3

TABLE OF CONTENTS

MESSAGE TO THE USER __________________________________________ 4

SAFETY INSTRUCTIONS __________________________________________ 5 - 10

SAFETY LABELS ________________________________________________ 12

LIGHTING EQUIPMENT ___________________________________________ 14

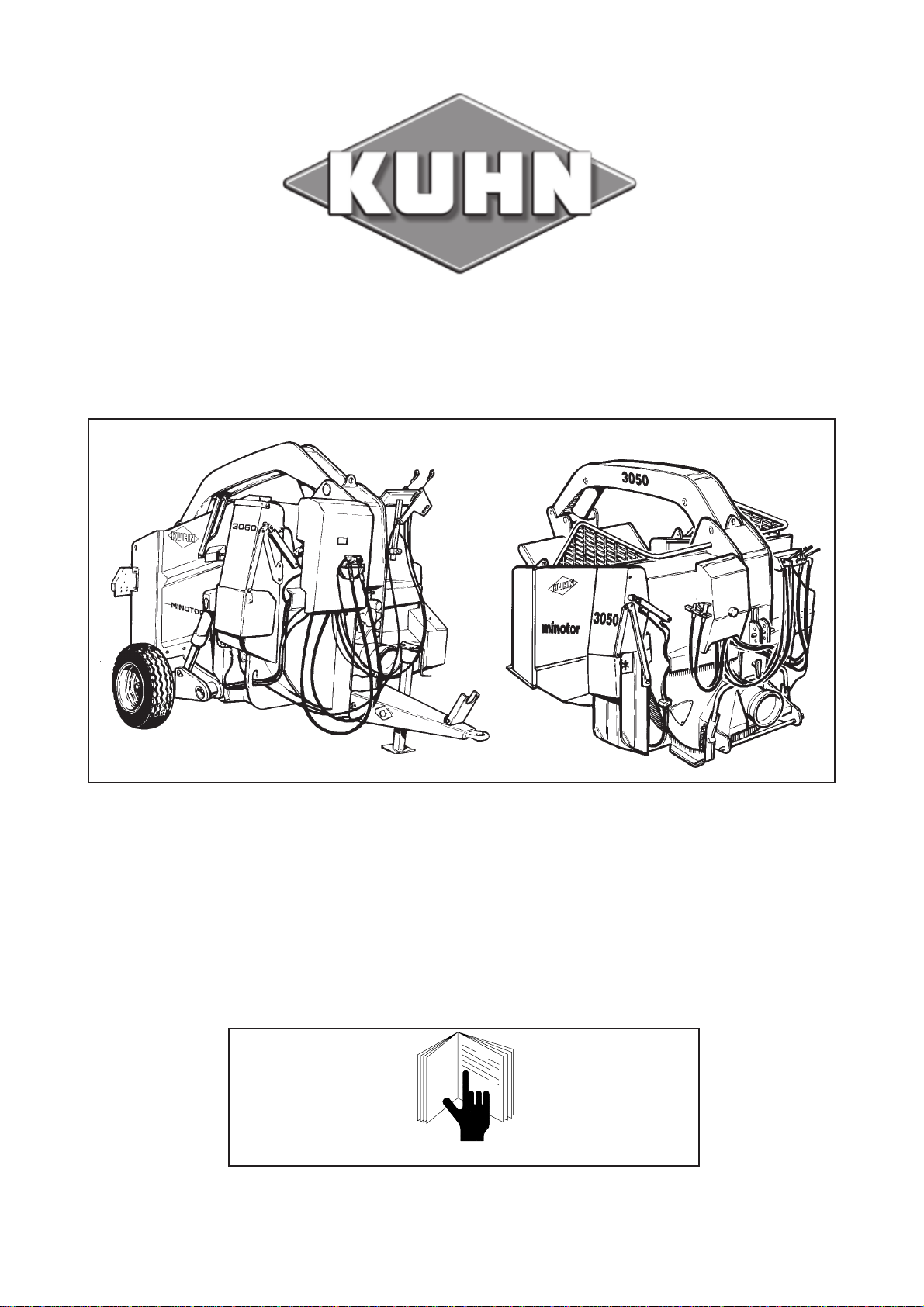

DESCRIPTION OF THE MOUNTED MINOTOR 3050 __________________ 16

DESCRIPTION OF THE SEMI-MOUNTED MINOTOR 3050

AND THE BELT-DRIVEN MINOTOR 3060 _____________________________ 18

TECHNICAL SPECIFICATIONS ______________________________________ 20

DESCRIPTION OF THE CONTROLS _________________________________ 24

Mounted/Semi-Mounted MINOTOR 3050 Remote Control Cables ____________ 24

Minotor 3060 Remote Control Cables __________________________________ 27

STARTING UP ___________________________________________________ 30

Hitching _________________________________________________________ 30

Adjusting the Position of the Controls ___________________________________ 33

Transmission ______________________________________________________ 34

Connections _____________________________________________________ 35

Preliminary Checks _________________________________________________ 37

No-Load Tests _____________________________________________________ 38

Unhitching ________________________________________________________ 38

OPERATION _____________________________________________________ 39

SilageLoading ____________________________________________________ 39

Loading Bales _____________________________________________________ 40

Transport _________________________________________________________ 41

Distributionfrom aMounted/Semi-Mounted MINOTOR 3050 _________________ 41

Distribution from a Belt-Driven MINOTOR 3060 ___________________________ 45

Using a Belt-Driven Beater Bar_________________________________________ 46

OPTIONS ________________________________________________________ 47

Free Wheel wide angle PTO shat _____________________________________ 48

Mixing Hopper + Electronic Proportioning Device __________________________ 48

Tyres _____________________________________________________________ 49

Anti-Clogging Kit for Rectangular Bales __________________________________ 50

HydraulicUnit ______________________________________________________ 51

MAINTENANCE __________________________________________________ 54

Conveyor Chain Tension _____________________________________________ 55

MaintenanceSchedule ______________________________________________ 56

Oil Change ________________________________________________________ 57

Storage ___________________________________________________________ 57

TROUBLESHOOTING GUIDE ______________________________________ 58

WARRANTY ______________________________________________________ 61