Contents

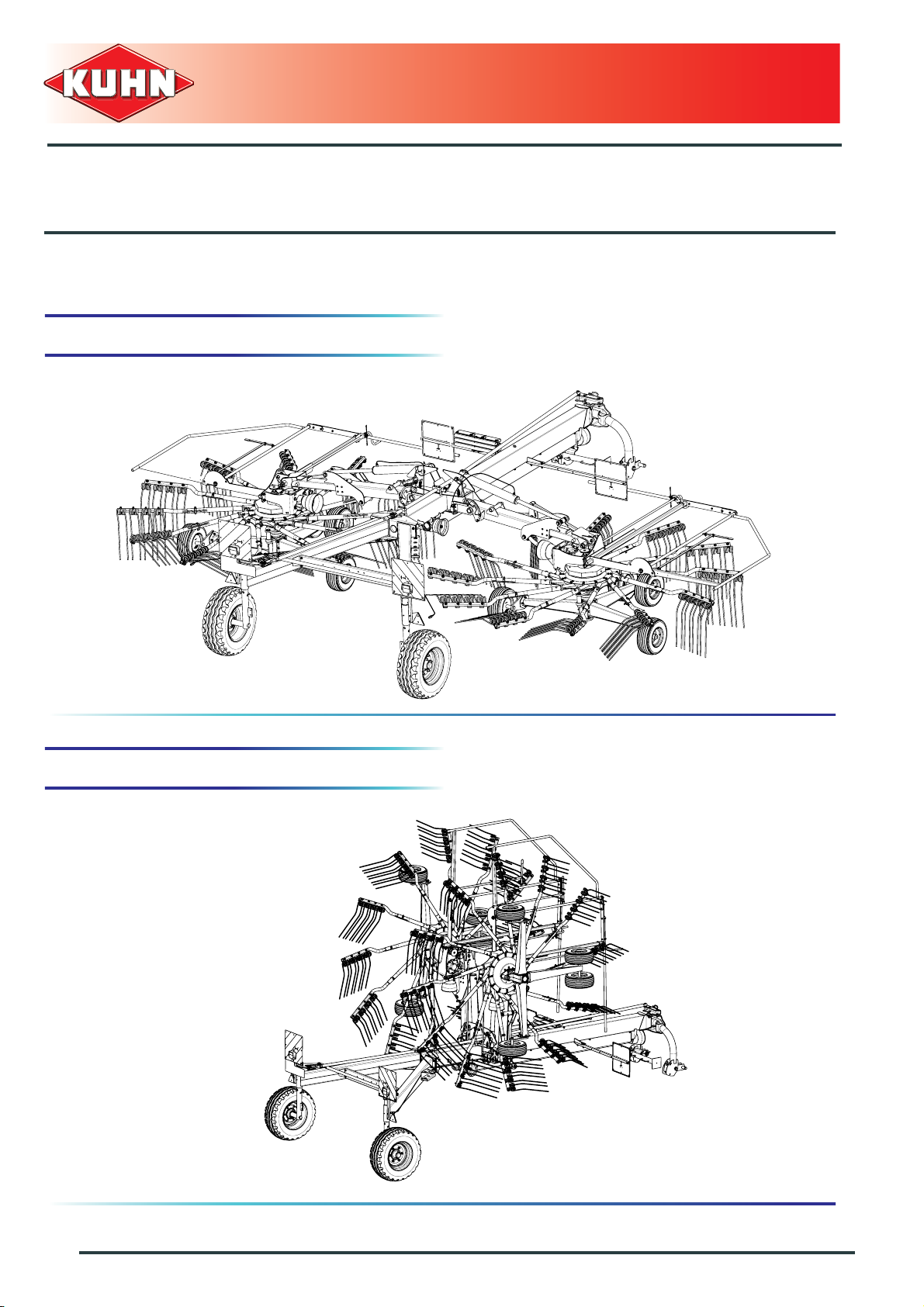

Gyrorake

GA8121

3

KN202BGB F

Instructions for work................................................................................................... 44

Putting the machine into work position.......................................................................................44

Adjustments in working position..................................................................................................46

Machine use....................................................................................................................................51

Optional equipment.....................................................................................................55

1 3/8’’ - 6 spline pto shaft...............................................................................................................55

1 3/8’’ - 6 spline pto shaft (With free wheel clutch) .....................................................................55

32x38 - 8 spline pto shaft...............................................................................................................55

Flow divider ....................................................................................................................................56

Swath curtain..................................................................................................................................57

Bogie axle suspension ..................................................................................................................58

3D axle suspension........................................................................................................................58

Check chains..................................................................................................................................58

Bogie axles .....................................................................................................................................59

SUPERBALLOON spare wheel......................................................................................................60

7 pin plug (Only for North America) .............................................................................................60

Spacer for straw .............................................................................................................................60

Clearance lights..............................................................................................................................61

SMV sign.........................................................................................................................................61

Maintenance and storage............................................................................................ 62

Frequency chart .............................................................................................................................62

Cleaning the machine....................................................................................................................63

Lubrication......................................................................................................................................63

Maintenance....................................................................................................................................71

Storage............................................................................................................................................77

Limited warranty.......................................................................................................... 78