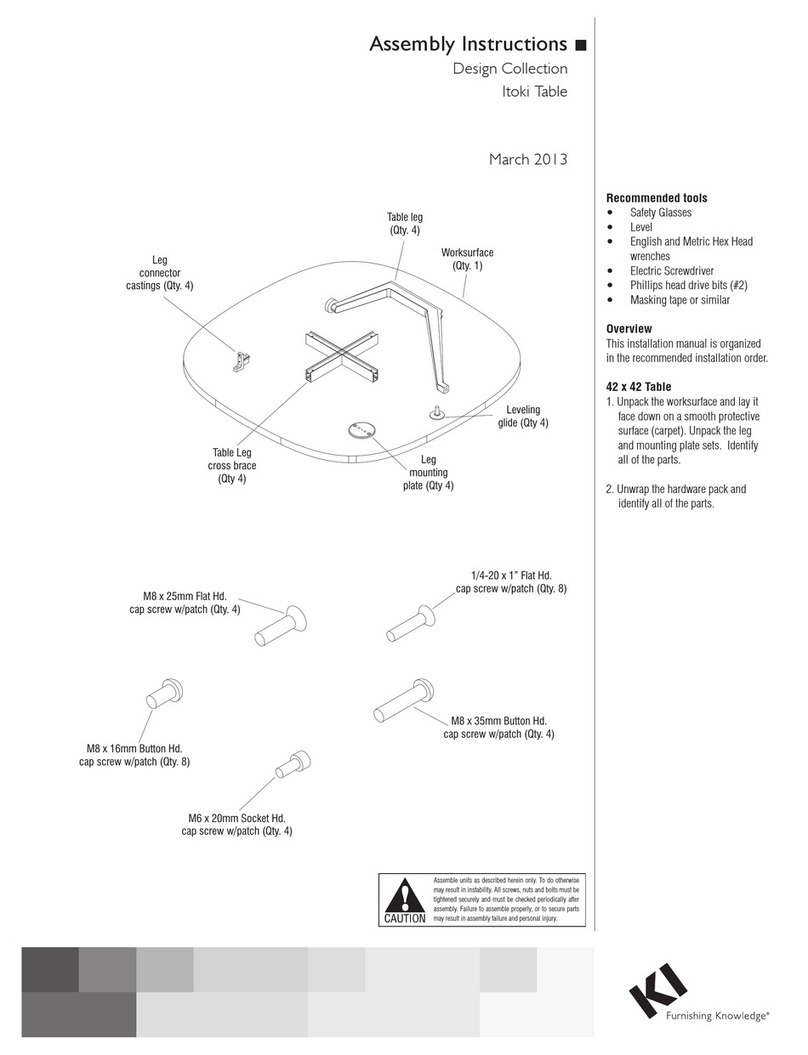

Assemble Feet To Columns

1. Set the column on end with the

smaller (inner) square tube on the

floor. The threaded holes visible

on the end of the column will

be in a rectangular (not square)

pattern (Figure 1).

2. Place the foot over the column

end so the column fits into the

square hole in the foot. The

slotted holes in the foot should

line up with the four holes in the

column end. If not the foot needs

to be removed and repositioned at

90 degrees (Figure 1).

3. Attach the foot using four

M8 x 20mm screws and four

8mm flat washers, tightening

each screw one quarter turn

at a time in a diagonal pattern

until all four screws are tight

(Figure 1 & Detail A).

4. Thread leveling glides into the

holes at the ends of the foot

(Figure 1).

Note: If the roller foot option

was purchased, one foot will have

pre-assembled rollers.

5. Repeat steps 1 through 4 for

the second foot and column

(Figure 1).

Assembly of Table

Tools Required:

·#2 Phillips Screwdriver

·#3 Phillips Screwdriver

· 5mm Hex Key (provided)

: Before discarding any packaging

confirm all components received against the

packing list. Table assembly should be done

onaclean flat floor.

(Figure1)

(Figure1)

(Figure1)

(Figure1)

Note

Note

Assemble Feet To Columns

:When tightening the M8 screws, first

twistinall fourscrews“finger tight”, then

tighten the screwsone quarter turnatatime

using adiagonal tightening pattern as shown

in Detail A. Repeat the diagonal pattern until

all fourscrewsare tight (DetailA&Figure1).

1. Setthe column on endwith thesmaller

(inner) square tubeonthe floor.The

threaded holesvisible on the endofthe

column will be in arectangular (not square)

pattern .

2. Placethe foot overthe column endso

thecolumn fits into the square hole in the

foot.The slottedholesinthe foot should line

up with the fourholesinthe column end. If

not the foot needs to be removedand

repositioned at 90 degrees .

3. Attach the foot using fourM8x20mm

screws and four8mm flat washers .

4. Threadleveling glide into the holesat

theendsofthe foot .

5. Repeatsteps 1through 4for the

second foot andcolumn.

Figure 1

leveling glide

foot

column

M8x20mm

screw

flat

washer

Detail A

Assembly Instructions

WorkUp Electric Height Adjustable Tables

Model RT

Assembly of Table

Tools Required:

·#2 Phillips Screwdriver

·#3 Phillips Screwdriver

· 5mm Hex Key (provided)

: Before discarding any packaging

confirm all components received against the

packing list. Table assembly should be done

onaclean flat floor.

(Figure1)

(Figure1)

(Figure1)

(Figure1)

Note

Note

Assemble Feet To Columns

:When tightening the M8 screws, first

twistinall fourscrews“finger tight”, then

tighten the screwsone quarter turnatatime

using adiagonal tightening pattern as shown

in Detail A. Repeat the diagonal pattern until

all fourscrewsare tight (DetailA&Figure1).

1. Setthe column on endwith thesmaller

(inner) square tubeonthe floor.The

threaded holesvisible on the endofthe

column will be in arectangular (not square)

pattern .

2. Placethe foot overthe column endso

thecolumn fits into the square hole in the

foot.The slottedholesinthe foot should line

up with the fourholesinthe column end. If

not the foot needs to be removedand

repositioned at 90 degrees .

3. Attach the foot using fourM8x20mm

screws and four8mm flat washers .

4. Threadleveling glide into the holesat

theendsofthe foot .

5. Repeatsteps 1through 4for the

second foot andcolumn.

Figure 1

leveling glide

foot

column

M8x20mm

screw

flat

washer

Detail A

Assembly Instructions

WorkUp Electric Height Adjustable Tables

Model RT