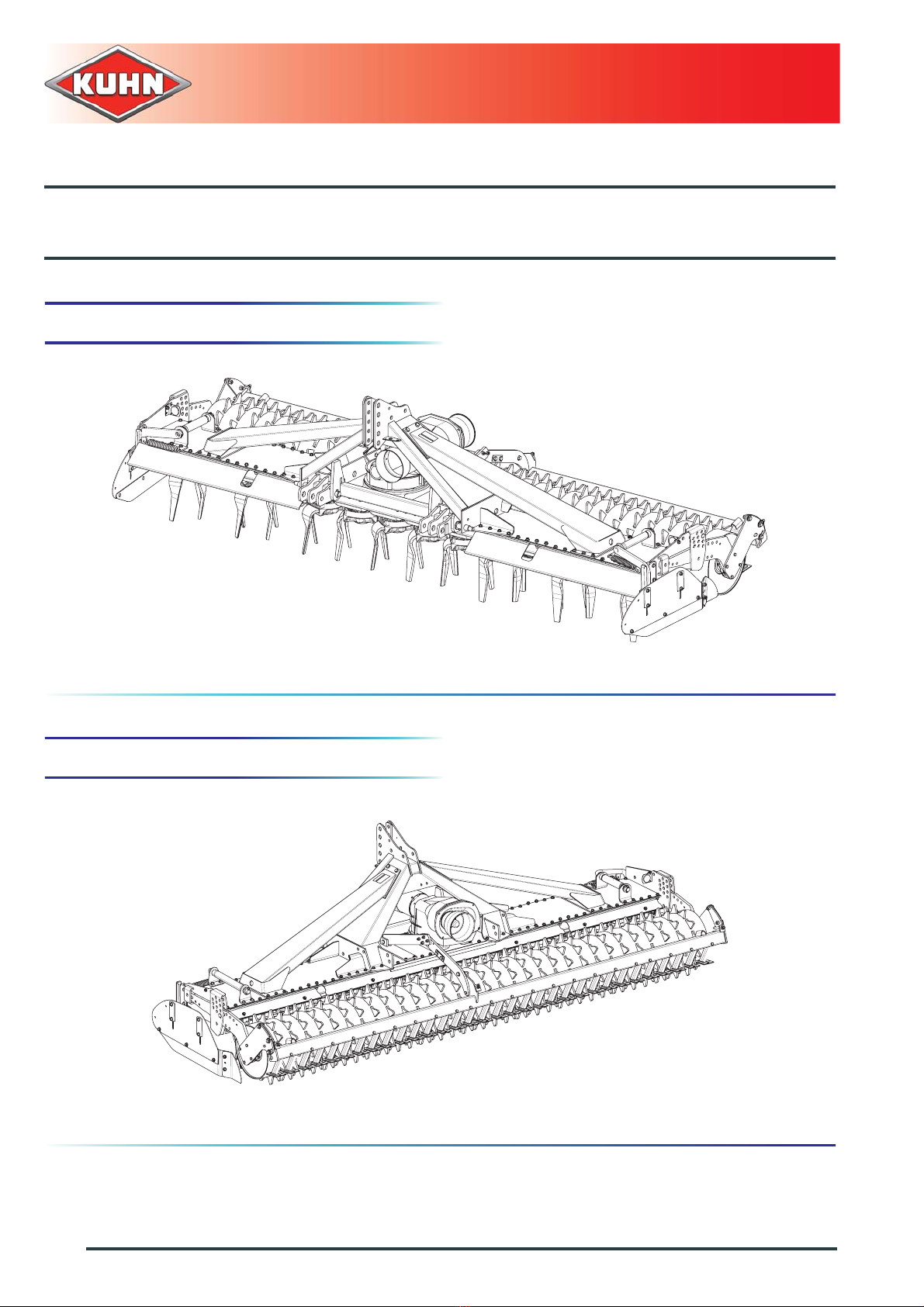

HR4004D-4504D

62. - Contents

KN208JGB_C

Power harrow

9. Optional equipment......................................................................................................63

9.1 Sets of gearwheels ........................................................................................................................ 63

9.2 Standard linkage............................................................................................................................ 64

9.2.1 Adjustment........................................................................................................................ 65

9.3 Hydraulic lift linkage....................................................................................................................... 65

9.3.1 Location and description of safety decals on the machine............................................... 66

9.3.2 Coupling and uncoupling.................................................................................................. 67

9.4.3 Removal ...........................................................................................................................77

9.4.4 Putting the machine into transport position ...................................................................... 78

9.3.5 Maintenance.....................................................................................................................72

9.3.6 Storage............................................................................................................................. 73

9.4 Rear attachment with double acting hydraulic lift........................................................................... 73

9.4.1 Location and description of safety decals on the machine............................................... 74

9.4.2 Coupling device................................................................................................................ 74

9.4.3 Removal ...........................................................................................................................77

9.4.4 Putting the machine into transport position ...................................................................... 78

9.4.5 Putting the machine into work position............................................................................. 79

9.4.6 Adjustments in working position ....................................................................................... 79

9.4.7 Maintenance.....................................................................................................................81

9.4.8 Storage............................................................................................................................. 81

9.5 Track eradicators........................................................................................................................... 82

9.5.1 Uncoupling the machine................................................................................................... 82

9.5.2 Adjustments in working position ....................................................................................... 83

9.5.3 Safety ............................................................................................................................... 84

9.5.4 Maintenance.....................................................................................................................84

9.6 Rear signalling elements................................................................................................................ 85

9.7 Lights and indicators...................................................................................................................... 85

9.7.1 Coupling and uncoupling.................................................................................................. 85

9.8 Lateral signalling equipment.......................................................................................................... 86

9.8.1 Instructions specific to France.......................................................................................... 86

9.9 Front signalling elements............................................................................................................... 86

9.9.1 Coupling and uncoupling.................................................................................................. 87

9.10 USA signalling equipment.............................................................................................................. 87

9.11 Front or rear levelling bar............................................................................................................... 88

9.11.1 Adjustments in working position....................................................................................... 88

9.12 Universal arm kit............................................................................................................................ 89

9.13 Adaptation parts for VENTA LC .....................................................................................................90

10. Maintenance and storage ............................................................................................91

10.1 Frequency chart............................................................................................................................. 91

10.2 Cleaning the machine.................................................................................................................... 92