2. - Contents

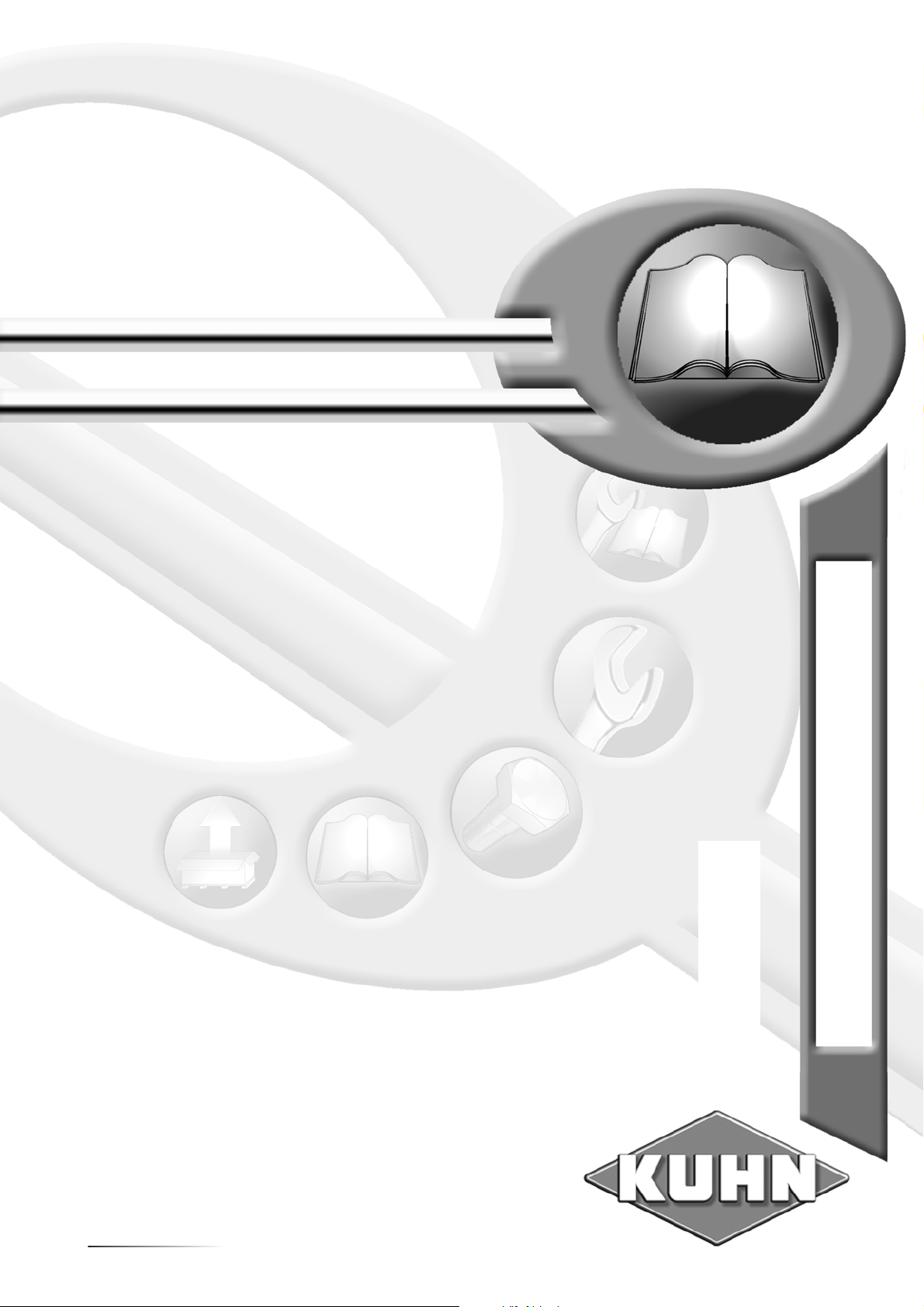

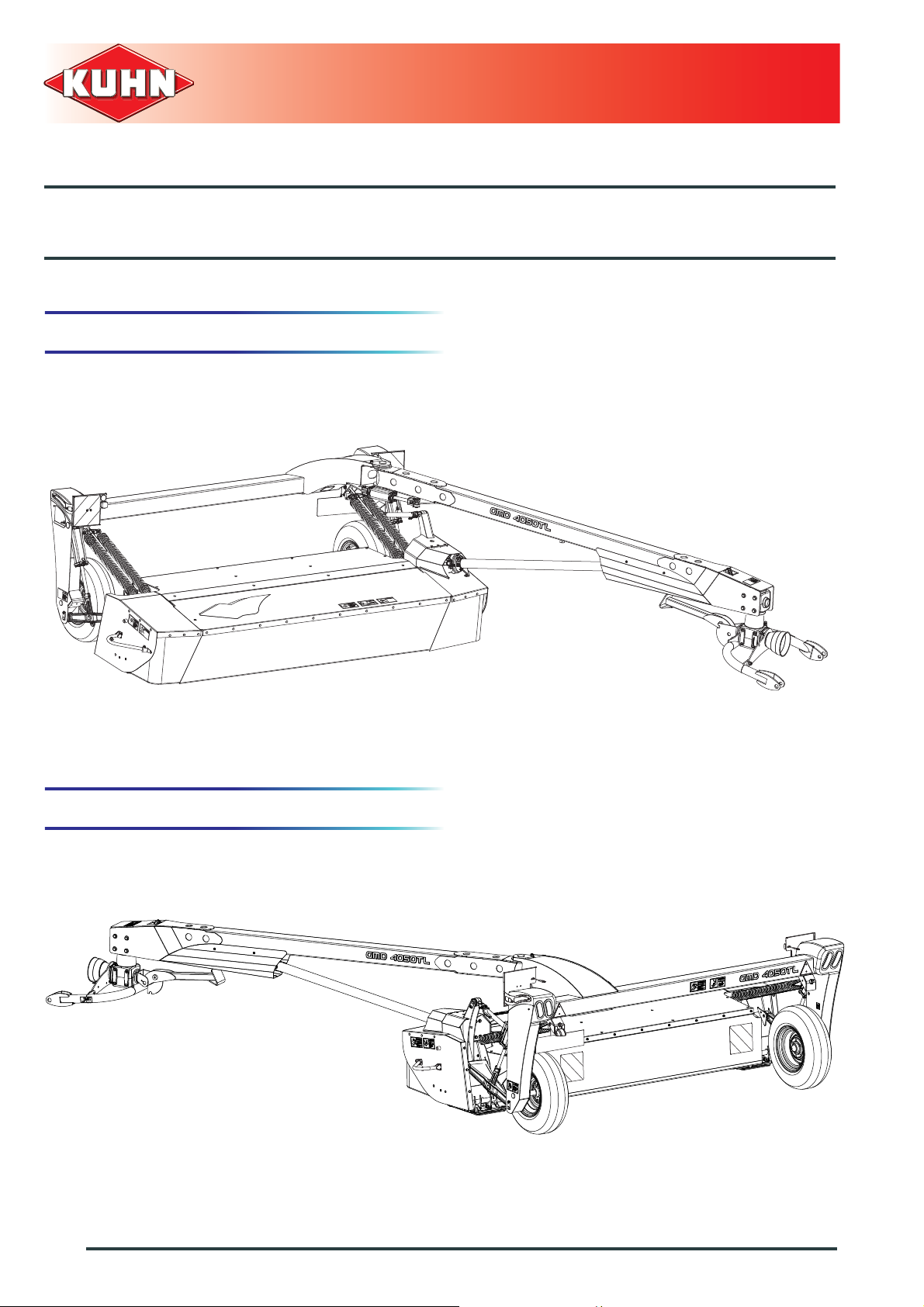

GMD 3150/3550/4050 TL CE

3

7N136AGB-A

Disk mower

8. Instructions for work................................................................................................... 35

8.1 Putting the machine into work position.......................................................................................... 35

8.2 Adjustments in working position .................................................................................................... 36

8.2.1 Cutting height................................................................................................................... 36

8.2.2 Reduced or increased ground pressure........................................................................... 40

8.3 Machine use .................................................................................................................................. 42

9. Optional equipment..................................................................................................... 43

9.1 Raised skid shoes ......................................................................................................................... 43

9.2 Secondary PTO shaft with CE shielding........................................................................................43

9.3 Secondary PTO shaft with constant velocity joint and CE shielding.............................................. 43

9.4 2-point hitch................................................................................................................................... 44

9.5 Rock guard.................................................................................................................................... 44

9.6 1000 RPM...................................................................................................................................... 44

9.7 8 spline PTO kit ............................................................................................................................. 44

10. Maintenance and storage............................................................................................ 45

10.1 Frequency chart............................................................................................................................. 45

10.2 Cleaning the machine.................................................................................................................... 46

10.3 Lubrication..................................................................................................................................... 47

10.3.1 PTO shaft ......................................................................................................................... 47

10.3.2 Grease the tongue pivot point (1)..................................................................................... 48

10.3.3 Cutterbar draining and refilling ......................................................................................... 49

10.3.4 Checking cutterbar oil level..............................................................................................51

10.3.5 90 degree gearbox draining ............................................................................................. 52

10.3.6 Draining the Gyrodine gearbox ........................................................................................ 53

10.4 Maintenance.................................................................................................................................. 54

10.4.1 Inspection of knives and securing elements..................................................................... 54

10.4.2 Knife replacement ............................................................................................................ 57

10.4.3 Disc replacement.............................................................................................................. 57

10.4.4 Outer and inner cones...................................................................................................... 60

10.5 Storage.......................................................................................................................................... 61

11. Troubleshooting guide................................................................................................ 62

12. Limited Warranty.......................................................................................................... 63